In the demanding world of industrial manufacturing, the quality of a component's formation is paramount to its performance and longevity. This is especially true for pelleting dies forging, a specialized process critical for producing durable, high-precision dies used in pellet mills across industries like biomass, feed, and pharmaceuticals. Forging transforms metal under immense pressure, creating a superior grain structure compared to casting or machining from bar stock. This guide delves deep into the intricacies of pelleting dies forging, exploring its methods, advantages, and why it's the preferred choice for heavy-duty applications. As a leader in advanced forging solutions, Maiterio Group combines over 30 years of industry expertise with state-of-the-art facilities to deliver forged components that meet the highest global standards, including for terminal customers in energy and heavy machinery sectors.

Understanding Pelleting Dies and the Forging Imperative

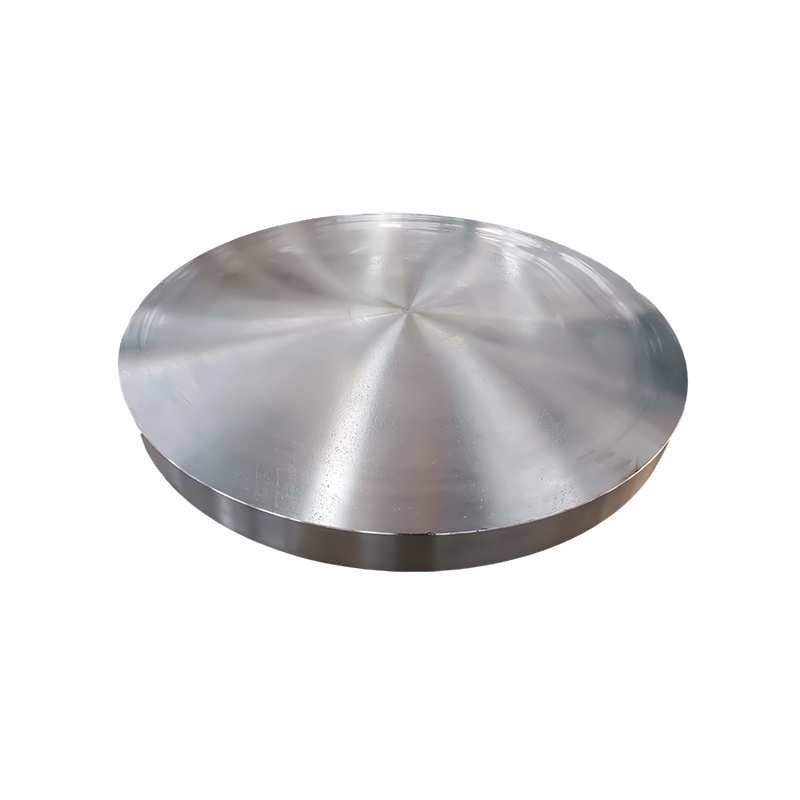

Pelleting dies are cylindrical metal parts with drilled holes through which material is compressed to form pellets. They endure extreme cyclic pressure, abrasion, and heat. Forging is not merely an option but a necessity for high-performance dies, as it fundamentally enhances the metal's internal integrity.

Why Forging Surpasses Alternative Methods

The choice of manufacturing method for pelleting dies significantly impacts their service life and reliability. Forging offers distinct structural advantages over other processes.

- Forged vs. Cast Dies: Forging produces a continuous grain flow that follows the die's contour, eliminating the porosity, shrinkage cavities, and inconsistent grain structure inherent in casting. This results in higher density and isotropic strength.

- Forged vs. Machined-from-Bar Dies: While machining from a solid bar is common, the original bar's grain structure is not optimized for the radial stresses a die experiences. Forging refines and redirects the grain flow, enhancing fatigue resistance.

The following table summarizes the key differences:

| Property | Forged Pelleting Die | Cast Pelleting Die | Machined-from-Bar Die |

|---|---|---|---|

| Grain Structure | Refined, directional flow | Coarse, random | Unchanged from original bar |

| Density & Porosity | High density, no porosity | Potential for porosity and cavities | Dependent on bar quality |

| Fatigue Strength | Exceptionally High | Moderate to Low | High (but not optimized) |

| Impact Resistance | Superior | Lower | Good |

| Life Expectancy | Longest | Shortest | Moderate |

The Pelleting Dies Forging Process: A Step-by-Step Breakdown

Producing a superior forged pelleting die is a meticulous multi-stage process that ensures optimal material properties and dimensional accuracy.

1. Material Selection and Pre-forging Preparation

Alloy Steel Choices

- Common grades include chromium-alloy steels (e.g., DIN 1.2379, 1.2842) known for high wear resistance and through-hardening capability.

- Selection is based on required hardness, toughness, and corrosion resistance for the specific pelletized material (e.g., wood, feed, chemicals).

Billet Heating

- Precise heating in a furnace to a specific forging temperature (typically 1100-1250°C).

- Uniform heating is critical to prevent internal stresses and ensure consistent forgeability.

2. The Core Forging Operation

This is where the magic happens. Heated billets are shaped using open-die or closed-die forging presses.

- Open-Die Forging: Ideal for larger, simpler die blanks. The workpiece is mechanically manipulated between flat or shaped dies. Maiterio Group's expertise in open-die forging allows for precise control over the metal's grain structure.

- Closed-Die (Impression) Forging: The heated metal is forced into a die cavity that closely resembles the final shape of the die blank. This method is excellent for complex geometries and offers excellent material yield.

Our in-house designed forging lines at Maiterio Group enable smaller forging allowances and higher production pace, reducing material waste and cost while maintaining quality.

3. Post-Forging Treatments

Controlled Cooling (Normalizing)

- The forged die blank is cooled under controlled conditions to refine the grain structure homogenized by forging and relieve internal stresses.

Rough Machining

- Excess material (scale, flash) is removed, and the blank is shaped close to final dimensions prior to heat treatment.

Heat Treatment (Hardening & Tempering)

- The most critical step for performance. The die is hardened to achieve high surface hardness (often 58-64 HRC) and then tempered to regain necessary toughness and reduce brittleness.

Precision Finishing

- Final CNC machining achieves exact tolerances. Drilling of precision pellet holes is performed using advanced deep-hole drilling techniques to ensure smooth, consistent bore surfaces.

Optimizing heat treatment for forged pelleting dies

The correct heat treatment protocol is what unlocks the full potential of the forged microstructure. It directly determines the die's surface hardness, core toughness, and resistance to cracking.

- Process Control: Precise temperature control during austenitizing, quenching, and tempering is non-negotiable. Even slight deviations can lead to soft spots or excessive brittleness.

- Tailored Protocols: The treatment must be tailored to the specific steel alloy and the intended application of the die. A die for abrasive biomass requires a different balance than one for animal feed.

Selecting the Best alloy steel for pelleting die forging

Not all alloy steels are created equal. The choice impacts wear life, breakage resistance, and overall cost-effectiveness. For instance, high-chromion cold work tool steels offer excellent wear resistance but may require more careful heat treatment to avoid cracking compared to some hot-work steels[1].

| Steel Type | Key Characteristics | Typical Applications |

|---|---|---|

| Chromium-based Cold Work Steel (e.g., 1.2379) | High wear resistance, good through-hardening | Standard feed pelleting, abrasive materials |

| Tungsten-Molybdenum High-Speed Steel | Exceptional red-hardness, high wear resistance | High-temperature pelleting, demanding applications |

| Nickel-Chromium Alloy Steel | High toughness and impact resistance | Large-diameter dies, high-pressure applications |

Ensuring Quality with pelleting die forging quality control standards

Adherence to stringent quality control standards like ISO 9001 is fundamental. This involves rigorous checks at every stage:

- Material Certification: Verification of steel grade and purity from the mill.

- In-Process Inspection: Dimensional checks during forging and machining.

- Final Testing: Hardness testing across multiple points, ultrasonic testing for internal flaws, and precise dimensional verification.

Maximizing Value: cost analysis of forged vs cast pelleting dies

While the initial unit cost of a forged die is higher than a cast one, the Total Cost of Ownership (TCO) is often lower. The cost analysis of forged vs cast pelleting dies must consider:

- Longer service life (2-3x or more) of forged dies.

- Reduced downtime for die changes.

- Consistent pellet quality, reducing waste and improving product value.

Planning for the Future: pelleting die forging machine setup and maintenance

A reliable forging operation depends on proper pelleting die forging machine setup and maintenance. This includes regular inspection of dies, hydraulic systems, and heating elements to ensure consistent forging temperature and pressure. As designers and long-term users of forging lines, Maiterio Group understands the intricacies of optimizing this setup for pelleting die production.

Why Partner with a Specialist Forging Manufacturer like Maiterio Group?

The complexity of pelleting dies forging demands a partner with deep vertical integration and expertise.

Integrated Production and Material Advantage

Our unique position as the largest customer of a top-tier alloy steel mill guarantees not only the most competitive steel prices but also stringent quality control from the very origin of the material. Our internal consumption allows us to enforce specifications that guarantee forgeability and final performance.

Engineering Expertise and Process Innovation

Our founding team brings over 30 years of forging leadership. This experience is directly applied in our self-designed forging lines, which achieve smaller forging allowances—meaning less material waste and lower machining costs for our clients—and a higher, more consistent production pace.

Commitment to Global Standards

Holding ISO 9001 (Quality), 14001 (Environmental), and 45001 (Occupational Health & Safety) certifications, Maiterio Group's processes are transparent, repeatable, and aligned with the expectations of global giants in energy, wind power, and heavy industry.

Choosing pelleting dies forging is an investment in durability, reliability, and operational efficiency. The process's ability to create a superior metallurgical structure is unmatched by alternatives. By focusing on critical aspects such as heat treatment for forged pelleting dies, selecting the correct alloy steel for pelleting die forging, and adhering to rigorous pelleting die forging quality control standards, manufacturers can achieve exceptional die performance. A thorough cost analysis of forged vs cast pelleting dies reveals the true long-term value, and a proper pelleting die forging machine setup and maintenance regimen ensures consistent production quality. For partners seeking a technically adept and vertically integrated supplier, Maiterio Group provides a complete solution from premium alloy steel to precision-forged and machined components, engineered for the world's most demanding applications.

FAQs: Pelleting Dies Forging

1. What is the main advantage of forged pelleting dies over cast ones?

The primary advantage is a vastly superior internal grain structure. Forging eliminates porosity, refines the grain, and aligns it to better withstand stress, resulting in significantly higher fatigue strength, impact resistance, and longer service life.

2. How does heat treatment affect the performance of a forged pelleting die?

Heat treatment (hardening and tempering) is critical. It determines the final hardness for wear resistance and the toughness to resist cracking. An improperly heat-treated die, even if perfectly forged, will fail prematurely.

3. Which steel alloy is best for pelleting dies?

There's no single "best" alloy; it depends on the application. Chromium-based alloy steels like DIN 1.2379 are a common, excellent choice for general high-wear applications. For extreme abrasion or heat, high-speed or nickel-chromium steels may be selected.

4. Are forged pelleting dies worth the higher initial cost?

Absolutely. When conducting a total cost analysis, forged dies almost always have a lower total cost of ownership due to their longer lifespan (reducing replacement frequency and downtime) and more consistent pellet output quality.

5. What quality checks should I expect from a forging supplier for pelleting dies?

You should expect material certification, in-process dimensional checks, final full dimensional inspection, hardness testing at multiple locations, and non-destructive testing (like ultrasonic testing) to ensure the die is free from internal flaws.

References

[1] Roberts, G., Krauss, G., & Kennedy, R. (1998). *Tool Steels* (5th ed.). ASM International. This source provides detailed metallurgy on various tool steel classes, including the behavior of high-chromium cold work steels during heat treatment.

English

English Español

Español русский

русский