-

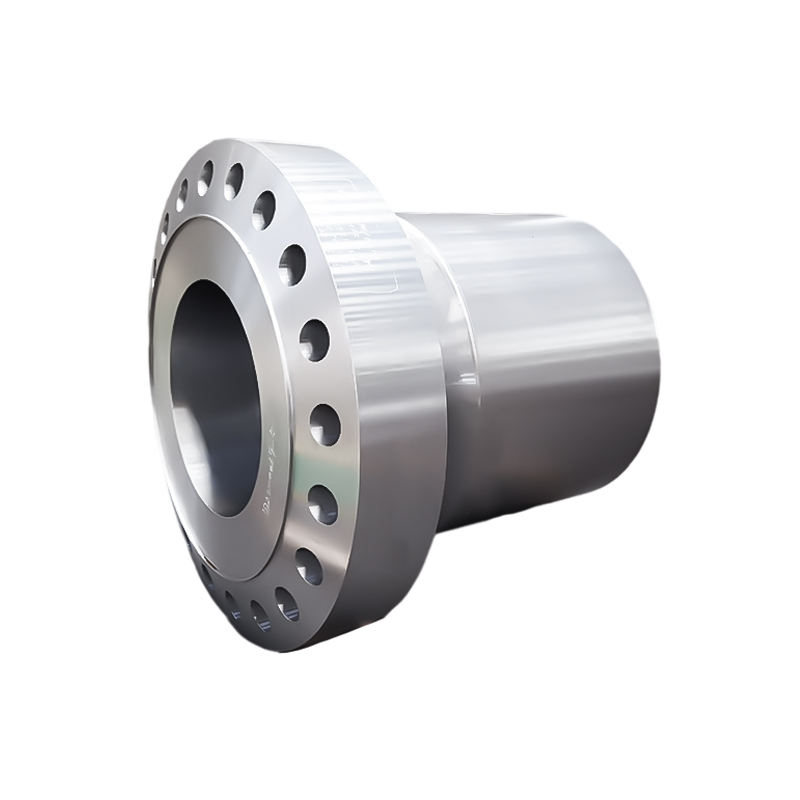

We offer forged shafts with different grades of materials, such as 18CrNiMo7-6, 4140/42CRMO4, 4340/EN24, 28CrMoNiV4-9 and etc.View Products

We offer forged shafts with different grades of materials, such as 18CrNiMo7-6, 4140/42CRMO4, 4340/EN24, 28CrMoNiV4-9 and etc.View Products -

We offer forged gears with all kinds of materials, with excellent mechanical performances and grain sizes.View Products

We offer forged gears with all kinds of materials, with excellent mechanical performances and grain sizes.View Products -

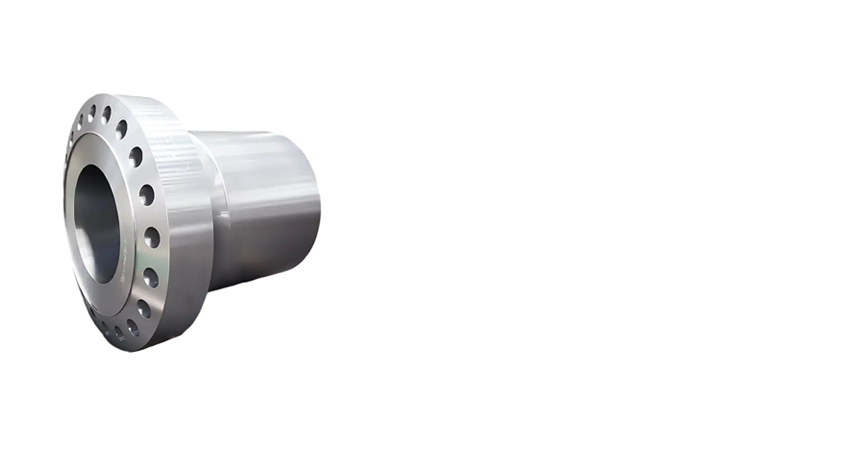

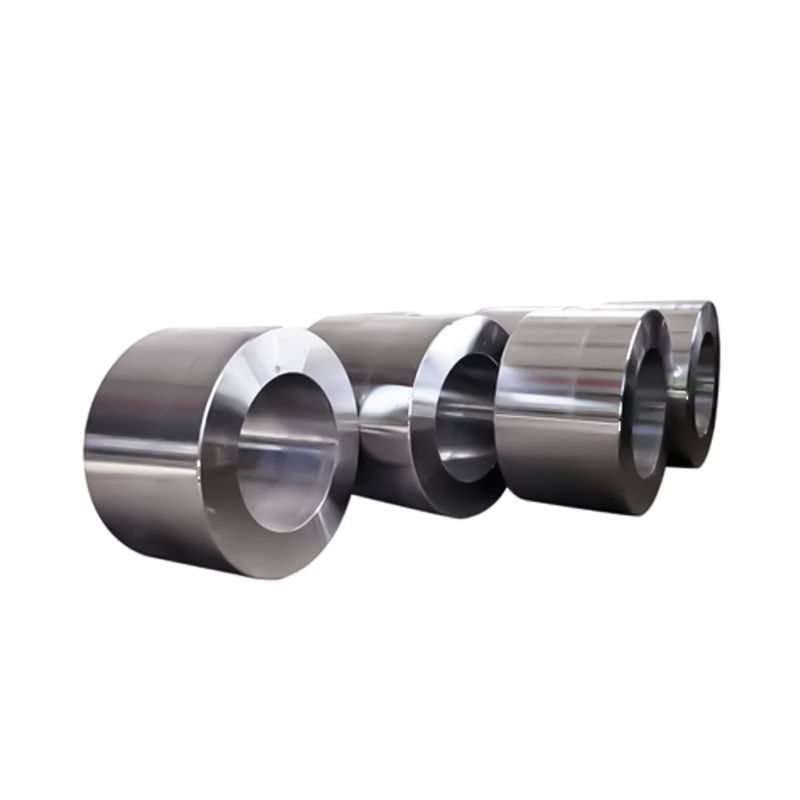

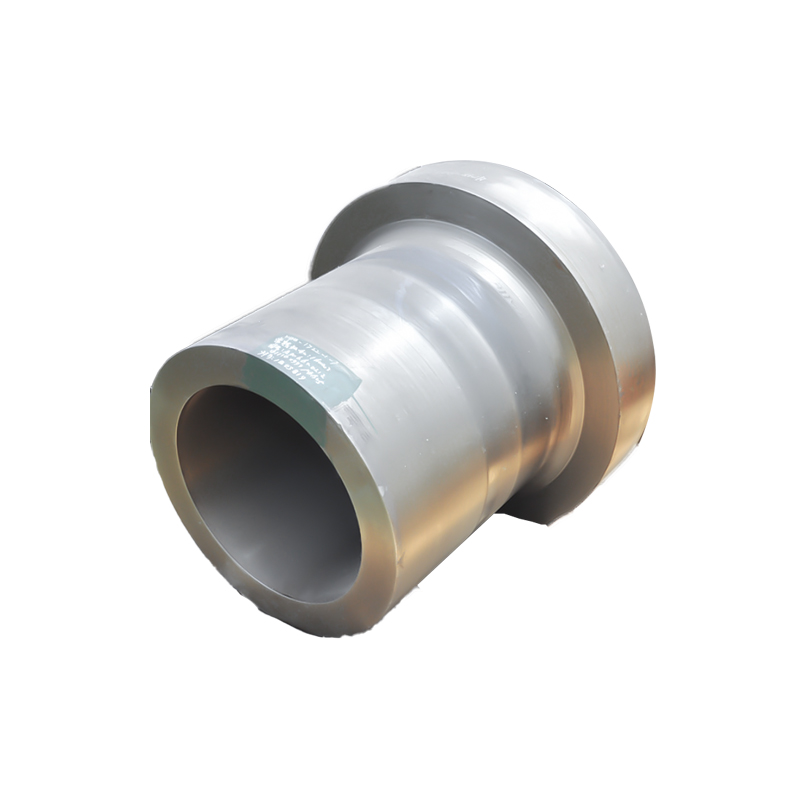

We have excellent expertise in forged cylinders, with a combination of ring forging and open die forging techniques to lower the forging allowances needed Special Material Forgings.View Products

We have excellent expertise in forged cylinders, with a combination of ring forging and open die forging techniques to lower the forging allowances needed Special Material Forgings.View Products

Open Die Forging Parts Factory

-

Metallurgical Equipment Field Forged Shaft

Metallurgical Equipment Field Forged Shaft

-

Energy and Power Field Forged Shaft

Energy and Power Field Forged Shaft

-

Construction Machinery Field Forged Shaft

Construction Machinery Field Forged Shaft

-

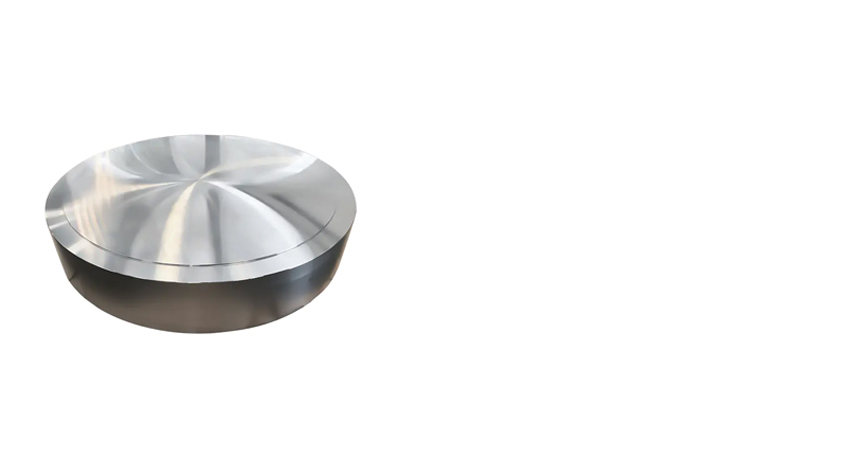

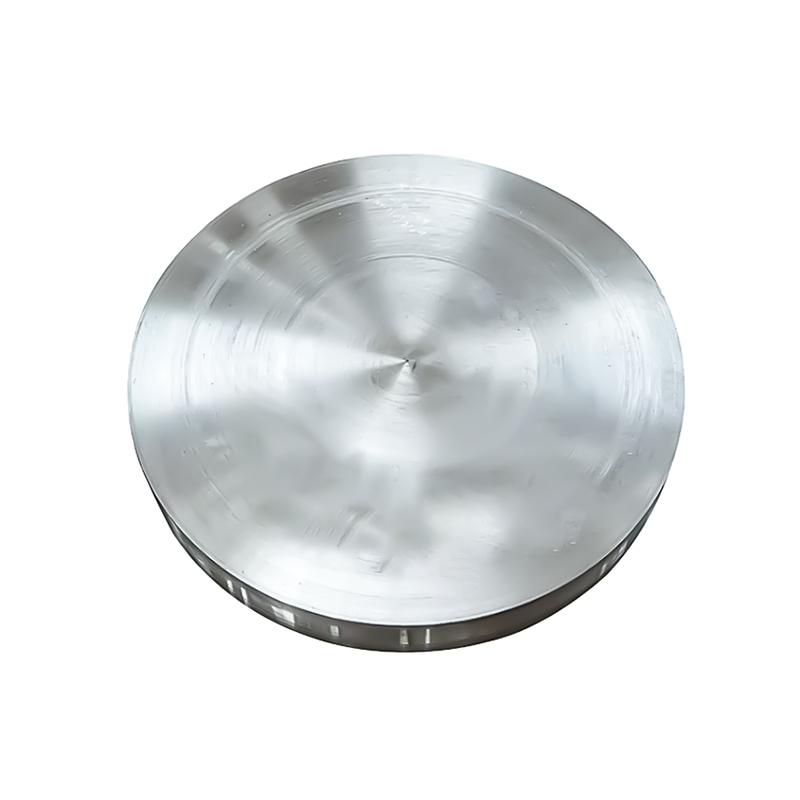

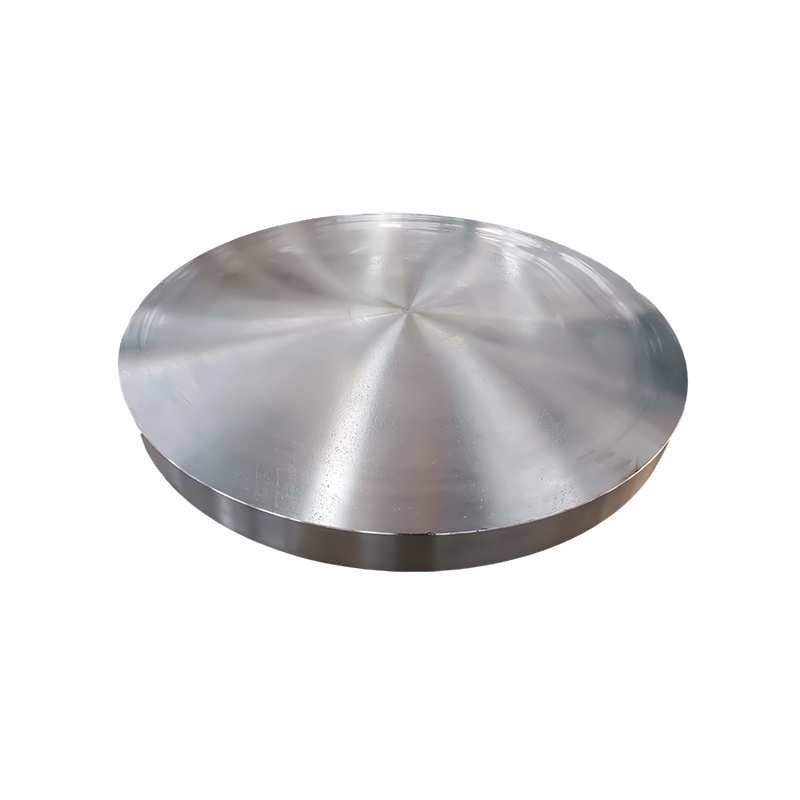

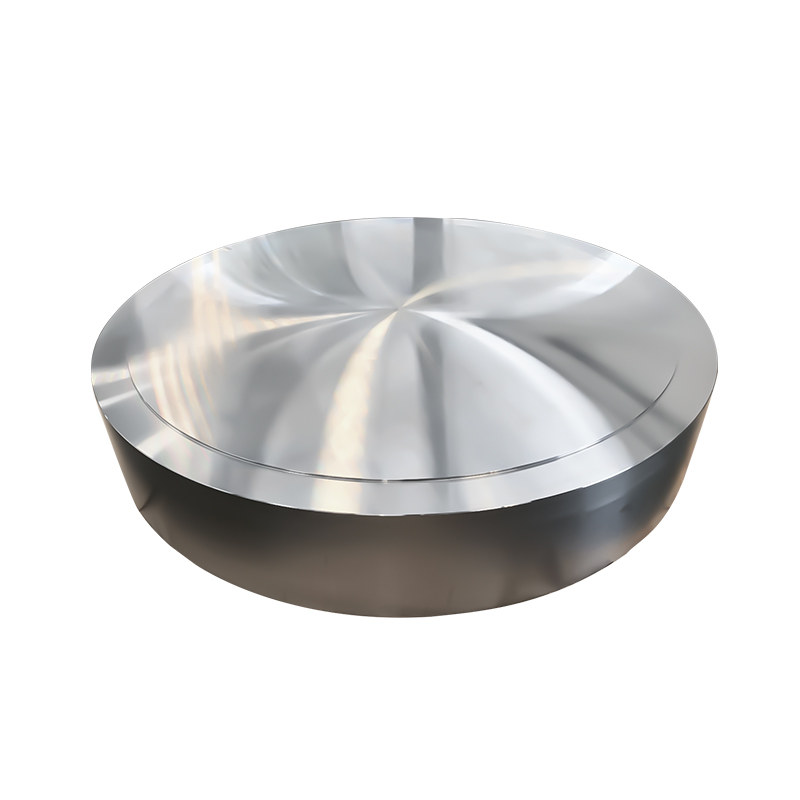

Metallurgical Equipment Field Forged Gears Discs

Metallurgical Equipment Field Forged Gears Discs

-

Mining Machinery Field Forged Gears Discs

Mining Machinery Field Forged Gears Discs

-

Energy and Power Equipment Field Forged Gears Discs

Energy and Power Equipment Field Forged Gears Discs

-

Heavy Construction Machinery Field Forged Gears Discs

Heavy Construction Machinery Field Forged Gears Discs

-

Metallurgical Equipment Field Forged Cylinder

Metallurgical Equipment Field Forged Cylinder

-

Mining and Heavy Machinery Field Forged Cylinder

Mining and Heavy Machinery Field Forged Cylinder

-

Energy and Power Equipment Field Forged Cylinder

Energy and Power Equipment Field Forged Cylinder

Why are Open Die Forgings so crucial in high-end manufacturing?

In modern industrial manufacturing, the performance and processing methods of materials directly determine the reliability and lifespan of products. Open die forgings, as a high-end manufacturing technology, are increasingly becoming an indispensable core material in industries such as aerospace, energy, and heavy machinery. So, what are open die forgings, and why do they stand out in these demanding applications?

What are Open Die Forgings?

Open die forging, also known as free forging, refers to the process of plastically deforming a metal billet in an open forging die through hammering or pressure to form parts of the desired size and shape. Compared to closed die forging, open die forging is characterized by its processing flexibility, suitability for large-sized parts, and high material utilization rate.

This process not only maintains the integrity of the metal's internal structure but also significantly improves the mechanical properties of the parts, including tensile strength, toughness, and fatigue strength. Therefore, many high-performance applications, such as large wind turbine shafts, ship main shafts, and heavy engineering machinery components, rely on open die forgings.

What are the advantages of Open Die Forgings?

Excellent Material Performance

Open die forging, through plastic deformation at high temperatures, eliminates internal pores and inclusions in the metal, resulting in a dense and uniform internal structure of the part. This means that under high loads or extreme working conditions, the parts are less prone to cracking or fatigue failure. This is why international giants like GE Vernova, Vestas, Caterpillar, Siemens Energy, and Komatsu all choose high-quality forgings as core components.

High Flexibility and Wide Applicability

Because it is not limited by fixed molds, open die forging can manufacture parts of extremely large sizes or complex shapes. For example, large ring forgings, thick-walled shaft parts, and various customized high-performance components can all be produced through free forging. This flexibility allows designers to optimize part structure and weight ratio without increasing material waste, thereby improving overall system performance.

Efficient Production and Cost Control

Modern open die forging processes, combined with precision control systems and automated forging lines, can significantly shorten production cycles, reduce material waste, and ensure product quality stability. Especially in mass production, a well-designed open die forging production line can achieve higher capacity and consistency, saving production costs for enterprises and enhancing market competitiveness.

How does Zhangjiagang Maiterio lead the Open Die Forgings industry?

As a high-end manufacturing enterprise, Zhangjiagang Maiterio Intelligent Equipment Company possesses unique advantages in the open die forging field:

Self-Designed Forging Production Lines

Maiterio is not only a user of open die forging but also a designer. We deeply understand the key technical details of forging production and can design more efficient and precise forging production lines. Through independent design, we can achieve smaller forging allowances and faster production cycles, while ensuring that the internal structure of each forging is dense and its mechanical properties are optimal.

Top-Tier Steel Procurement and Quality Control

Maiterio is the largest customer of Yonggang, one of China's top three alloy steel manufacturers. This means we have the most competitive prices in steel procurement, and our internal consumption guarantees the quality of the steel. Combined with a strict management system based on ISO 9001/14001/45001 standards, we ensure that the quality of our forgings reaches the highest international standards at every stage.

Extensive Industry Experience and Technical Expertise

Our team members all have over 30 years of industry experience, possessing rich technical expertise and practical experience in ring forgings, shaft forgings, and precision machined parts. This profound technical background enables Maiterio to provide the most professional solutions in complex part design, production process optimization, and customized customer needs.

Comprehensive Production and Processing Capabilities

Maiterio covers an area of over 50,000 square meters and has 3 ring forging production lines, 2 open die forging production lines, and 2 machining workshops equipped with more than 70 CNC machine tools. This scale and equipment ensure that we can handle both large-sized forgings and high-precision parts simultaneously, providing customers with one-stop forging and machining services.

Why choose Maiterio's Open Die Forgings?

By choosing Maiterio, customers not only receive high-quality forgings but also gain professional services and reliable guarantees throughout the entire process:

- High-Performance Forgings: Dense internal structure and excellent mechanical properties.

- Fast Response: Self-designed production lines and high-capacity machining workshops ensure delivery times.

- Global Recognition: Providing components to international giants such as GE Vernova and Siemens Energy, demonstrating globally trusted quality.

- One-Stop Solution: Covering the entire industrial chain from steel procurement and forging to precision machining.

FAQ

| Q1: What types of parts are suitable for open die forging? | A1: It is suitable for large-sized, thick-walled, complex-shaped parts or components requiring high mechanical properties, such as large shafts, rings, and customized high-performance components. |

| Q2: What are Maiterio's advantages in open die forging compared to other manufacturers? | A2: Maiterio has its own independently designed forging production line, superior steel procurement channels, a strict quality control system, and over 30 years of technical experience, enabling us to provide high-efficiency and high-performance forgings. |

| Q3: How long is the typical delivery time? | A3: Depending on the size and quantity of the parts, the lead time from material procurement to completion can be flexibly adjusted. Thanks to our independent production line, we can significantly shorten delivery times. |

| Q4: Can you provide customized solutions? | A4: Absolutely. The Maiterio team has extensive experience in customization and can perform material selection, process design, and precision machining according to customer needs. |

English

English Español

Español русский

русский