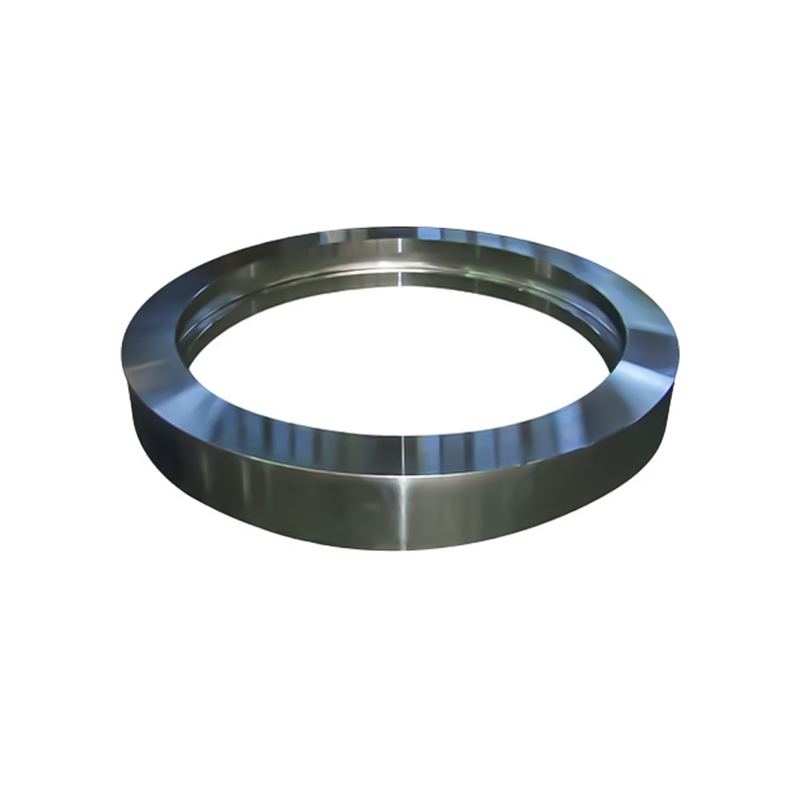

Connecting ring

For mining excavators (such as 400-ton-class electric shovels), the dipper must drive the bucket to excavate hard rock or slag. The connection between the dipper, boom, and bucket relies on large forged rings (with diameters reaching 1-2 meters), which must withstand bending moments and tensile forces during excavation (for electric shovels with 50m³ bucket capacity, single digging forces can reach hundreds of tons).

- Performance Requirements

- Advantages

English

English Español

Español русский

русский