In the realm of high-stress industrial applications, Carbon Steel Forgings stand as the gold standard for structural integrity and mechanical reliability. Unlike casting or machining from bar stock, the forging process physically deforms the metal to align its internal grain flow, resulting in superior directional properties. For engineers and procurement specialists, selecting the right grade of Carbon Steel Forgings is not just about chemical composition; it involves a deep understanding of thermal processing, plastic deformation, and metallurgical transformation. This guide delves into the technical specifications and manufacturing nuances that define high-performance forged components.

1. Understanding the Metallurgy of Carbon Steel Forgings

The performance of industrial carbon steel forgings is dictated by the carbon content and the subsequent heat treatment. Low carbon steels (0.05% to 0.25% carbon) offer excellent weldability and ductility, while medium carbon steels (0.30% to 0.50%) provide a balanced profile of strength and toughness. When considering carbon steel forgings for oil and gas industry applications, the ability to withstand high pressures and corrosive environments is paramount. Engineers often specify normalized or quenched and tempered conditions to ensure the microstructure is homogeneous, eliminating internal voids that are common in cast alternatives.

Comparison: Carbon Content and Mechanical Performance

As carbon content increases, the tensile strength and hardness of the forging improve significantly, though this comes at the cost of reduced ductility and increased difficulty in welding.

| Carbon Grade | Typical Tensile Strength (MPa) | Ductility (Elongation %) | Common Application |

| Low Carbon (AISI 1018) | 440 - 500 | 20 - 30 | Bushings, Brackets, General Fabrication |

| Medium Carbon (AISI 1045) | 570 - 700 | 12 - 20 | Gears, Shafts, Axles, Crankshafts |

| High Carbon (AISI 1080) | 800 - 1000 | 5 - 10 | Cutting Tools, High-Strength Springs |

2. Open Die vs. Closed Die: Choosing the Right Forging Process

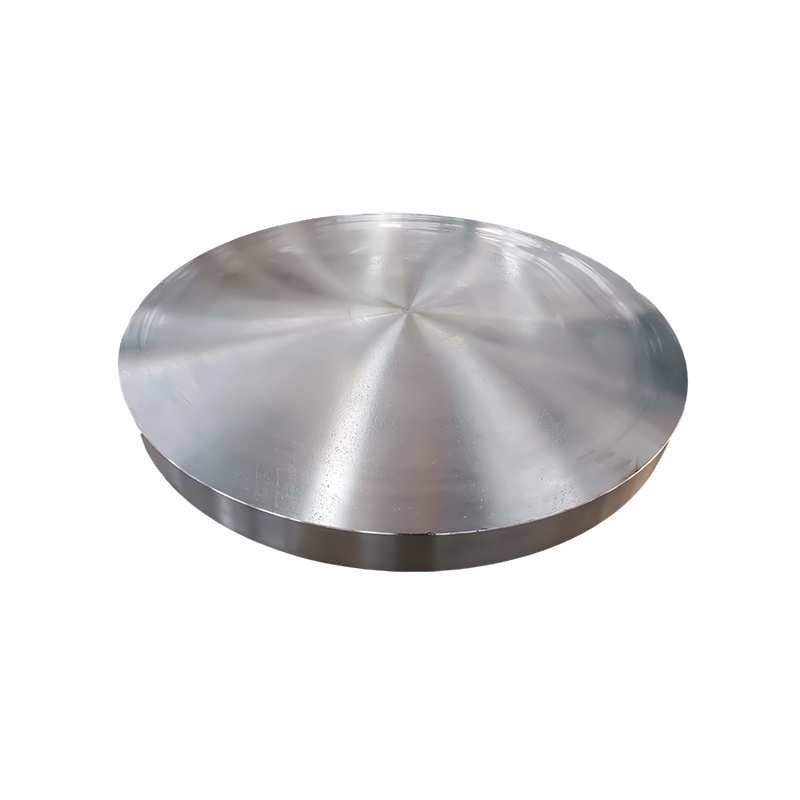

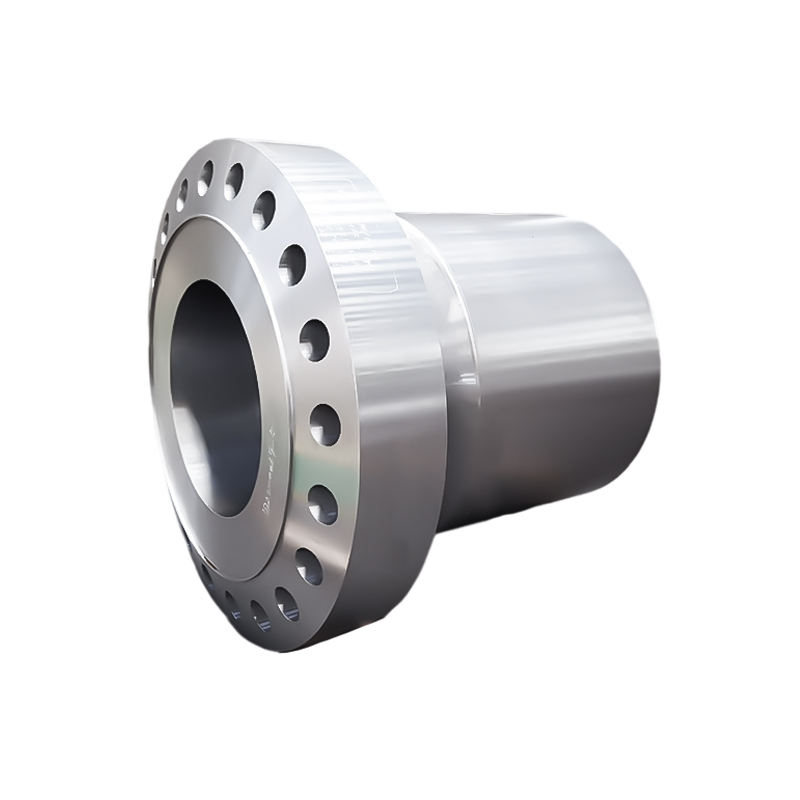

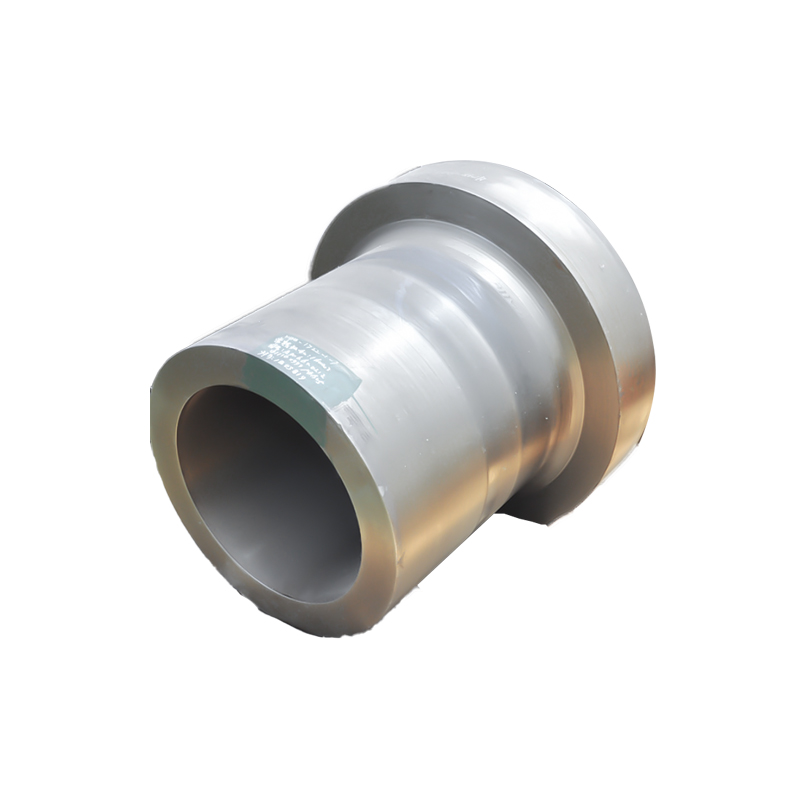

The choice between forging methods depends on the complexity of the part and the required production volume. Custom carbon steel forgings are frequently produced via open die forging for large-scale components like shafts and rings. Conversely, closed die forging (or impression die forging) is utilized for high-precision, high-volume parts. While open die forging offers flexibility in size without the need for expensive custom tooling, closed die forging provides superior dimensional tolerances and better material utilization for complex geometries.

Comparison: Forging Methodology Efficiency

Open die forging is characterized by its lower tooling costs and suitability for massive parts, whereas closed die forging excels in detail and consistency for smaller components.

| Feature | Open Die Forging | Closed Die Forging |

| Component Complexity | Simple (Blocks, Cylinders) | Complex (Gears, Connectors) |

| Tooling Cost | Low (Universal Dies) | High (Custom Die Sets) |

| Weight Range | Up to 100+ Tons | Typically under 500 kg |

| Grain Flow Control | Moderate | Superior / Precise |

3. Critical Standards and Quality Assurance: ASTM and Beyond

Adherence to international standards is non-negotiable for safety-critical components. The ASTM A105 carbon steel forgings standard is the most prevalent for piping applications, covering forged carbon steel components for ambient and higher-temperature service in pressure systems. For structural and general engineering, the ASTM A668 forging specifications provide a framework for different classes of carbon and alloy steel forgings. Understanding these carbon steel forging standards and grades allows engineers to match the material's yield strength and impact toughness to the specific environmental loads the component will face.

Key Quality Control Protocols:

- Ultrasonic Testing (UT): To detect internal discontinuities or inclusions.

- Magnetic Particle Inspection (MPI): To identify surface or near-surface cracks.

- Charpy V-Notch Impact Test: To verify the material's toughness at low temperatures.

- Hardness Testing (Brinell/Rockwell): To ensure consistent thermal processing.

4. Enhancing Durability: Post-Forging Operations

Even the highest quality Carbon Steel Forgings require secondary processing to achieve final design requirements. Machining of carbon steel forgings is often necessary to reach precise tolerances on mating surfaces. Furthermore, because carbon steel is susceptible to oxidation, protective coatings or platings are frequently applied. When comparing forged vs cast carbon steel properties, the forged version consistently exhibits 26% higher tensile strength and a 37% increase in fatigue life, making it the superior choice for dynamic loading environments.

Comparison: Forged vs. Cast Mechanical Integrity

Forging eliminates internal gas pockets and shrinkage that are inherent in casting, leading to a much higher density and more predictable failure modes.

| Property | Cast Carbon Steel | Forged Carbon Steel |

| Internal Porosity | Common (Needs NDT) | Virtually Non-Existent |

| Fatigue Resistance | Moderate | Excellent (Aligned Grain) |

| Response to Heat Treatment | Variable | Highly Predictable |

5. Sustainable Sourcing and Carbon Neutrality in Steel Production

As the industry moves toward "Green Steel," the forging process standards are evolving to include energy-efficient induction heating and the use of recycled scrap as raw material. Selecting a carbon steel forging manufacturer in China or globally that utilizes modern hydraulic presses with energy recovery systems can significantly reduce the carbon footprint of a project without compromising the structural performance of the industrial forged steel components.

Frequently Asked Questions (FAQ)

1. What is the main advantage of Carbon Steel Forgings over machined bar stock?

The primary advantage is the continuous grain flow. Machining "cuts" through the metal's natural grain, creating weak points. Forging deforms the grain to follow the contour of the part, providing superior strength-to-weight ratios and fatigue resistance.

2. Why are ASTM A105 carbon steel forgings so common in the valve industry?

ASTM A105 is specifically designed for high-pressure, high-temperature piping components. It offers predictable weldability and excellent strength at ambient temperatures, making it ideal for flanges, valves, and fittings.

3. How do custom carbon steel forgings handle low-temperature environments?

Standard carbon steel can become brittle at low temperatures. To combat this, forgings are often treated with a normalization process or specific alloying elements (like manganese) to improve notch toughness, verified through Charpy impact testing.

4. What is the maximum size for industrial carbon steel forgings?

Using open die forging techniques, industrial components like generator rotors or ship propulsion shafts can exceed 100 tons in weight and 20 meters in length.

5. Is machining of carbon steel forgings more difficult than machining castings?

Generally, no. Forgings are more homogeneous and lack the hard spots or sand inclusions often found in castings, which actually helps extend tool life during the machining process.

Industry References

- ASTM A105 / A105M - Standard Specification for Carbon Steel Forgings for Piping Applications.

- Forging Industry Association (FIA) - Fundamentals of Forging Technology.

- ISO 683-1: Heat-treatable steels, alloy steels and free-cutting steels.

- ASM International - Handbook of Metalworking: Bulk Forming.

English

English Español

Español русский

русский