Wind Power Forgings Suppliers

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Wind Power Industry knowledge

What Are Wind Power Forgings and How Do They Contribute to the Renewable Energy Sector?

Wind power forgings are a vital component in the construction and operation of wind turbines. These forged parts, which include seamless rolled rings, shafts, and flanges, are specifically designed to withstand the immense stresses encountered in wind energy applications.

What Are Wind Power Forgings?

Wind power forgings are metal parts that are produced through a forging process, which involves shaping metal using localized compressive forces. The process typically produces high-strength components with improved mechanical properties compared to those made from casting. In the wind energy industry, forgings are essential for critical parts such as bearing races, gear rings, turbine support structures, and flanges used in wind towers.

A key characteristic of wind power forgings is that they often come in the form of seamless rolled rings. These rings are made from a hollow circular preform and undergo processes such as radial forging to achieve a highly efficient grain flow, which results in exceptional strength along the part’s circumference. This gives the forged components their ability to handle the intense loads experienced in wind turbines.

Key Characteristics of Wind Power Forgings

Wind power forgings are known for several characteristics that make them ideal for use in demanding applications like wind turbines:

-

Radial Grain Flow: One of the primary advantages of forgings is their ability to maintain a radial grain flow, which enhances the strength of the component in the circumferential direction. This is especially important in applications like bearing races and turbine gear rings, where strength and durability are critical.

-

High Dimensional Accuracy: Forged components can achieve excellent dimensional accuracy, which ensures a perfect fit in assembly applications. This precision is crucial in maintaining the overall efficiency and safety of wind turbines.

-

Material Yield: The forging process allows for optimal use of material, resulting in higher material yield compared to other manufacturing methods. This reduces waste and improves the cost-effectiveness of producing high-quality components.

Forging Process for Wind Power Components

The manufacturing process for wind power forgings typically involves several stages, including:

-

Preform Preparation: A hollow circular preform, typically made from high-strength steel, is prepared for the forging process. The size and shape of the preform depend on the final component’s specifications.

-

Radial Forging: The preform undergoes radial forging, a specialized process that applies compressive forces from all directions to shape the metal. This process ensures that the material’s grain flow follows the desired direction, enhancing strength and performance.

-

Heat Treatment: After forging, the components undergo heat treatment to improve their mechanical properties, including hardness, strength, and ductility. This process ensures that the forgings can withstand the extreme conditions they will encounter in the field.

-

Machining: Once the forging process is complete, the components are precision-machined to achieve the final dimensions and surface finish required for their intended application.

-

Quality Control: Rigorous quality control measures are taken throughout the manufacturing process to ensure that the forgings meet the required standards for safety, performance, and durability.

Applications of Wind Power Forgings

Wind power forgings are used in various critical components within wind turbines and wind power systems. Some of the primary applications include:

-

Bearing Races: Bearing races are essential for supporting the rotating shafts within wind turbines. The high strength and dimensional accuracy of forged bearing races ensure the reliable performance of the turbine’s rotating system, even under heavy loads.

-

Gear Rings: Forged gear rings are used in the gearboxes of wind turbines. These components are subjected to high mechanical stresses as they transmit the rotational force from the blades to the generator. Forged gear rings are ideal for this application due to their strength and resistance to wear.

-

Turbine Support Structures: Wind turbine towers require robust structural components to support the weight of the nacelle and blades. Forged parts, such as flanges and support structures, are used to ensure the stability and safety of the entire system.

-

Flanges for Wind Towers: Flanges are critical in connecting various sections of the wind turbine tower. Forged flanges provide superior strength and reliability, ensuring the structural integrity of the tower even in challenging weather conditions.

-

Rotary System Components: Components used in the rotary systems of wind turbines, including shaft couplings and other high-performance parts, benefit from the strength and precision of wind power forgings. These parts are essential for the smooth operation of turbines, contributing to their efficiency and longevity.

Why Choose Forgings for Wind Power Applications?

Forged components are preferred over cast or machined alternatives in wind power applications for several reasons:

-

Superior Strength and Durability: The radial grain flow in forgings provides enhanced strength, which is essential for components that must endure the constant stress and strain encountered in wind turbines. Forged parts can withstand higher loads and have a longer service life than other materials.

-

Resistance to Fatigue and Wear: Forged components are highly resistant to fatigue and wear, which is crucial in high-stress applications like wind power. This resistance ensures that parts like gear rings and bearing races maintain their integrity over time, reducing maintenance costs and downtime.

-

Cost Efficiency: While the initial manufacturing process for forgings can be more expensive than casting, the long-term benefits of increased reliability and reduced maintenance make forgings a cost-effective choice for wind power applications.

Industry Insights

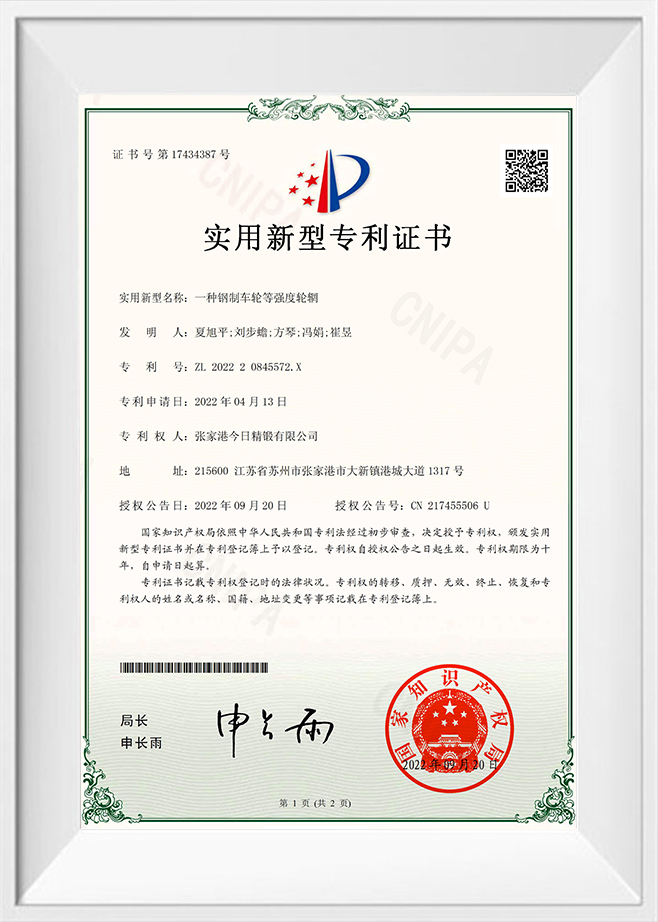

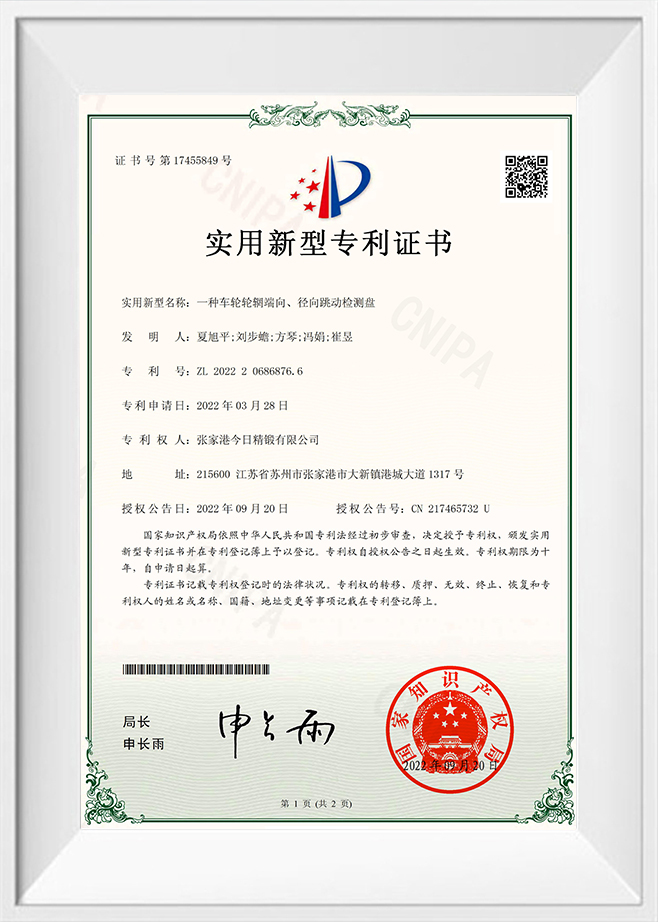

Maiterio Group is a leading manufacturer specializing in high-performance forgings, including seamless rolled rings and forged shafts. With over 30 years of experience in forging production lines, Maiterio Group has developed a streamlined and efficient manufacturing process that ensures high-quality, cost-effective components for industries like wind power.

As the largest customer of Yong Gang, one of China’s top alloy steel mills, Maiterio Group enjoys competitive steel purchase prices, ensuring cost efficiency and quality control throughout the production process. The company’s focus on integrating design, manufacturing, and service enables them to deliver not only products but also long-term value and competitive advantage to their clients in the wind power sector.

Conclusion

Wind power forgings play a crucial role in the performance, reliability, and efficiency of wind turbines and related systems. The unique characteristics of forged components, such as radial grain flow and high material yield, make them ideal for the demanding applications in the wind power industry. Maiterio Group specializes in manufacturing these components, enabling the renewable energy industry to continuously benefit from high-quality, durable parts, thereby contributing to the clean energy transition.

English

English Español

Español русский

русский