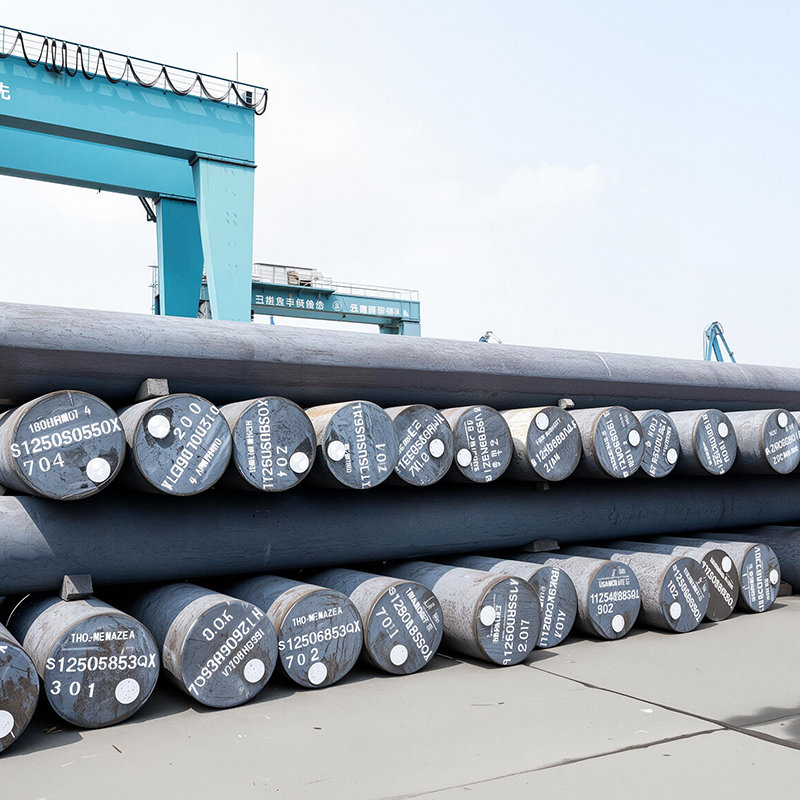

17CrNiMo6/18CrNiMo7-6 alloy steel

17CrNiMo6 and 18CrNiMo7-6 are high-grade case hardening steels known for their excellent core toughness, high surface hardness, and superior fatigue resistance. These nickel-chromium-molybdenum alloy steels are widely used in gear manufacturing and heavy-duty mechanical components that demand both wear resistance and high strength.

- Benefits

- Heat Treatment

- Applications

- Availability

- Parameter

English

English Español

Español русский

русский