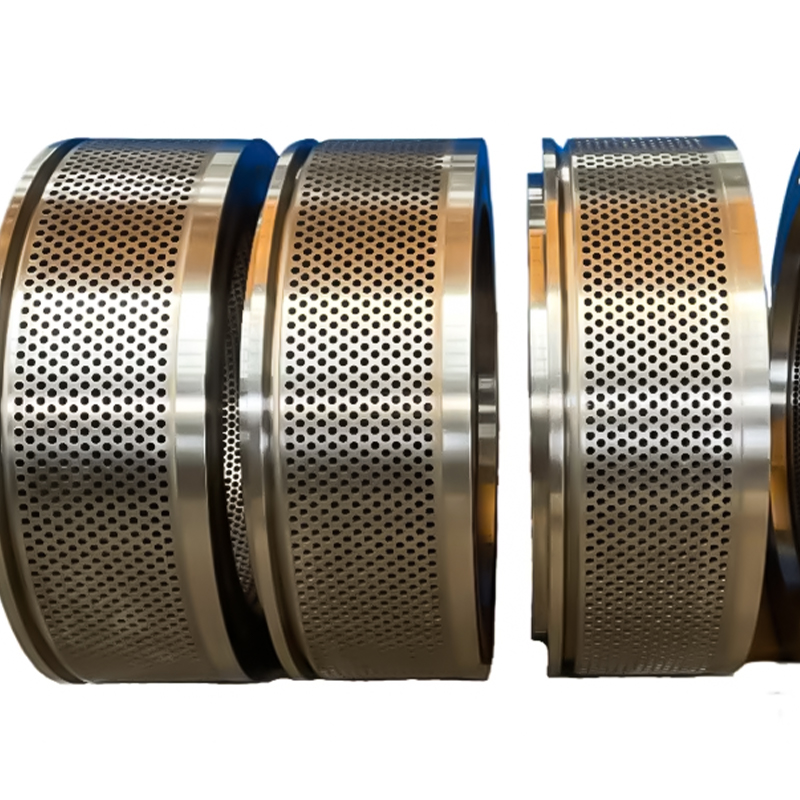

Pelleting Dies Forging

The ring die operates by using pressure rollers to force materials (such as wood chips, animal feed, or mineral slag) through densely arranged die holes (with diameters ranging 2-30mm) on the ring die surface, thereby forming cylindrical pellets.

- Performance Requirements

- Advantages

English

English Español

Español русский

русский