In the world of high-performance industrial components, stainless steel forgings stand as a cornerstone of reliability and strength. This manufacturing process transforms solid stainless steel billets into parts with superior mechanical properties, making them indispensable for demanding applications. This comprehensive guide delves into the intricacies of stainless steel forging, exploring its methods, benefits, and critical role across various sectors. We will also examine how modern manufacturers leverage advanced capabilities to meet the stringent standards of global industries.

What are Stainless Steel Forgings?

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. When applied to stainless steel—an alloy renowned for its corrosion resistance and strength—the result is a component with an aligned grain structure, enhanced toughness, and improved structural integrity. Unlike cast or machined parts, forged components exhibit greater reliability under stress, fatigue, and impact, which is why they are preferred for mission-critical applications.

Key Characteristics of Forged Stainless Steel

Superior Metallurgical Properties

- Grain Flow Refinement: The forging process aligns the steel's grain structure to follow the contours of the part, eliminating porosity and voids.

- Enhanced Density: The compressive force creates a denser, more homogeneous material compared to casting.

- Improved Mechanical Traits: This leads to greater tensile strength, fatigue resistance, and impact toughness.

Why Forging Outperforms Other Methods

When comparing manufacturing techniques, forging offers distinct advantages for stainless steel. For instance, a forged stainless steel valve body will typically have a longer service life and higher pressure rating than its cast counterpart due to its superior integrity.

| Property | Forging | Casting | Machining from Bar |

|---|---|---|---|

| Grain Structure | Directional & Refined | Random & Coarser | Unchanged from Original |

| Material Strength | Highest | Lower | Good, but Wastes Material |

| Fatigue Resistance | Excellent | Good | Varies |

| Material Utilization | High | High | Low (High Scrap) |

Primary Forging Processes for Stainless Steel

There are several forging methods, each suited for different part geometries and volume requirements. The choice of process significantly impacts the final component's properties and cost-effectiveness.

Open-Die Forging

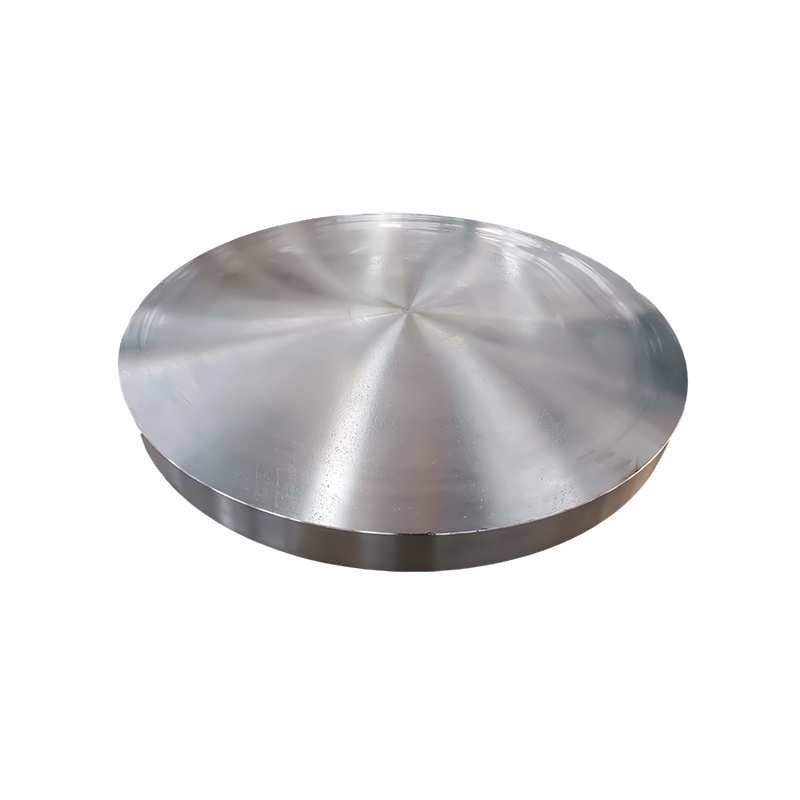

Also known as free forging, this process uses flat or simple-shaped dies. The workpiece is hammered or pressed into shape, allowing for the creation of very large or custom components like large diameter stainless steel forged rings and massive shafts. It offers great flexibility and is ideal for low-volume, high-mix production.

- Typical Products: Large cylinders, shafts, discs, and simple shaped blanks.

- Advantages: Flexibility for large sizes, improved mechanical properties through work hardening.

- Considerations: Requires significant machining allowance to achieve final dimensions.

Closed-Die Forging

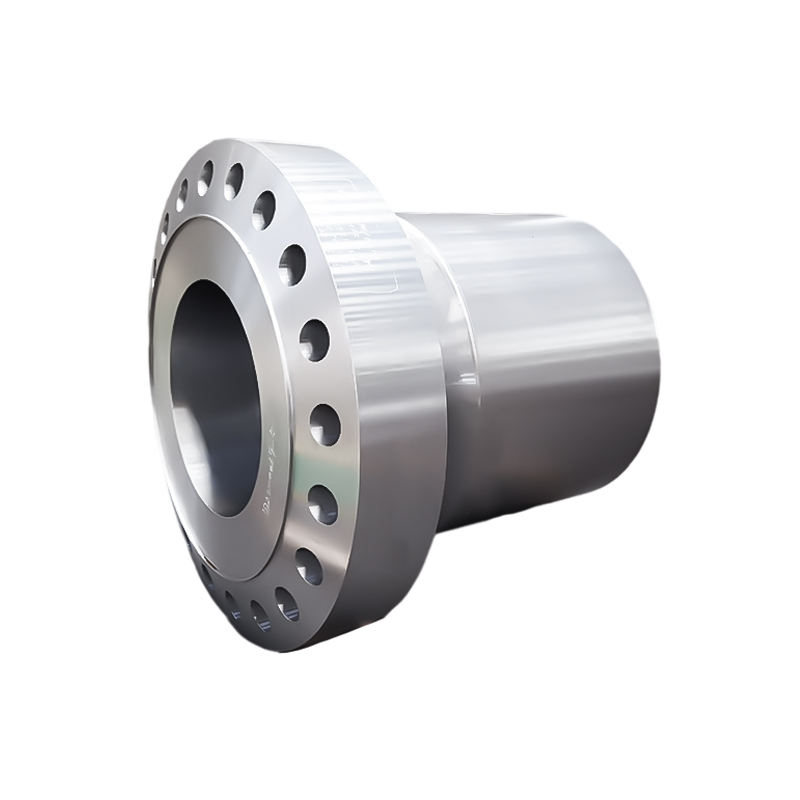

In this method, the heated billet is placed between two dies that contain a pre-cut impression of the desired part. The metal flows to fill the die cavities, producing near-net-shape components with excellent dimensional accuracy. This process is key for producing complex corrosion resistant forged stainless fittings.

- Typical Products: Flanges, fittings, gears, and connecting rods.

- Advantages: High production rates, excellent material utilization, good surface finish.

- Considerations: High initial die cost, best for high-volume runs.

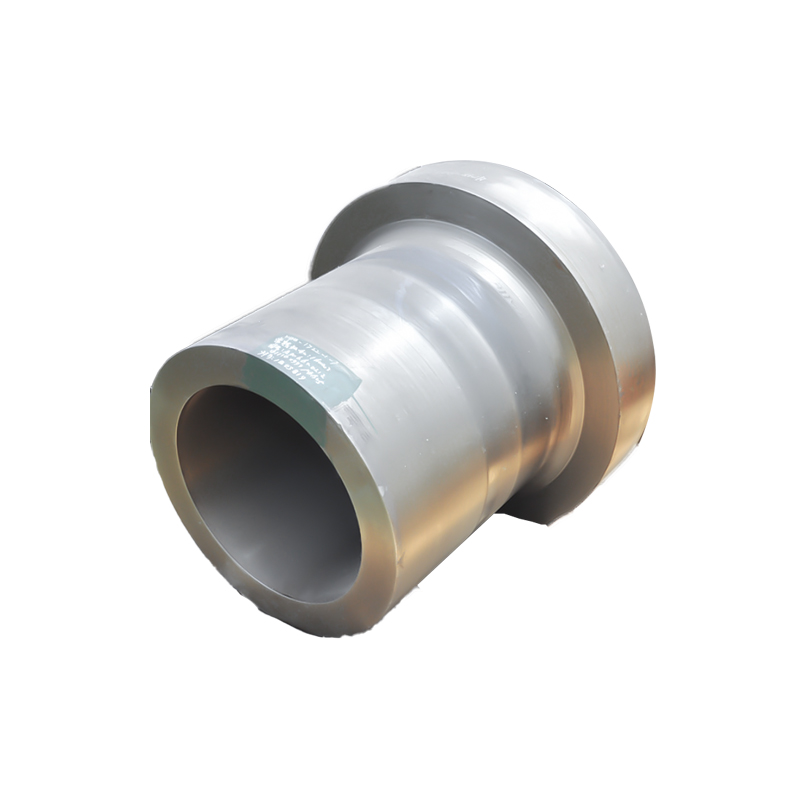

Ring Rolling

Ring rolling is a specialized forging process used to produce seamless rings. A pre-forged donut-shaped piece is rotated under pressure between a main roll and a mandrel, gradually expanding its diameter and refining its cross-section. This is the premier method for creating seamless rolled stainless steel rings used in bearings, flanges, and aerospace components. Maiterio Group, with its three dedicated ring forging lines, exemplifies expertise in this high-precision area.

- Typical Products: Precision rings for turbines, bearings, couplings, and flanges.

- Advantages: Seamless structure, material savings, superior strength circumferential grain flow.

- Considerations: Requires specialized equipment and expertise.

Critical Applications and Industries

The unique combination of strength, corrosion resistance, and reliability makes stainless steel forgings vital across several heavy industries.

Energy Generation (Renewable & Conventional)

In power generation, components face extreme temperatures, pressures, and corrosive environments. Forged stainless steel shafts for turbines are fundamental in both gas turbines and wind turbine gearboxes due to their ability to withstand high torsional and fatigue loads. Similarly, critical valves, casings, and reactor parts in nuclear and fossil fuel plants rely on forgings for safety and longevity [1].

Heavy Machinery & Off-Highway Equipment

Equipment from companies like Caterpillar and Komatsu operates under brutal conditions. Forged stainless components provide the necessary durability. This includes high strength stainless forged components like axle shafts, hydraulic cylinders, and undercarriage parts that resist wear, impact, and corrosion from environmental exposure.

Oil & Gas and Chemical Processing

The extraction and processing industries demand materials that can handle sour gases, high pressures, and corrosive chemicals. Stainless steel forged flanges and valves are standard in pipeline systems, wellhead equipment, and chemical reactors because their forged integrity minimizes the risk of catastrophic failure [2].

Design and Specification Considerations

Selecting the right forging parameters is crucial for performance and cost. Engineers must consider several factors.

Material Grade Selection

Choosing the appropriate stainless steel grade (e.g., 304/304L, 316/316L, 410, 17-4 PH, Duplex) depends on the service environment's corrosion demands, strength requirements, and temperature ranges.

Forging Design for Manufacturability

- Draft Angles & Parting Lines: Essential for part ejection from dies in closed-die forging.

- Fillets and Radii: Sharp corners create stress concentrations and forging defects; generous radii promote metal flow and strength.

- Forging Allowance: Additional material left on the forging for subsequent machining to final dimensions. Modern forging lines, such as those designed by Maiterio Group based on 30 years of user experience, are engineered for smaller allowances, reducing material waste and machining time.

Advantages of Partnering with a Certified Forging Specialist

Producing high-integrity forgings requires more than just equipment; it demands deep process knowledge and rigorous quality systems.

Integrated Quality Assurance

Certifications like ISO 9001 (Quality), 14001 (Environmental), and 45001 (Occupational Health & Safety) form the baseline. A specialist like Maiterio Group integrates quality control at every stage—from sourcing raw material to final machining. Being the largest customer of a top-tier steel mill like Yong Gang ensures not only competitive pricing but also metallurgical quality guaranteed by internal consumption and testing.

Vertical Integration and Whole-Line Solutions

The industry trend is toward vertically integrated suppliers. Maiterio Group's development of steel trading and forging whole-line solutions in 2024 exemplifies this. This integration offers clients:

- Supply Chain Security: Controlled material sourcing from mill to finished part.

- Cost Optimization: Savings from bulk material purchasing and efficient process flow.

- Technical Synergy: Forging engineers who understand material behavior can optimize the entire production line for higher pace and precision.

Technical Expertise and Innovation

Ultimately, the value lies in the team's expertise. Founders and teams with over 30 years of industry leadership bring invaluable knowledge in process design, defect prevention, and applying forgings to solve complex engineering challenges for global giants in energy and machinery.

Frequently Asked Questions (FAQs)

1. What are the main benefits of choosing stainless steel forgings over castings?

Forgings offer a denser grain structure, leading to higher strength, better impact and fatigue resistance, and greater reliability under high stress. They are generally free from the porosity and inclusions that can occur in castings, making them safer for critical applications.

2. Which industries most commonly use large diameter stainless steel forged rings?

These rings are essential in wind and steam turbine construction, aerospace propulsion systems, large-scale bearing assemblies, and as flanges in major pipeline and pressure vessel projects.

3. Why is corrosion resistance important in forged stainless fittings?

In industries like chemical processing, oil & gas, and marine, fittings are exposed to highly corrosive media. Corrosion-resistant forged stainless fittings prevent leaks and failures, ensuring system integrity, safety, and long service life, reducing maintenance costs and downtime.

4. What makes forged stainless steel shafts ideal for turbines?

Turbine shafts must transmit immense torque while withstanding cyclic loads. The forging process aligns the grain flow along the shaft's axis, maximizing its torsional strength and fatigue resistance, which are critical for reliable, continuous operation over decades.

5. When should I specify high strength stainless forged components?

Specify these components when the application involves extreme mechanical loads, high-pressure environments, or significant impact forces, and where corrosion resistance is simultaneously required. Examples include critical parts in heavy machinery, defense equipment, and high-performance automotive or aerospace systems.

Stainless steel forgings represent the pinnacle of metal component manufacturing for demanding applications. From seamless rolled stainless steel rings for renewable energy to high strength stainless forged components for earth-moving machinery, the forging process delivers unmatched performance. Success hinges on partnering with a technically proficient supplier that controls the entire value chain—from premium material sourcing to precision forging and machining. As industries push for greater efficiency and reliability, the role of advanced, certified forging specialists becomes ever more central to engineering success.

References

[1] ASM International. (2023). "Properties and Selection of Stainless Steels in Power Generation." ASM Handbook, Volume 6: Welding, Brazing, and Soldering. (This reference supports the discussion on the use of forged stainless components in turbine and energy applications).

[2] Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill. (This reference is a standard for piping engineering and supports the use of forged flanges and valves in critical service applications).

English

English Español

Español русский

русский