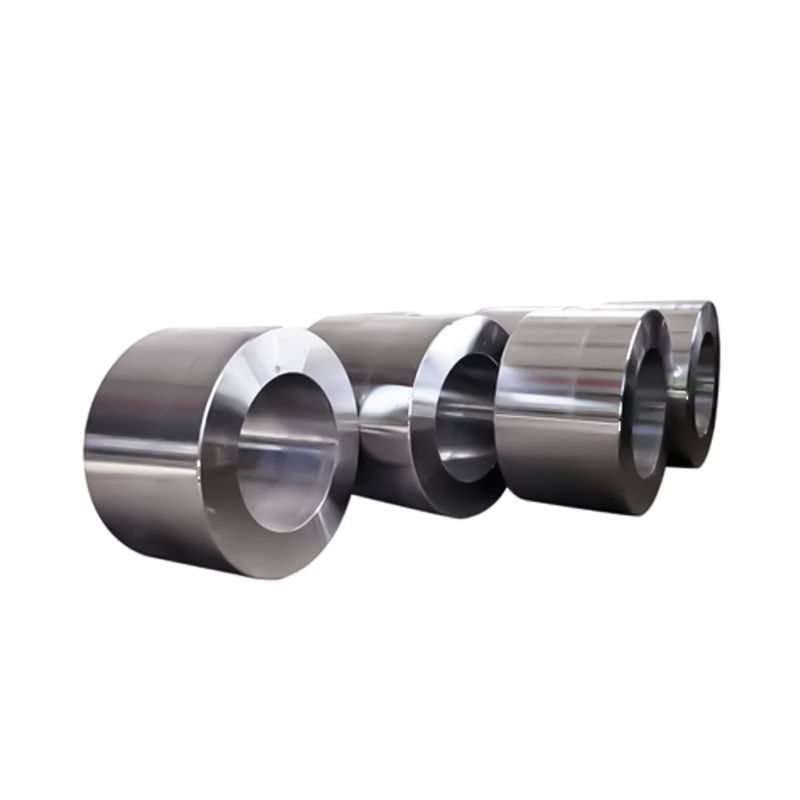

Customized Metallurgical Equipment Field Forged Cylinder

Home / Products / Forging / Open Die Forging / Forged Cylinder / Metallurgical Equipment Field Forged Cylinder

Application scenarios: Roll sleeves of rolling mills, furnace body cylinders of steelmaking converters (some key load-bearing sections), outer sleeves of continuous caster moulds, etc.

Working conditions: Withstand high temperatures (up to 800-1000°C in steel rolling scenarios), rolling forces or impact loads, requiring high-temperature strength and wear resistance.