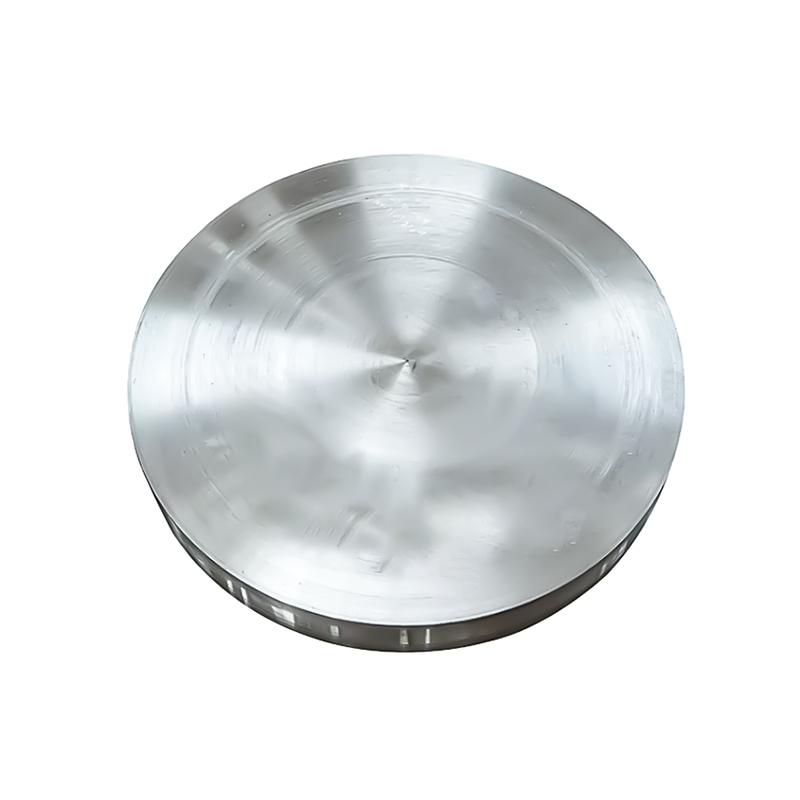

Customized Metallurgical Equipment Field Forged Gears Discs

Home / Products / Forging / Open Die Forging / Forged Gears/Discs / Metallurgical Equipment Field Forged Gears Discs

Application scenarios: Main drive gears of rolling mills (herringbone gears and cylindrical gears for hot rolling mills and cold rolling mills), gears in continuous caster transmission gearboxes, gears for metallurgical cranes, etc.

Working conditions: Withstand extremely high rolling torque (tens of thousands of N·m), high temperature (partially close to 1000°C), and alternating stress; large in size (1-5 meters in diameter).