Introduction

The global shift toward renewable energy makes wind power a key player in replacing fossil fuels. Wind turbines, essential for generating electricity, rely heavily on high-quality, durable components to operate efficiently. Wind power forgings, precision-engineered metal parts created through compressive force, enhance turbine strength and performance. These forged components are critical in ensuring turbines withstand extreme conditions such as high winds, temperature changes, and mechanical stress. With turbines growing larger and more efficient, the role of wind power forgings in advancing renewable energy becomes increasingly vital.

Understanding Wind Power Forgings

Wind power forgings are essential for constructing wind turbines, designed to meet the high demands of wind energy production where strength and reliability are crucial. Forging is a process where metal is shaped under compressive forces, improving its strength and uniformity by enhancing its internal grain structure.

In wind turbines, forged parts like shafts, rotor hubs, and gearboxes need to be strong, corrosion-resistant, and able to withstand mechanical stress. Forging offers advantages over casting, as it produces components that are stronger and more reliable, essential for turbines that endure constant wind and mechanical loads. The quality of forged components directly impacts the efficiency and longevity of wind turbines, making them vital for the success of wind energy.

Common Forging Materials Used in Wind Power Applications

| Forging Type | Material Used | Key Characteristics | Applications in Wind Power |

|---|---|---|---|

| Steel Forgings | Carbon Steel | High strength, durability | Gearboxes, turbine shafts |

| Alloy Forgings | Stainless Steel | Corrosion resistance | Rotor hubs, bearings |

| Titanium Forgings | Titanium Alloys | Lightweight, high strength | Blades, structural supports |

Key Components in Wind Power Forgings

-

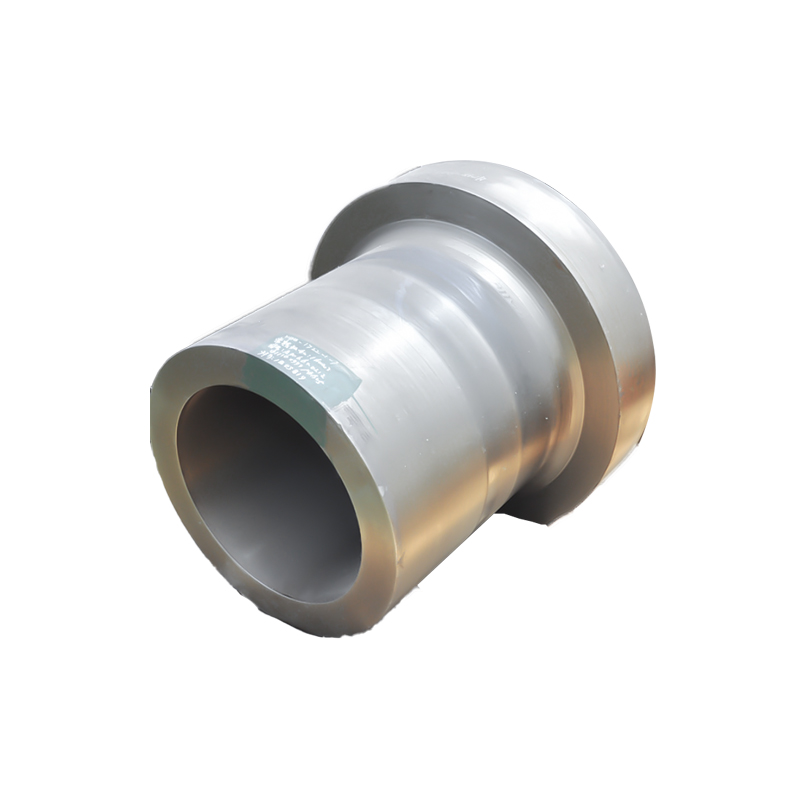

Turbine Shafts:

- Responsible for transmitting mechanical energy from the blades to the rest of the system.

- Forged turbine shafts are designed to handle high torque loads.

- Must withstand harsh wind conditions and resist deformation, fatigue, and wear over time.

-

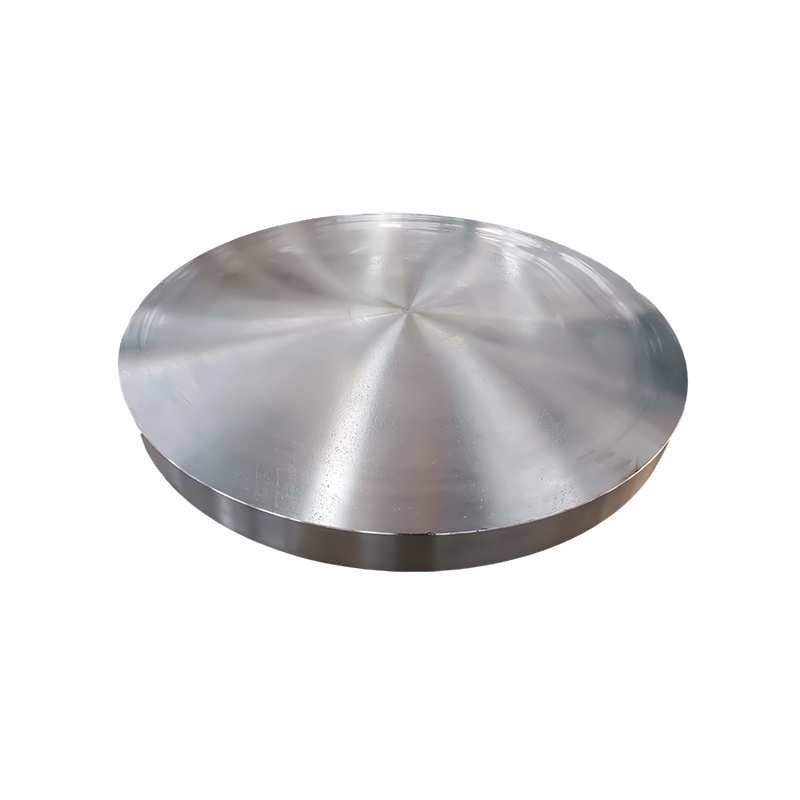

Rotor Hubs:

- Connect the turbine blades to the main shaft.

- Must be strong enough to endure stresses from wind pressure and rotational forces generated by the blades.

- Precision and strength of forged rotor hubs are essential for smooth and efficient turbine operation.

-

Gearboxes:

- Convert low-speed rotation of turbine blades into high-speed rotation for electricity generation.

- Forged components are crucial for withstanding high mechanical stresses.

- Must maintain structural integrity under extreme forces for long periods of operation.

-

Importance of Forged Components:

- The reliance on forged parts for turbine shafts, rotor hubs, and gearboxes underscores the need for high-quality materials and precise manufacturing.

- Properly forged components are vital for the longevity and efficiency of wind turbines.

- Without high-quality forgings, the performance of wind turbines would be significantly compromised.

Advantages of Forged Components in Wind Power

-

Enhanced Strength:

Forged components offer significantly greater strength compared to other manufacturing methods. The forging process, which involves shaping metal under high pressure, results in a denser and more uniform grain structure. This makes forged parts more resistant to the stresses and strains they experience during operation. For wind turbines, which are exposed to constant mechanical loads from wind forces, this increased strength ensures that critical components such as turbine shafts, rotor hubs, and gearboxes maintain their integrity and function reliably over time. -

Superior Resistance to Fatigue and Wear:

Forged components are highly resistant to fatigue and wear, crucial for the performance of wind turbines. Wind turbines operate in harsh environments where parts are subject to continuous motion and external forces, leading to material fatigue and potential failure. The uniform grain structure of forged materials, combined with their high strength, allows them to withstand repeated stresses, extending the operational life of the turbine and reducing the need for costly maintenance and replacements. -

Cost-Effectiveness in Large-Scale Manufacturing:

Forging is a cost-effective method for producing components at scale. While the initial investment in forging technology may be high, the process is highly efficient, leading to lower cost per unit for large quantities of parts. This is particularly important in the wind power industry, where turbines consist of numerous parts requiring precision and durability. Forged components are typically more cost-effective than cast or fabricated parts, especially when considering long-term savings from increased reliability and fewer replacements. -

Superior Material Properties Compared to Casting:

The forging process offers superior material properties compared to casting. Casting, which involves pouring molten metal into molds, can result in internal defects and a less uniform grain structure. These defects can compromise component performance, particularly under high-stress conditions like those encountered in wind turbines. In contrast, forging eliminates these internal defects by compressing the metal during the manufacturing process, producing a more resilient and reliable part.

Applications of Wind Power Forgings

-

Turbine Shafts:

- Forged turbine shafts transmit mechanical power from the turbine blades to the generator.

- These shafts must endure extreme stress from the rotational forces of the blades and continuous pressure from wind currents.

- The durability of the shafts is crucial for turbine performance; failure can cause catastrophic damage and significant loss in energy production.

-

Rotor Hubs:

- Rotor hubs house the turbine blades and connect them to the main shaft.

- They must withstand immense forces, including wind pressure and torque generated during rotation.

- Forged rotor hubs offer the necessary strength and precision to prevent deformation and failure under high-stress conditions.

-

Gearboxes:

- Gearboxes rely on high-quality forged components, especially gears and shafts, to convert rotational energy into electrical power.

- Forged components in the gearbox ensure efficient power transmission and reduce the risk of wear and tear over time.

- The strength and reliability of forged parts are essential to the longevity of the gearbox, which operates under high stress and varying speeds.

Forged Components in Wind Power Turbines

| Component | Forging Application | Material Used | Key Characteristics | Performance Requirements |

|---|---|---|---|---|

| Turbine Shaft | Transmitting mechanical power | Carbon Steel | High strength, durability | High torque, fatigue resistance |

| Rotor Hub | Connecting blades to shaft | Stainless Steel | Corrosion resistance, strength | Durability under wind pressure and torque |

| Gearbox Shafts | Power transmission | Alloy Steel | Wear resistance, strength | High load-bearing capacity |

| Bearings | Reducing friction | Stainless Steel | Corrosion resistance, smooth operation | Longevity, high-speed tolerance |

How to Choose Wind Power Forgings

-

Strength Considerations:

- Wind power forgings must withstand significant mechanical stresses, including high torque loads from the turbine blades and dynamic forces from wind gusts.

- Materials like carbon steel and titanium alloys are often chosen due to their superior strength-to-weight ratios, ensuring the components can handle stresses without compromising performance.

-

Corrosion Resistance:

- Especially important for offshore wind turbines exposed to saltwater and harsh marine environments.

- Stainless steel and specialized alloys are frequently used because of their exceptional resistance to corrosion and wear.

- These materials help extend the turbine’s lifespan and reduce long-term maintenance costs.

-

Weight Considerations:

- Lighter materials are crucial for components like turbine blades and hubs to ensure efficient energy conversion and reduce mechanical load.

- Titanium is ideal for these parts due to its lightweight nature.

- Despite being lightweight, these materials must still provide the necessary strength and fatigue resistance for long-term reliability.

-

Cost:

- Titanium alloys offer excellent performance but come with a higher cost.

- A balance must be struck between cost and performance to ensure the economic feasibility of turbine production and operation.

- Steel forgings are often the most cost-effective option, providing good strength and durability at a lower cost than more specialized materials.

The Global Market for Wind Power Forgings

As the wind power industry expands globally, the demand for high-quality forged components is increasing. Wind power forgings play a crucial role in the production of large-scale turbines, and their market is driven by the growing need for more efficient and durable turbines that can operate in diverse and challenging environments. The global market for wind power forgings is closely tied to the overall growth of renewable energy, as governments, industries, and consumers alike are pushing for a shift toward cleaner energy sources.

Wind Power Forgings Maintenance and Care

Maintaining the integrity and performance of wind turbines is critical to ensuring their long-term reliability and minimizing costly downtime. Wind power forgings, which are integral to the structure and operation of turbines, require proper care and regular maintenance to ensure they perform optimally throughout their lifespan. Here’s an overview of essential maintenance practices for wind power forgings:

-

Routine Inspection and Monitoring

Regular inspections are key to identifying early signs of wear, fatigue, or damage to forged components. Turbine shafts, rotor hubs, and gearboxes must be visually and technically assessed to detect any cracks, corrosion, or signs of fatigue. Non-destructive testing (NDT) techniques, such as ultrasonic testing and X-ray inspection, can help detect internal defects that might not be visible to the naked eye. Early detection allows for timely interventions, preventing catastrophic failures. -

Lubrication and Friction Control

Proper lubrication is essential for the longevity of forged components in gearboxes and other moving parts. The continuous movement of turbine blades and mechanical systems generates friction, which can lead to wear over time. Regular maintenance of lubrication systems, using the right type and amount of lubricant, helps minimize friction, reduces wear, and extends the life of forged parts. Additionally, the removal of contaminants from lubrication systems is crucial to maintaining component efficiency. -

Corrosion Protection

Corrosion is a significant concern for wind power forgings, particularly in offshore turbines where exposure to saltwater accelerates the degradation of materials. Protective coatings, such as galvanization or corrosion-resistant alloys, are often applied to forged components to protect them from the elements. Regular checks for corrosion on components like rotor hubs and bearings should be conducted, and any signs of damage should be addressed promptly to prevent further degradation. -

Replacement and Repair of Worn Components

Despite regular maintenance, some forged components will inevitably experience wear and tear due to the extreme operational conditions wind turbines face. It is essential to have a proactive approach to component replacement and repair. When components such as turbine shafts or gearboxes are found to be beyond repair, timely replacement with high-quality forged parts ensures that the turbine continues to operate at peak efficiency. -

Ensuring Structural Integrity

Over time, the constant mechanical stresses placed on forged components can affect their structural integrity. It’s crucial to monitor the performance of key structural parts, including the turbine tower and foundation, to ensure that the forged components are properly supporting the load. Regular maintenance to reinforce or replace structural elements when necessary helps avoid costly operational failures.

Conclusion

Wind power forgings play an indispensable role in the renewable energy sector. As the demand for wind energy grows, the importance of high-quality forged components continues to rise. These components provide the strength, durability, and precision needed to support the advanced technologies in modern wind turbines.

FAQ

1.What are wind power forgings, and why are they important?

Wind power forgings are precision-engineered components made from metal that are essential for the construction and performance of wind turbines. These parts provide the strength, durability, and reliability necessary for turbines to operate efficiently in harsh environments.

2.How do forged components improve the performance of wind turbines?

Forged components enhance the strength and durability of key turbine parts, such as shafts, rotor hubs, and gearboxes. This leads to improved performance, greater efficiency, and a longer operational lifespan.

3.What materials are commonly used in wind power forgings?

Common materials used for wind power forgings include carbon steel, stainless steel, titanium alloys, and other advanced alloys designed to withstand high stress, corrosion, and fatigue.

4.How does forging compare to casting in wind power applications?

Forging produces stronger, more reliable components by shaping metal under high pressure, eliminating internal defects. In contrast, casting can result in imperfections that may compromise the strength and performance of components.

English

English Español

Español русский

русский