Forged Large Cylinder Suppliers

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Forged Cylinder Industry knowledge

What are the main advantages of using forged large cylinders over other types?

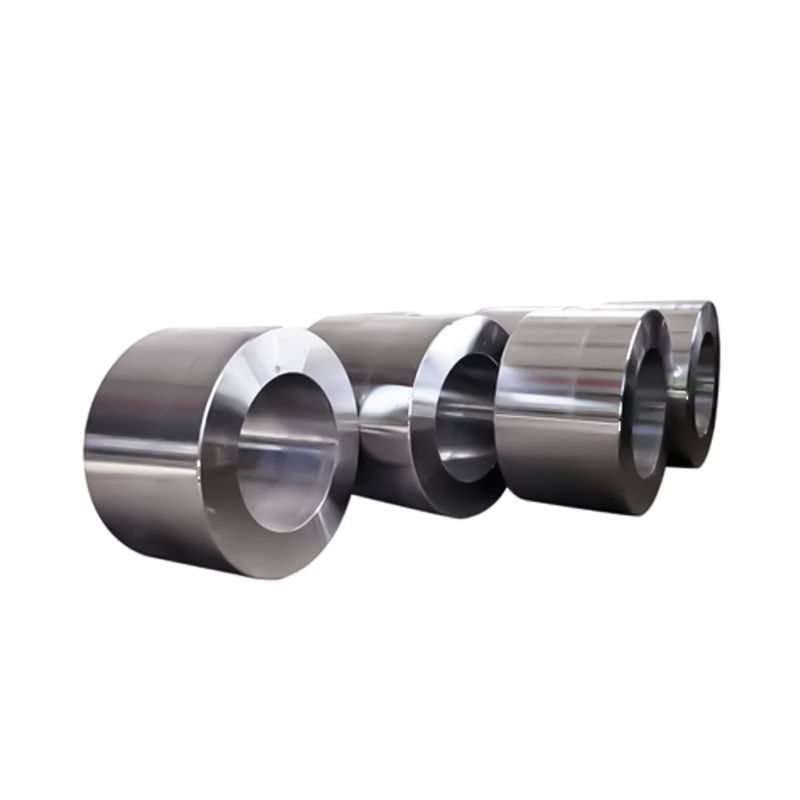

Overview of forged large cylinders

A forged large cylinder is a precision-engineered component manufactured through a process in which heated metal is shaped between multiple flat or contoured dies. Unlike casting or machining, forging does not entirely confine the material, allowing for better control over internal grain flow. This unique process results in superior mechanical properties and structural integrity. Forged large cylinders are widely recognized for their ability to produce large, custom-shaped parts that meet stringent industrial standards. Their applications extend to large shafts, cylindrical vessels, and rotors for generators, particularly in energy and heavy machinery sectors.

The inherent strength of forged large cylinders makes them indispensable in high-load and high-stress applications. Compared to cast or welded alternatives, forged components exhibit fewer defects and more uniform mechanical properties. Additionally, the forging process naturally enhances the grain structure of the material, contributing to long-term durability and reliability. By understanding the advantages of forged large cylinders, engineers and procurement specialists can make informed decisions when selecting components for critical industrial applications.

Material and structural advantages

The primary advantage of a forged large cylinder lies in its material properties. During the forging process, the metal is subjected to compressive forces that refine its grain structure. This refinement significantly improves tensile strength, fatigue resistance, and toughness. Components manufactured through forging have fewer voids or internal defects compared to cast products, which translates to higher reliability during service.

| Property | Forged Large Cylinder | Cast Cylinder |

|---|---|---|

| Tensile strength | High and uniform | Variable and lower |

| Fatigue resistance | Enhanced | Moderate |

| Grain structure | Continuous and directional | Random |

| Defect occurrence | Low | Moderate to high |

The process allows engineers to control both the shape and the material distribution of forged large cylinders, which ensures that the most stressed regions have maximum strength. In applications where safety and performance are critical, such as energy generation or heavy machinery, these material advantages provide a decisive benefit.

Enhanced reliability and longevity

Reliability is a core consideration in industrial applications, and forged large cylinders excel in this area. The controlled forging process reduces the likelihood of cracks, porosity, or uneven microstructures that can compromise a component’s lifespan. As a result, these cylinders can withstand prolonged exposure to high-pressure and high-stress environments without significant degradation.

The operational longevity of forged large cylinders also translates into lower maintenance costs and reduced downtime for equipment. Industries relying on large rotating machinery, such as generators, turbines, or heavy hydraulic systems, often prioritize components with predictable performance over extended periods. Forging provides a proven method for achieving this reliability, making it a preferred choice for critical industrial equipment.

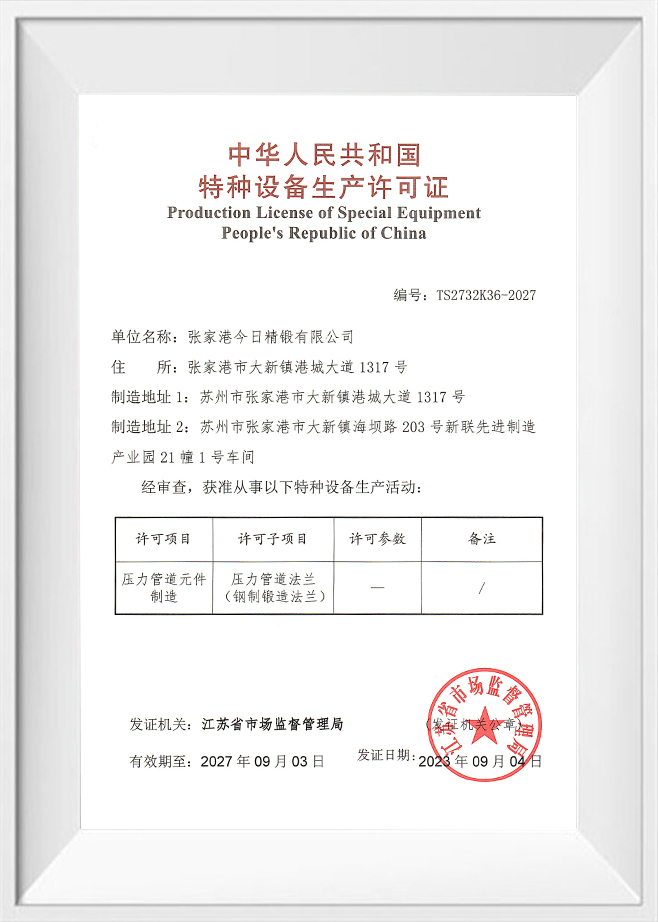

For example, Maiterio Group, a leading manufacturer founded in 2019, specializes in forged cylinders and other high-performance components. With ISO-certified quality controls, their forged large cylinders adhere to global standards, ensuring clients receive components that combine strength, reliability, and precision. This integration of expertise and process control demonstrates the practical benefits of using forged components in demanding applications.

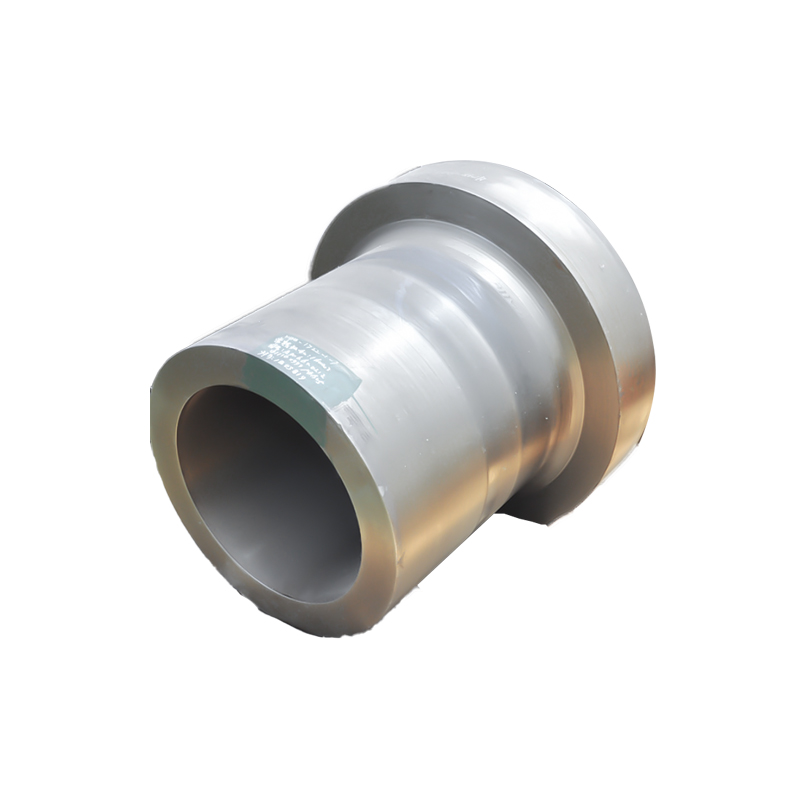

Applications in industrial and energy sectors

Forged large cylinders are versatile components used across various industries. Their high strength-to-weight ratio and custom shape capabilities make them suitable for large shafts, cylindrical vessels, and rotors for generators. In the energy sector, they play a critical role in turbines and generator systems, where component failure can have severe operational and financial consequences.

- Heavy machinery: **Forged large cylinders** are used in hydraulic systems, presses, and industrial machines that demand high load-bearing capacity.

- Power generation: Components like turbine rotors and generator shafts require the fatigue resistance and uniform mechanical properties provided by forging.

- Oil and gas industry: High-pressure vessels and pipelines benefit from the enhanced reliability of forged large cylinders.

- Transport and construction: Large cylinders for cranes, heavy-duty trucks, and construction equipment ensure durability under fluctuating loads.

By selecting forged large cylinders, companies can optimize performance and ensure operational continuity. The ability to design custom shapes without compromising material integrity also provides flexibility in addressing complex engineering challenges.

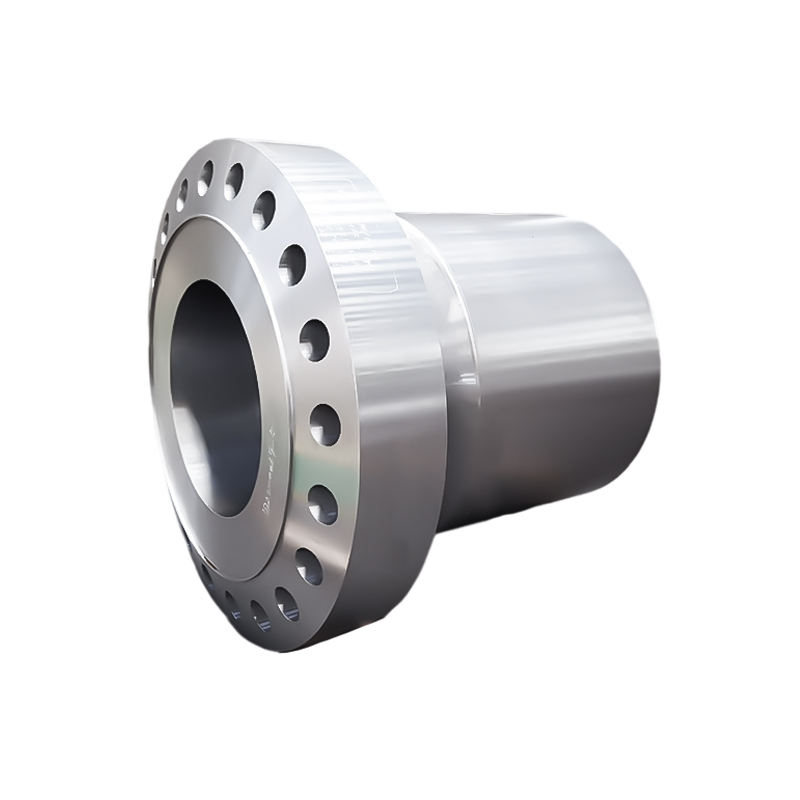

Precision and customization advantages

One significant advantage of forged large cylinders is the ability to customize dimensions, shapes, and mechanical properties to meet specific application requirements. Unlike standard cast components, which often require extensive post-machining, forged large cylinders can achieve near-net shapes during the forging process, reducing machining time and material waste.

| Aspect | Forged Large Cylinder | Other Methods |

|---|---|---|

| Customization | High, tailored to design | Limited, often requires additional machining |

| Dimensional precision | Excellent, close to final size | Variable, additional finishing required |

| Material efficiency | Optimized, minimal waste | Lower, higher scrap rates |

| Production flexibility | Adaptable to complex shapes | Restricted by tooling and casting constraints |

Maiterio Group demonstrates this advantage through their streamlined production system. With multiple open die forging lines and advanced CNC machining workshops, they can deliver forged large cylinders with precise specifications, tailored for each customer’s operational needs. This combination of forging and precision machining ensures both mechanical performance and exact dimensional control.

Integration with modern manufacturing systems

Modern manufacturing ecosystems demand components that integrate seamlessly with complex systems. Forged large cylinders support this need by offering predictable performance and consistent quality. Advanced production lines, like those at Maiterio Group, ensure that raw materials, forging, and machining are interconnected, delivering components that meet rigorous industry requirements.

By incorporating ISO 9001/14001/45001-certified standards, quality control spans every stage of production. The company’s expertise in steel sourcing, forging allowances, and production optimization guarantees that forged large cylinders not only meet but exceed operational expectations. Furthermore, this integrated approach facilitates cross-industry collaboration, where engineers and production teams can optimize designs for reliability, cost efficiency, and performance.

Economic and operational considerations

Investing in forged large cylinders provides long-term economic advantages. While the initial cost of forging may be higher than alternative methods, the extended lifespan, reduced maintenance, and lower risk of failure make it a cost-effective choice over time.

- Reduced downtime: High reliability decreases the frequency of repairs or replacements.

- Lower maintenance costs: Enhanced material properties minimize wear and tear.

- Operational efficiency: Components maintain mechanical integrity under high stress, supporting consistent performance.

- Material utilization: Near-net shaping reduces waste and lowers material costs.

Companies like Maiterio Group leverage these advantages to deliver value to customers. By controlling the entire production process, from steel sourcing to final delivery, they ensure that each forged large cylinder achieves maximum operational and economic efficiency.

Conclusion

In conclusion, forged large cylinders offer significant advantages over cast or machined alternatives. Their superior material properties, enhanced reliability, precise customization, and integration with modern manufacturing systems make them ideal for high-performance industrial and energy applications. Companies seeking dependable components for demanding operations benefit from the long-term durability, operational efficiency, and cost-effectiveness provided by forged large cylinders.

Manufacturers like Maiterio Group exemplify best practices in delivering high-quality forged components through advanced production systems, rigorous quality control, and a focus on long-term value. By selecting forged large cylinders, engineers and industrial leaders can ensure performance, safety, and reliability in critical applications.

Frequently asked questions (FAQ)

- What industries commonly use forged large cylinders? Energy, heavy machinery, oil and gas, transport, and construction sectors commonly rely on forged large cylinders due to their high strength and reliability.

- How does forging improve the properties of a large cylinder? Forging enhances the grain structure, reduces defects, and improves tensile strength, fatigue resistance, and toughness compared to other manufacturing methods.

- Can forged large cylinders be customized for specific applications? Yes, forging allows for near-net shapes, tailored dimensions, and material distribution to meet precise engineering requirements.

- What maintenance is required for forged large cylinders? Routine inspections for wear, cracks, and corrosion are recommended, but the superior material properties generally reduce maintenance frequency compared to other types.

- Why are forged large cylinders preferred over cast cylinders? They offer higher structural integrity, fewer defects, enhanced fatigue resistance, and improved operational longevity.

- How do manufacturers ensure the quality of forged large cylinders? Companies implement ISO-certified quality management, process control, testing, and precision machining to deliver consistent and reliable components.

English

English Español

Español русский

русский