The manufacturing world relies on robust, reliable, and high-performance components. Among the various metalworking techniques, forging stands out for creating parts with unparalleled strength and structural integrity. Stainless steel forgings are particularly critical in demanding sectors where corrosion resistance, high strength, and reliability are non-negotiable. This guide delves deep into the world of stainless steel forgings, exploring their processes, advantages, and how they form the backbone of modern industry.

What Are Stainless Steel Forgings?

Forging is a manufacturing process where metal is shaped using localized compressive forces, typically delivered by a hammer or die. When applied to stainless steel—an alloy known for its chromium content and corrosion resistance—this process refines the metal's grain structure, aligning it with the shape of the part. This results in components with superior mechanical properties compared to those made by casting or machining from bar stock.

The process is essential for creating parts that must withstand extreme stress, pressure, or environmental conditions. From the heart of a wind turbine to the landing gear of an aircraft, stainless steel forgings provide the necessary durability.

Key Advantages of Choosing Forged Stainless Steel

Why specify a forged component over alternatives? The benefits are rooted in material science and performance.

Superior Strength and Fatigue Resistance

- Grain Flow Enhancement: The forging process deforms the metal's internal grain structure, causing it to follow the contour of the part. This continuous grain flow eliminates weak points.

- Impact on Durability: Forged parts exhibit significantly higher fatigue strength and impact resistance, crucial for components in cyclic loading situations.

Enhanced Structural Integrity

- Elimination of Imperfections: The high pressure involved consolidates the metal, healing voids and porosity that can occur in castings.

- Predictable Performance: This leads to more reliable mechanical properties and a lower risk of catastrophic failure.

Economic Efficiency in High-Volume Production

- Material Savings: Forging, especially near-net-shape forging, uses material more efficiently than machining from a solid billet, reducing waste.

- Long-Term Value: While the initial cost may be higher, the extended service life and reduced maintenance of forged parts offer a better total cost of ownership.

Primary Forging Processes for Stainless Steel

Two main forging methods are employed for stainless steel, each suited for different part geometries and production scales.

Open-Die Forging

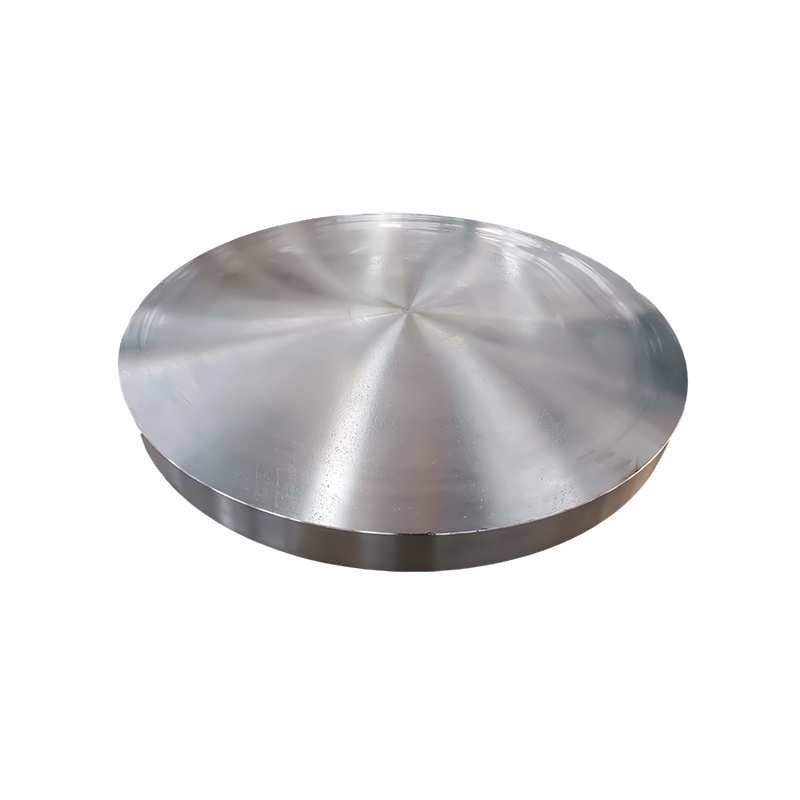

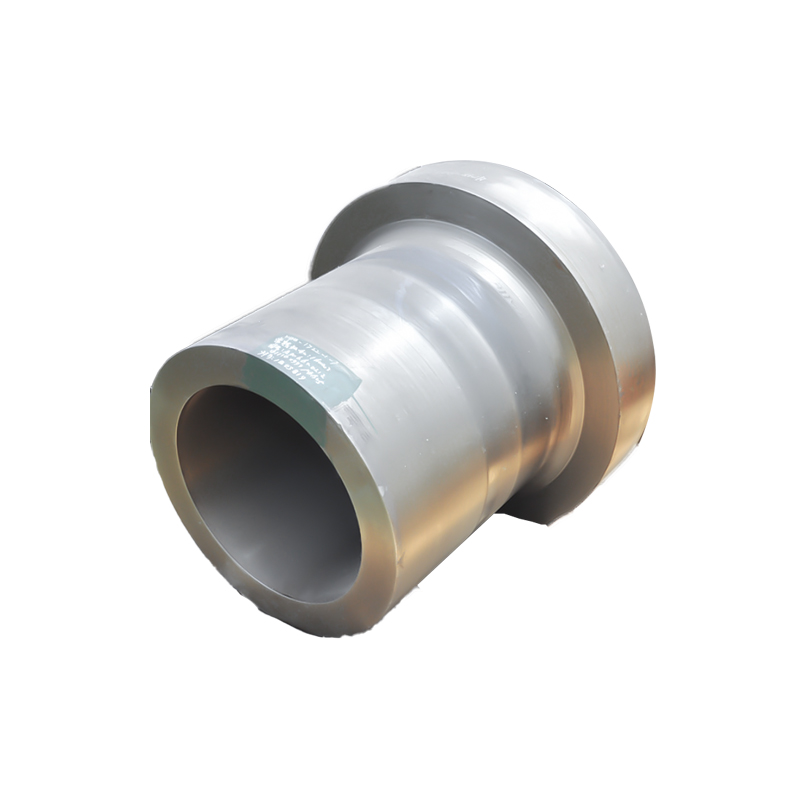

Also known as free forging, this process uses flat or simple-shaped dies. The workpiece is mechanically manipulated between dies, making it ideal for large, simple, or custom-shaped components like forged shafts and forged cylinders.

- Best For: Large parts, small-batch production, pre-forming for closed-die forging.

- Flexibility: Allows for the production of a wide variety of sizes and shapes.

Closed-Die Forging (Impression Die Forging)

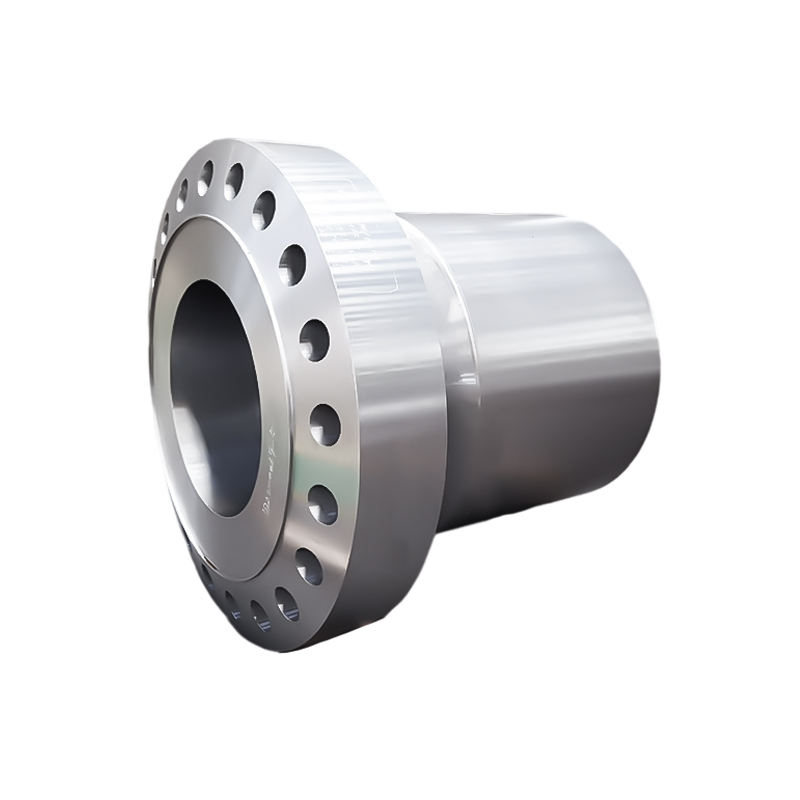

The metal is pressed between two dies that contain a precut impression of the desired part shape. This is used for high-volume production of complex, precise components.

- Best For: High-volume runs, complex geometries, near-net-shape parts.

- Precision: Offers excellent dimensional accuracy and repeatability.

Open-Die vs. Closed-Die Forging: A Comparison

The choice between open-die and closed-die forging depends on several factors. Below is a detailed comparison to guide the selection process.

| Parameter | Open-Die Forging | Closed-Die Forging |

|---|---|---|

| Tooling Cost | Relatively low (simple dies) | High (complex, custom dies) |

| Production Volume | Low to medium (prototypes, small batches) | High (mass production) |

| Part Complexity | Low to moderate (shafts, rings, blocks) | High (complex, intricate shapes) |

| Material Utilization | Lower (more machining often required) | Higher (near-net-shape production) |

| Dimensional Tolerance | Wider tolerances | Tighter tolerances |

| Lead Time for Tooling | Short | Long |

Specialized Forging: The Case of Seamless Rolled Rings

A critical subset of forging is the production of seamless rolled rings. This process involves piercing a forged stainless steel billet and then rolling it under pressure to enlarge its diameter, refine its grain structure, and achieve the required cross-section.

- Key Characteristics: Seamless, continuous grain structure, high strength-to-weight ratio.

- Primary Applications: Bearings, gear rings, flanges, and critical components in aerospace and energy (e.g., for wind turbines and gas turbines).

- Manufacturing Edge: Advanced manufacturers utilize dedicated ring rolling lines to control dimensions precisely and achieve smaller forging allowances, minimizing subsequent machining [1].

Ensuring Quality in Stainless Steel Forgings

Quality is not accidental. Reputable forgers adhere to stringent international standards and implement rigorous process controls.

Certification and Standards

- ISO 9001 (Quality), 14001 (Environmental), 45001 (Health & Safety): A comprehensive framework ensuring consistent quality, sustainable operations, and workplace safety.

- Industry-Specific Standards: Compliance with ASTM, ASME, EN, and customer-specific specifications for material chemistry and mechanical properties.

Advanced Process and Quality Control

- In-House Steel Sourcing Advantage: Some integrated manufacturers source directly from top-tier mills. This vertical integration, as seen with Maiterio's partnership with a leading alloy steel mill, guarantees traceability, competitive material costs, and control over the quality of the raw forging stock.

- From Forging to Finished Part: Modern facilities combine forging with extensive machining capabilities. A fleet of over 70 CNC machines allows for complete in-house finishing, ensuring tight coordination between the forging and machining stages for optimal results.

- Inspection Regime: This includes non-destructive testing (NDT) like ultrasonic testing for internal defects, liquid penetrant testing for surface cracks, and comprehensive dimensional checks using CMMs.

Industry Applications of Stainless Steel Forgings

The unique properties of forged stainless steel make it indispensable across heavy industry.

- Power Generation (Traditional & Renewable): Turbine shafts, rotor parts, and large diameter seamless rolled rings for wind energy nacelles and bearings.

- Heavy Machinery & Construction: Undercarriage components, pins, and corrosion resistant forged shafts for excavators and mining equipment that face abrasive and corrosive environments.

- Oil & Gas: Valves, wellhead components, and high-pressure fittings that require high temperature stainless steel forgings for turbines in compressor stations.

- Aerospace & Defense: Landing gear components, engine mounts, and structural airframe parts where strength, weight, and reliability are critical.

The Future of Forging: Technology and Integration

The forging industry continues to evolve, driven by digitalization and a demand for total solutions.

- Smart Forging Lines: The design of modern forging lines focuses on automation, precision, and data collection. Self-designed lines, informed by decades of operational experience, can achieve smaller forging allowances and higher production pace, optimizing both material use and throughput.

- Whole-Line Solution Offering: Progressive manufacturers now offer more than just forgings. This encompasses everything from steel trading and forging wholeline solution offering—providing the right material and forging expertise—to precision machining, delivering a ready-to-install component. This integrated approach reduces supply chain complexity and ensures quality at every step.

Stainless steel forgings represent the pinnacle of strength, durability, and performance for critical metal components. Understanding the processes—from creating open die forged blocks for machining blanks to manufacturing complex precision machined forgings for hydraulic cylinders—is essential for engineers and specifiers. By partnering with a certified, vertically integrated manufacturer that controls the process from raw material to finished part, industries can ensure they receive components that meet the highest global standards and stand up to the most demanding applications.

Frequently Asked Questions (FAQs)

1. What are the main grades of stainless steel used in forgings?

The most common grades include austenitic types like 304/304L and 316/316L for general corrosion resistance, martensitic types like 410 for high strength, and duplex grades like 2205 for superior strength and chloride resistance. The choice depends on the application's mechanical and environmental requirements.

2. How does forging improve the properties of stainless steel compared to casting?

Forging refines the metal's grain structure and aligns it with the part's shape, enhancing strength, ductility, and fatigue resistance. It also eliminates the porosity and internal voids common in castings, resulting in greater structural integrity and reliability [2].

3. What is the typical lead time for a custom stainless steel forging project?

Lead times vary significantly based on part complexity, tooling requirements, and quantity. Simple open-die forgings may take 4-8 weeks, while complex closed-die forgings requiring custom die design and fabrication can take 12-20 weeks or more. An integrated provider can often streamline this timeline.

4. Why is near-net-shape forging desirable?

Near-net-shape forging produces a part very close to its final dimensions. This dramatically reduces material waste (scrap) and minimizes the machining time and cost required to finish the component, offering both economic and environmental benefits.

5. Can forged stainless steel components be machined and welded after forging?

Yes, they can. However, it is crucial to consider the specific stainless grade and its post-forging condition. Machining parameters may need adjustment for work-hardened surfaces. Welding requires procedures that maintain corrosion resistance, often involving post-weld heat treatment for certain grades.

References

[1] Altan, T., & Tekkaya, A. E. (2012). *Forging Processes: Recent Developments*. In CIRP Encyclopedia of Production Engineering. Springer. (Reference related to advancements in ring rolling and forging line efficiency).

[2] Davis, J. R. (Ed.). (1994). *ASM Specialty Handbook: Stainless Steels*. ASM International. (Reference comparing the microstructures and properties of forged vs. cast stainless steel).

English

English Español

Español русский

русский