In the demanding world of high-performance manufacturing, the integrity of core components is non-negotiable. Among the various methods of metal forming, stainless steel bar forgings stand out for their unparalleled strength, reliability, and microstructural superiority. This article delves into the technical nuances of forged stainless steel bars, offering a detailed exploration that benefits engineers, procurement specialists, and industry decision-makers seeking durable solutions for critical applications.

What are Stainless Steel Bar Forgings?

A stainless steel bar forging is not merely a shaped piece of metal; it is the result of a precise thermomechanical process. It involves heating a stainless steel billet or bar stock to a specific plastic state and then applying compressive force—via hammers, presses, or ring rollers—to deform it into a near-net or net shape. This process fundamentally refines the metal's grain structure, aligning it with the contours of the final part. The outcome is a component with exceptional mechanical properties compared to its cast or machined-from-bar counterparts.

Forging is the preferred method for components where failure is not an option. The process enhances toughness, fatigue resistance, and impact strength, making forged bars indispensable in sectors like energy, heavy machinery, and aerospace. Founded in 2019, Maiterio Group specializes in such high-integrity components, including seamless rolled rings, forged shafts, and cylinders. Operating within over 50,000 square meters with multiple forging and machining lines, the company's processes are built on three decades of industry leadership, ensuring every stainless steel bar forging meets the highest global standards certified by ISO 9001, 14001, and 45001.

The Key Advantages of Choosing Forged Stainless Steel Bars

Opting for forged stainless bars over alternative manufacturing routes provides a suite of benefits that directly translate to performance and longevity in the field.

Superior Mechanical Properties

- Enhanced Strength: The forging process breaks up and refines the as-cast structure, eliminating porosity and creating a continuous grain flow. This results in higher tensile and yield strength compared to castings.

- Improved Fatigue and Impact Resistance: The homogeneous, dense microstructure withstands cyclic loading and sudden shocks far better than cast parts, significantly extending service life in dynamic applications.

- Greater Structural Integrity: Forgings have a proven history of reliability, a critical factor for safety-critical components in turbines or construction equipment where internal defects are unacceptable.

Economic and Operational Benefits

- Material Efficiency: Modern, precision forging lines can achieve smaller forging allowances, significantly reducing material waste and subsequent machining time. This is a core focus in facilities like Maiterio's, designed for optimal efficiency.

- Lifecycle Cost-Effectiveness: While the initial forging cost may be higher, the extended service life and reduced risk of catastrophic failure lead to lower total cost of ownership, making it a prudent investment.

- Production Scalability: With high-capacity facilities housing multiple forging lines, consistent quality can be maintained for both prototype and high-volume orders, ensuring supply chain stability.

Specific Applications of Forged Stainless Steel Bars

The superior properties of forged stainless bars make them the material of choice across several demanding industries. Here, we explore key application areas that address common engineering challenges.

High-Temperature and Turbine Applications

Power generation and aviation turbines subject components to extreme thermal and mechanical stress. High-temperature stainless steel bar forgings for turbine shafts are critical in these environments. Engineered from grades like AISI 630 (17-4PH) or 310, these forgings retain high strength and resist creep and oxidation at temperatures often exceeding 500°C. The forging process is paramount, as it ensures the shaft's metallurgical properties are uniform throughout its cross-section, preventing localized weakness that could lead to catastrophic failure during high-speed rotation. The ability to achieve a precise forging allowance is also vital here, minimizing the machining required on these high-value, complex geometries and preserving the optimized grain flow.

Marine and Offshore Environments

Saltwater exposure presents one of the most aggressive corrosion challenges. Components such as propeller shafts, subsea valve stems, and high-strength fasteners require the resilience of corrosion-resistant forged stainless steel bars for marine components. Austenitic grades like 316/316L, with their added molybdenum content, provide superior resistance to pitting and crevice corrosion. Forging enhances this innate corrosion resistance by creating a dense, non-porous surface with seamless grain flow. This is in stark contrast to cast surfaces, which can have micro-porosity or inclusions that act as initiation sites for corrosive attack, ultimately compromising the component's integrity in a critical marine application.

Precision Automotive and Racing Components

In the high-stakes world of automotive racing and performance engineering, minimizing mass while maximizing strength is the ultimate goal. Precision forged stainless steel bar for automotive racing parts such as connecting rods, crankshaft journals, and uprights delivers this ideal combination. The precision forging process allows for near-net-shape production, dramatically reducing excess weight compared to parts machined from solid bar stock. Simultaneously, the directional grain structure forged into the part aligns with stress contours, providing exceptional resistance to the enormous cyclical loads, torsional forces, and vibrations experienced on the racetrack, thereby enhancing durability and performance.

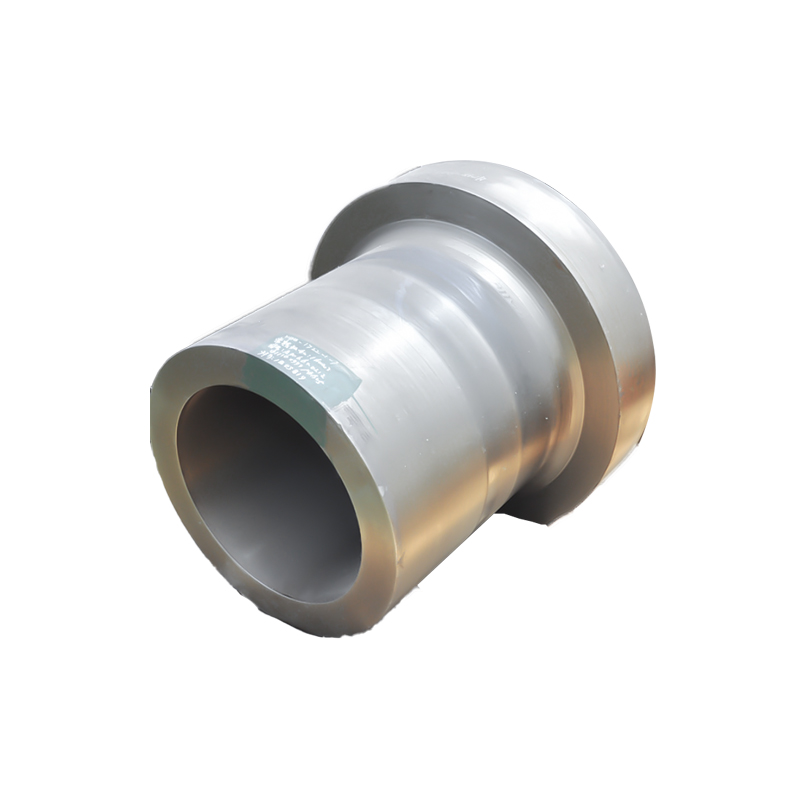

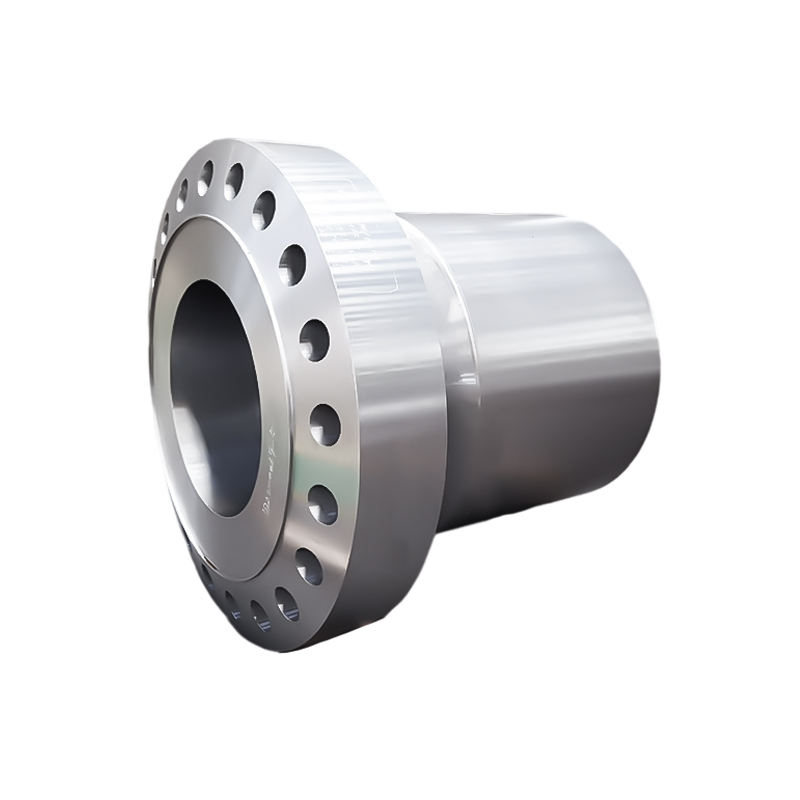

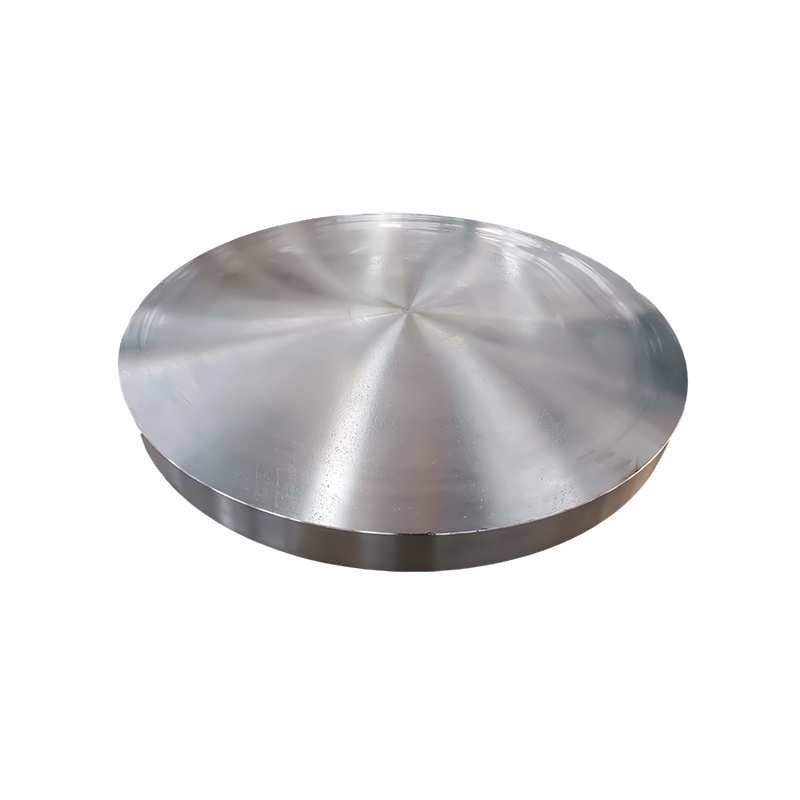

Heavy Industrial and Pressure Equipment

Industrial pressure vessels, reactors, and large-scale processing equipment demand absolute integrity to safely contain gases and liquids under high pressure. Utilizing large diameter forged stainless steel bar stock for pressure vessels for critical elements like nozzle necks, manway flanges, and pump shafts is a standard best practice. Forging delivers superior through-thickness properties, eliminating the risk of laminations, inclusions, or anisotropic weaknesses that can be inherent in rolled plate or cast products. The isotropic strength of a forged bar—meaning its mechanical properties are consistent in all directions—is non-negotiable for ensuring a uniform pressure boundary and preventing leak paths.

Aerospace and Defense Systems

Aerospace applications, particularly landing gear, actuator systems, and engine mounts, require materials that offer an exceptional strength-to-weight ratio alongside supreme reliability. Custom alloy forged stainless steel bars for aerospace landing gear meet this challenge. These are often produced from high-strength precipitation-hardening (PH) grades like 15-5PH or custom maraging steels. The forging process is meticulously controlled not only to shape the part but, more importantly, to develop a fine, uniform microstructure that is then further optimized through precise heat treatment. This results in a component with unparalleled toughness, fatigue crack growth resistance, and the ability to withstand the immense impact loads of landing for tens of thousands of cycles, a critical safety requirement.

Forging Processes for Stainless Steel Bars: Open-Die vs. Closed-Die

The choice of forging method significantly impacts the final part's characteristics, cost, and suitable applications. Selecting between open-die and closed-die forging is a fundamental decision in the component design phase.

Open-die forging involves deforming the metal between flat or simply shaped dies that do not fully enclose the workpiece, allowing for flexibility in size and shape. It is ideal for large, relatively simple shapes like large-diameter shafts, discs, or pre-forms for further processing. In contrast, closed-die (or impression-die) forging confines the metal within two dies containing a precise cavity that imparts the final shape to the workpiece. This method is best suited for producing more complex, high-volume components with tighter dimensional tolerances.

| Aspect | Open-Die Forging | Closed-Die Forging |

| Die Design & Cost | Simpler, lower-cost dies with minimal custom tooling. | Complex, high-cost dies that are specific to each part geometry. |

| Part Complexity | Best for large, simple shapes (bars, blanks, rings, hollows). | Excellent for intricate, net- or near-net-shape parts with details. |

| Material Utilization | Generally higher forging allowance, requiring more secondary machining. | Higher material efficiency with less waste (though flash is generated). |

| Production Volume | Excellent for low-volume, custom, or one-off pieces and large singular items. | Economically viable for medium to high production runs due to tooling amortization. |

| Grain Flow & Strength | Provides excellent grain refinement and strength enhancement in the working direction. | Creates superior, multi-directional grain flow that follows the complex part contour precisely. |

The selection often depends on the project's scale and end-use. For example, a large diameter forged stainless steel bar stock for pressure vessels is typically produced via open-die forging, while a complex precision forged stainless steel bar for automotive racing parts would likely use closed-die methods. Maiterio Group's expertise spans both, with dedicated open-die lines for large shafts and ring rolling, and the capability to manage projects requiring closed-die precision, ensuring the optimal process is selected for each stainless steel bar forging requirement.

Selecting the Right Stainless Steel Grade for Your Forging Project

Material selection is the cornerstone of a successful forging project. The chosen stainless steel grade directly dictates the component's performance in its operational environment. The selection is a balance between mechanical properties, corrosion resistance, fabricability, and cost.

Common Forging Grades and Their Properties

- Austenitic (304/304L, 316/316L): The most widely used group, known for excellent corrosion resistance, formability, and toughness. Grade 316/L, with molybdenum, is the standard for corrosion-resistant forged stainless steel bars for marine components. Their non-magnetic nature and good weldability make them versatile.

- Martensitic (410, 420, 440C): Magnetic and heat-treatable, these grades achieve high strength and hardness. They offer moderate corrosion resistance and are ideal for applications requiring wear resistance, such as valves, pump shafts, and cutlery.

- Precipitation-Hardening (17-4PH, 15-5PH): These alloys can be heat-treated after forging to achieve very high strength levels while maintaining good corrosion resistance. This makes them prime candidates for high-temperature stainless steel bar forgings for turbine shafts and custom alloy forged stainless steel bars for aerospace landing gear, where the strength-to-weight ratio is critical.

- Duplex (2205, 2507): These grades combine austenitic and ferritic structures, offering yield strength approximately double that of standard 304/316, along with excellent resistance to stress corrosion cracking. They are increasingly used in offshore, chemical, and pulp & paper industries.

Factors Influencing Grade Selection

- Operating Environment: This is paramount. Consider exposure to chlorides, acids, caustics, and operating temperature ranges (cryogenic to elevated).

- Mechanical Requirements: Define the necessary yield strength, tensile strength, impact toughness (Charpy values), fatigue life, and hardness.

- Fabrication Needs: Assess requirements for weldability, machinability post-forging, and the specific heat treatment cycles the grade requires.

- Regulatory & Standard Compliance: The component may need to conform to specific ASTM, ASME, EN, or customer material specifications for traceability and certification.

Partnering with a forge that has strong material supply chain integration is advantageous. As the largest customer of a top-three alloy steel mill, Maiterio Group guarantees access to premium-grade materials with optimal pricing and rigorous quality control, validated through their own extensive forging consumption.

The Role of Machining in Finishing Forged Stainless Bars

Forging provides the foundational strength and near-net shape, but precision machining is the essential final step to meet exacting dimensional, geometric, and surface finish requirements. Virtually all stainless steel bar forgings undergo some level of machining.

Common Machining Operations

- Turning and Milling: CNC lathes and machining centers are employed to achieve precise diameters, lengths, tapers, and complex contours. This is where the "forging allowance" is systematically removed to reveal the final part dimensions.

- Drilling and Tapping: These processes create bolt holes, lubrication channels, mounting holes, and threaded connections necessary for assembly and function.

- Grinding and Polishing: Used to attain superior surface finishes (e.g., Ra values) for sealing surfaces, aesthetic requirements, or to meet specific fatigue performance criteria by removing surface imperfections.

Benefits of an Integrated Forge-and-Machine Workflow

Having forging and machining under one roof, as practiced by Maiterio Group with its 70+ CNC machines, offers significant advantages:

- Quality Continuity: A single point of control from raw material to finished part ensures consistency in quality standards and documentation.

- Reduced Lead Times: Eliminating the need to transport forgings to an external machine shop streamlines the production schedule.

- Technical Synergy: Machinists work directly with forging engineers, allowing for feedback on optimal forging shapes to improve machinability and reduce cycle times.

- Cost Optimization: Integrated planning minimizes material handling, logistics, and administrative overhead, providing a more cost-effective total solution.

This vertical integration is crucial for serving sectors like energy and heavy machinery, where complex, fully finished components are required for direct assembly into larger systems.

Frequently Asked Questions (FAQ)

1. Why are forged stainless steel bars stronger than cast or machined bars?

Forging refines the metal's coarse as-cast grain structure into a fine, directional grain flow through controlled plastic deformation. This process eliminates internal voids (porosity), gas pockets, and chemical segregations, resulting in a denser, more homogeneous microstructure [1]. This leads to superior tensile strength, impact resistance, and especially fatigue life compared to cast parts. Parts machined from stock bar retain the original mill product's grain structure, which is not oriented to the part's shape, offering no improvement in these key mechanical properties.

2. What are the main cost drivers for a custom stainless steel bar forging project?

The primary cost factors are multi-faceted: the alloy grade (exotic or high-performance alloys cost more); the part complexity and size (dictating forging steps and equipment size); the chosen forging process (closed-die requires high initial tooling investment); the forging allowance (impacts material cost and machining time); the order volume; and the scope of post-forging operations (machining complexity, heat treatment, non-destructive testing). A detailed design-for-manufacturability review with your forging partner can help optimize these factors.

3. How does the "forging allowance" impact my project's cost and timeline?

The forging allowance is the extra material intentionally left on the forging to be removed during machining. A smaller, well-optimized allowance, achievable through precision forging practices and expert die design, directly reduces raw material costs. More importantly, it significantly decreases machining time, tool wear, and associated costs. Advanced forging operations focus on minimizing this allowance, which streamlines the entire manufacturing workflow, reduces lead time, and lowers the total project cost.

4. Can you forge very large or very small stainless steel components from bar stock?

Absolutely. Forging is remarkably scalable. Open-die forging is specifically engineered for massive components, such as large diameter forged stainless steel bar stock for pressure vessels or marine shafting, which can weigh many tons and measure several meters in length. Conversely, precision closed-die forging is capable of producing small, intricate parts like surgical instrument components or delicate precision forged stainless steel bar for automotive racing parts with high dimensional accuracy and excellent surface finish.

5. What quality certifications should I look for in a forging supplier?

Reputable suppliers will hold internationally recognized management system certifications: ISO 9001 for Quality Management is essential. ISO 14001 (Environmental) and ISO 45001 (Health & Safety) indicate a responsible operation. For specific industries, look for AS9100 (Aerospace), NADCAP accreditations (especially for heat treatment and NDT), or PED/AD2000 for pressure equipment. Crucially, ensure they provide full material traceability (mill certificates) and have robust in-house Non-Destructive Testing (NDT) capabilities like Ultrasonic Testing (UT) and Liquid Penetrant Testing (PT).

Conclusion

Stainless steel bar forgings represent the pinnacle of strength, reliability, and performance for critical engineering applications. From the depths of the ocean to the heights of the atmosphere, the unique benefits of a forged grain structure make it the manufacturing method of choice where failure is not an option. Whether your need is for high-temperature turbine shafts, corrosion-resistant marine components, precision racing parts, large diameter pressure vessel stock, or custom aerospace landing gear alloys, understanding the intricate interplay between material science, forging process selection, and precision finishing is key to specifying the optimal component. Partnering with a technologically advanced, vertically integrated manufacturer with deep material and process expertise ensures access to a seamless journey from alloy selection to final machining, guaranteeing a part that meets the most stringent global standards for performance, safety, and longevity.

References

[1] ASM International Handbook Committee. (2005). ASM Handbook, Volume 14A: Metalworking: Bulk Forming. ASM International. (This authoritative reference details the metallurgical principles behind grain refinement and property enhancement in forging processes, explaining the superiority of forged microstructure.)

English

English Español

Español русский

русский