Introduction

In modern industrial manufacturing, stainless steel forgings play a crucial role. They are widely used not only in aerospace, petrochemical, and machinery manufacturing sectors but also in everyday industrial components. Compared to other processing methods, forging improves the mechanical properties of materials and ensures the stability and longevity of the products.

With continuous advancements in manufacturing technology, understanding stainless steel forgings processes, types, applications, advantages, and standards is highly valuable for engineers, designers, and procurement professionals. This article provides a comprehensive overview to help readers fully grasp the value and potential applications of stainless steel forgings.

1. Stainless Steel Forging Process

1.1 Overview of Forging Process

The stainless steel forging process refers to shaping stainless steel billets under applied pressure through plastic deformation to achieve the desired shape and properties. Compared to casting and welding, forging significantly improves the metal's microstructure, reduces internal defects, and enhances strength and toughness.

The key to the forging process lies in controlling temperature, pressure, and deformation rate to ensure uniform grain refinement and meet mechanical performance requirements. According to processing temperature and methods, common forging processes include:

- Hot forging: Conducted above the material's recrystallization temperature, mainly for large stainless steel forgings. Advantages include good plasticity and ease of forming complex shapes; disadvantages are relatively lower dimensional accuracy and the need for post-machining.

- Cold forging: Performed at room temperature or below the recrystallization temperature, suitable for small to medium-sized parts. Provides high surface finish and dimensional accuracy but limited plasticity and requires greater pressure.

- Warm forging: Between hot and cold forging, combining the plasticity of hot forging and the accuracy of cold forging, increasingly applied in high-end manufacturing.

1.2 Forging Equipment and Tools

Modern stainless steel forging typically uses the following equipment:

- Hammer: Applies impact force through free fall or mechanical impact, suitable for small to medium-sized forgings.

- Press: Forms parts with uniform pressure, suitable for complex shapes and large forgings.

- Die forging machines: Multi-directionally compress billets using molds for high precision, ideal for mass production.

Tooling such as dies, punches, heating furnaces, and cooling equipment are essential for ensuring forging quality. Die materials must have high wear resistance and thermal strength to withstand repeated impacts during high-temperature forging.

1.3 Effect of Forging Process on Performance

The performance of stainless steel forgings is mainly affected by the following factors:

- Temperature control: Excessive temperature causes grain coarsening and reduces strength; insufficient temperature increases deformation resistance and may cause cracks.

- Deformation rate: Too fast may cause local stress concentration and defects; too slow reduces production efficiency.

- Amount of plastic deformation: Proper deformation refines grains and enhances mechanical properties.

By scientifically controlling these factors, stainless steel forgings can achieve high strength while maintaining excellent toughness, fatigue resistance, and corrosion resistance.

1.4 Heat Treatment and Surface Treatment

Forged stainless steel parts usually require heat and surface treatment to further optimize performance:

- Annealing: Eliminates internal stress and improves toughness and plasticity.

- Quenching and tempering: Increases hardness and wear resistance, suitable for high-load parts.

- Surface polishing and plating: Enhances appearance and corrosion resistance, widely used in chemical and food industries.

2. Types of Stainless Steel Forgings

2.1 Classification by Shape

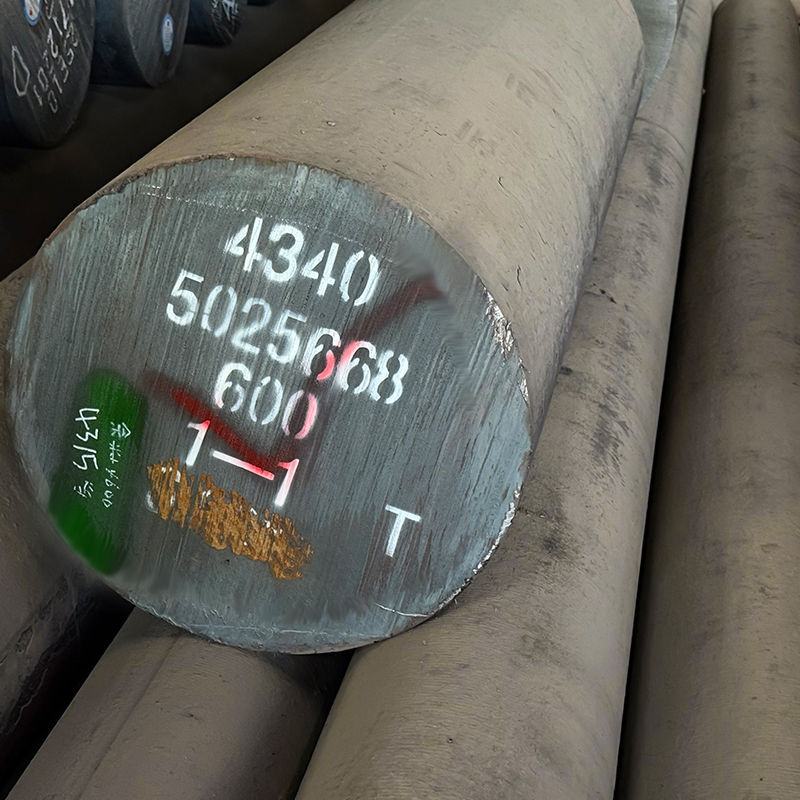

- Round Forgings: Common cylindrical, disc, or shaft parts such as shafts, discs, and gears. Advantages include uniform stress distribution, suitable for rotating components.

- Square/Block Forgings: Used in mechanical structural parts such as connection plates and supports, easy to machine into final shapes.

- Complex/Shaped Forgings: Custom-shaped parts like pump bodies, valve bodies, and aerospace components. They are difficult to machine but directly meet engineering requirements.

2.2 Classification by Application

- Structural forgings: Ship frames, machinery frames, emphasizing strength and toughness.

- High-temperature and high-pressure forgings: Boiler flanges, pressure vessel components, requiring high-temperature resistance and stress corrosion resistance.

- Corrosion-resistant forgings: Chemical valves, pumps, requiring long-term stability in acidic and alkaline environments.

2.3 Comparison with Other Processing Methods

- Compared with casting: Forgings are denser, have better mechanical properties, and longer fatigue life.

- Compared with welding: Forgings avoid stress concentration and corrosion risks associated with welds, more suitable for critical load-bearing parts.

3. Stainless Steel Forging Applications

3.1 Aerospace

In aerospace, materials require extremely high strength, toughness, and fatigue life. stainless steel forgings are commonly used for:

- Aircraft landing gear

- Turbine shafts

- High-pressure fuel lines

The forging process ensures uniform internal structure, maintaining stable performance under high stress and temperature.

3.2 Petrochemical Industry

In petrochemical equipment, forgings often endure high pressure, high temperature, and corrosive environments:

- Valves, pump bodies, flanges

- Pressure vessels and pipeline connectors

Stainless steel forgings enhance safety and durability in these applications.

3.3 Machinery Manufacturing

In machinery, forgings improve load-bearing capacity and extend service life, including:

- Gears, shafts

- Hydraulic machinery components

- Core components of industrial transmission systems

Forging ensures parts can operate long-term under high load without fatigue failure.

4. Stainless Steel Forging Advantages

4.1 High Strength and Toughness

The forging process refines and evenly distributes grains, greatly enhancing material strength and toughness:

- High strength: Strong load-bearing capacity for high-stress components.

- Good toughness: Resistant to impact and vibration, extending service life.

4.2 Excellent Corrosion Resistance

Stainless steel inherently has good corrosion resistance, and forging further increases density, reducing pores and defects:

- Chemical equipment: resistant to acid and alkali, ensuring long-term safe operation.

- Marine engineering: maintains performance in saltwater environments, preventing rust.

4.3 High Fatigue Life

Forging optimizes grain alignment and internal structure, reducing stress concentration points and significantly increasing fatigue life:

- Rotating components (shafts, gears) are more durable.

- High-pressure pipelines and valves remain stable under long-term heavy loads.

4.4 Machining and Forming Advantages

- Accurate dimensions: Die forging produces near-final shapes, reducing machining requirements.

- Complex structures achievable: Custom or large parts meet design requirements directly.

- High material utilization: Less cutting waste, improved cost efficiency.

4.5 Comparison with Other Methods

| Processing Method | Strength | Toughness | Fatigue Life | Forming Complexity | Corrosion Resistance |

|---|---|---|---|---|---|

| Forging | High | High | High | High | High |

| Casting | Medium | Medium | Medium | Medium | Medium |

| Welding | Medium | Low | Medium-Low | Medium | Medium-Low |

5. Stainless Steel Forging Standards

5.1 International Standards

- ASTM (American Society for Testing and Materials): e.g., ASTM A182 for high-pressure boiler and valve stainless steel forgings, specifying chemical composition, mechanical properties, and testing methods.

- ISO (International Organization for Standardization): Applicable to aerospace and machinery forgings, providing unified inspection and acceptance standards for international trade.

5.2 Domestic Standards

- GB/T series: GB/T 1220, GB/T 1221, covering dimensions and performance requirements for various stainless steel forgings, widely used in petrochemical, machinery, and high-temperature equipment industries.

5.3 Role of Standards

- Ensure consistent quality: Different suppliers produce forgings meeting the same technical requirements.

- Ensure safety: Standardized forgings reduce risk in high-pressure, high-temperature, and corrosive environments.

- Facilitate engineering design: Designers can rely on standard parameters for reliable calculations.

6. Future Development Trends

6.1 High-precision and Lightweight Forging

Aerospace and new energy vehicles demand higher strength-to-weight ratios. Combining high-precision forging with lightweight design reduces energy consumption and improves performance.

6.2 Intelligent Manufacturing

CNC forging machines and intelligent monitoring systems allow traceable and optimized forging processes. Big data and AI can optimize forging parameters for efficient and stable production.

6.3 Development of New Materials and Alloys

High-strength, high-temperature, and corrosion-resistant new stainless steel alloys continue to emerge. Combined with forging processes, they meet more demanding engineering requirements, such as deep-sea, aerospace, and high-temperature nuclear fields.

7. Conclusion

In summary, stainless steel forgings are indispensable key materials in modern industrial manufacturing. Their core advantages include:

- High strength and toughness for critical load-bearing components.

- Excellent corrosion resistance for harsh environments.

- High fatigue life extending service life.

- Machining and forming advantages for material utilization and production efficiency.

- Standardization ensuring safety and consistency.

Whether in aerospace, petrochemical, or machinery manufacturing, mastering the stainless steel forging process, understanding types of stainless steel forgings, identifying stainless steel forging applications, leveraging stainless steel forging advantages, and strictly following stainless steel forging standards are key to achieving high-quality production and long-lasting applications.

With the development of intelligent manufacturing, material innovation, and precision forging technologies, stainless steel forgings will play an even greater role in high-end industries. For engineers, designers, and manufacturers, in-depth understanding of this field is essential for enhancing competitiveness and technical expertise.

English

English Español

Español русский

русский