-

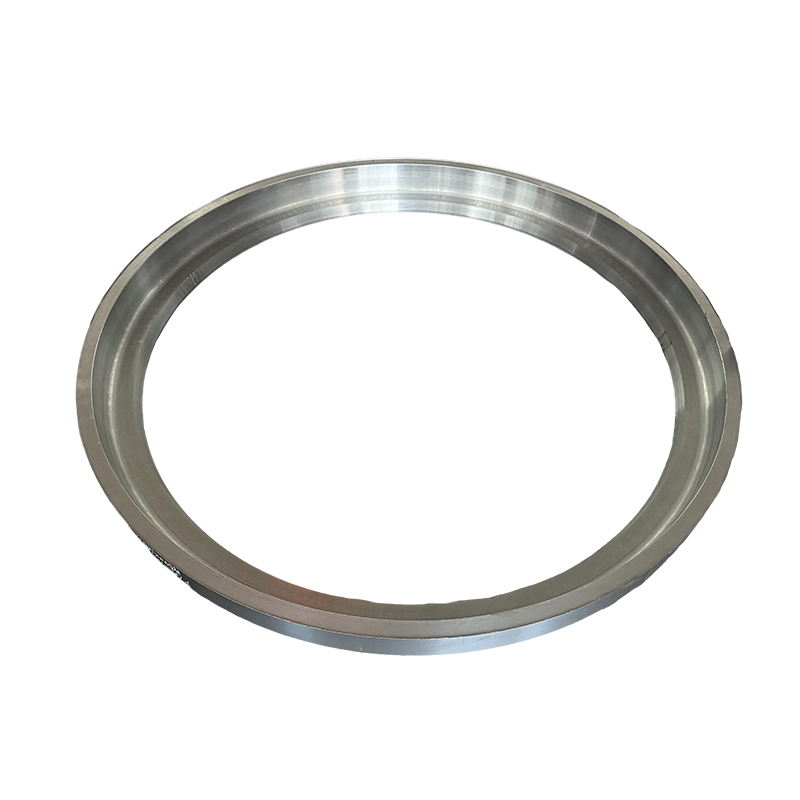

We offer 42CRMO4 and S355 materials for pitch ring, yaw ring and flange applications in wind power area.View Products

We offer 42CRMO4 and S355 materials for pitch ring, yaw ring and flange applications in wind power area.View Products -

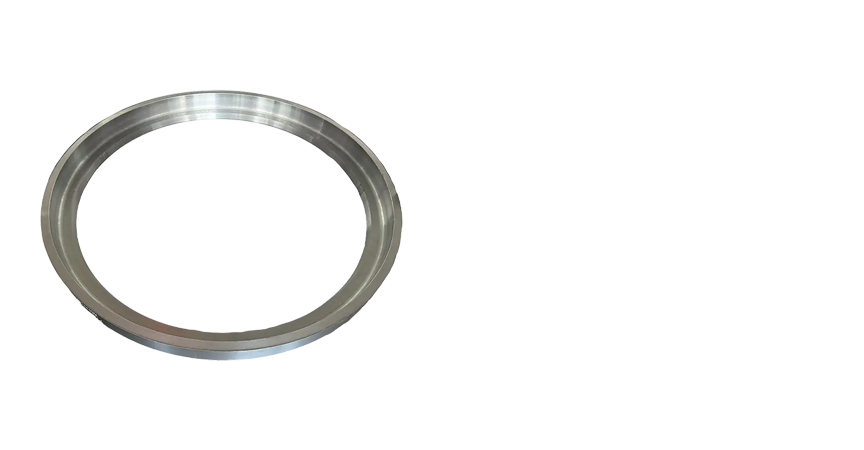

We offer 42CRMO4, 20CRMO, 4340, C45 and C28 rings for engineering machinery field.View Products

We offer 42CRMO4, 20CRMO, 4340, C45 and C28 rings for engineering machinery field.View Products -

We offer 20MNV6 and 42CRMO4 rings for mining machinery field.View Products

We offer 20MNV6 and 42CRMO4 rings for mining machinery field.View Products -

We primarily offer X46CR13/4CR13 rings for pelleting dies for global customers.View Products

We primarily offer X46CR13/4CR13 rings for pelleting dies for global customers.View Products

Rolled Ring Forging Factory

What Are the Most Easily Overlooked Key Factors When Choosing a Rolled Ring Forging Supplier?

In high-end equipment fields such as wind power, energy, and construction machinery, there is a type of critical component that is often not directly seen by end-users, yet it determines the safety, lifespan, and reliability of the entire machine – this is Rolled Ring Forging. What makes it occupy such an important position in global high-end manufacturing?

What Is Rolled Ring Forging and Why Is It Irreplaceable?

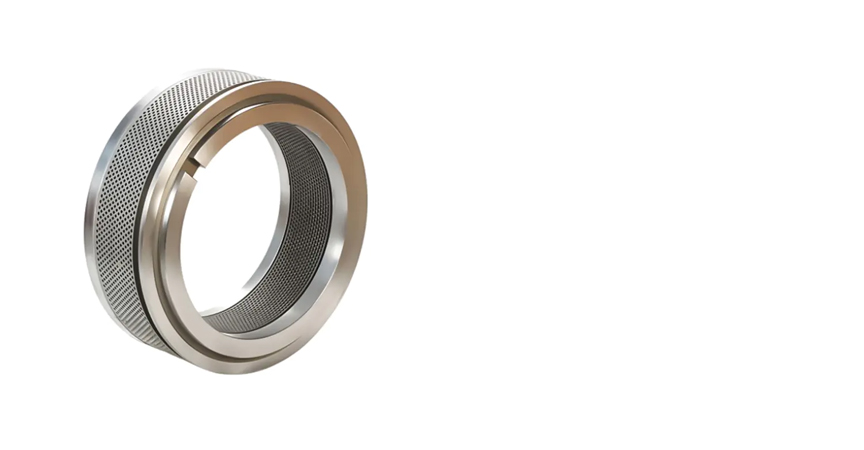

Rolled Ring Forging is an advanced forging process that gradually expands the diameter, reduces the wall thickness, and improves the metal structure of a ring-shaped blank through radial and axial rolling. Compared with cast or welded rings, rolled ring forgings have several significant advantages:

- Continuous fiber flow lines: Significantly improved fatigue strength and impact resistance

- Dense internal structure: Very few internal defects, resulting in a higher safety factor

- Excellent dimensional consistency: Provides a stable foundation for subsequent precision machining

Because of these characteristics, rolled ring forgings are widely used in applications with extremely high reliability requirements, such as wind turbine main shaft bearing rings, gas turbine components, construction machinery slewing bearings, and critical ring components for energy equipment.

What New Challenges Do High-End Applications Pose for Rolled Ring Forging?

With the continuous increase in wind turbine capacity and the rapid development of energy equipment toward higher temperature and pressure operating conditions, rolled ring forging is facing several new challenges.

Larger Sizes and More Complex Materials

Large alloy steels, stainless steels, and special steel grades place much higher demands on heating uniformity, deformation control, and cooling strategies.

More Stringent Quality Standards

International customers commonly require compliance with multiple standards such as ISO, EN, and ASTM, as well as full material and process traceability.

Dual Pressure of Cost and Delivery Time

Reducing forging allowance while increasing production efficiency—without compromising performance—has become a key competitive differentiator.

From Equipment to Process: Where Does Real Competitiveness Lie?

In this regard, the practice of Zhangjiagang Maiterio Intelligent Equipment Company is highly representative.

Founded in 2019, Maiterio Group specializes in seamless rolled ring forgings, forged shafts, forged cylinders, and precision-machined components. However, its true strength lies not only in what it produces, but in how it produces them.

- 3 rolled ring forging lines and 2 open-die forging lines, covering multiple specifications and steel grades

- 50,000 square meters of production space with over 70 CNC machines, enabling integrated forging and machining

- Founding and core teams with over 30 years of industry experience, deeply familiar with process windows and failure mechanisms

Maiterio is not merely an equipment owner, but a long-term process user and optimizer. Decades of hands-on production experience allow the company to design forging lines with smaller allowances, higher production cadence, and more stable metallurgical control.

Why Materials Often Determine the Upper Limit of Forging Performance

The importance of raw materials in rolled ring forging is often underestimated. In reality, steel cleanliness and batch consistency frequently determine the ultimate performance ceiling of a forged component.

In 2024, Maiterio expanded its business into steel trading and complete forging line solutions. As one of the largest customers of Yong Gang—one of China’s top three alloy steel manufacturers—Maiterio benefits from:

- Highly competitive steel procurement costs

- Quality control standards equivalent to internal mill consumption

- Full-process consistency management from steelmaking to finished forgings

This integrated capability—combining materials, process expertise, and equipment design—enables Maiterio to deliver stable, reliable solutions to global customers such as GE Vernova, Vestas, Caterpillar, Siemens Energy, and Komatsu.

FAQ

Q1: Is Rolled Ring Forging more expensive than cast rings?

A: The manufacturing cost per piece may be slightly higher, but rolled ring forgings offer clear advantages in fatigue life, safety margin, and total life-cycle cost.

Q2: Is rolled ring forging suitable for small batches and multiple varieties?

A: Yes. With optimized production line design and process parameters, flexibility and efficiency can be effectively balanced.

Q3: How can quality consistency be ensured for large rolled ring forgings?

A: The key lies in raw material stability, robust process control, and accumulated operational experience—this is where mature forging suppliers differentiate themselves.

Q4: What is Maiterio’s core competitiveness?

A: Beyond equipment scale, Maiterio’s strength lies in 30 years of forging know-how, a globally aligned quality management system, and a fully integrated understanding from steel selection to finished components.

English

English Español

Español русский

русский