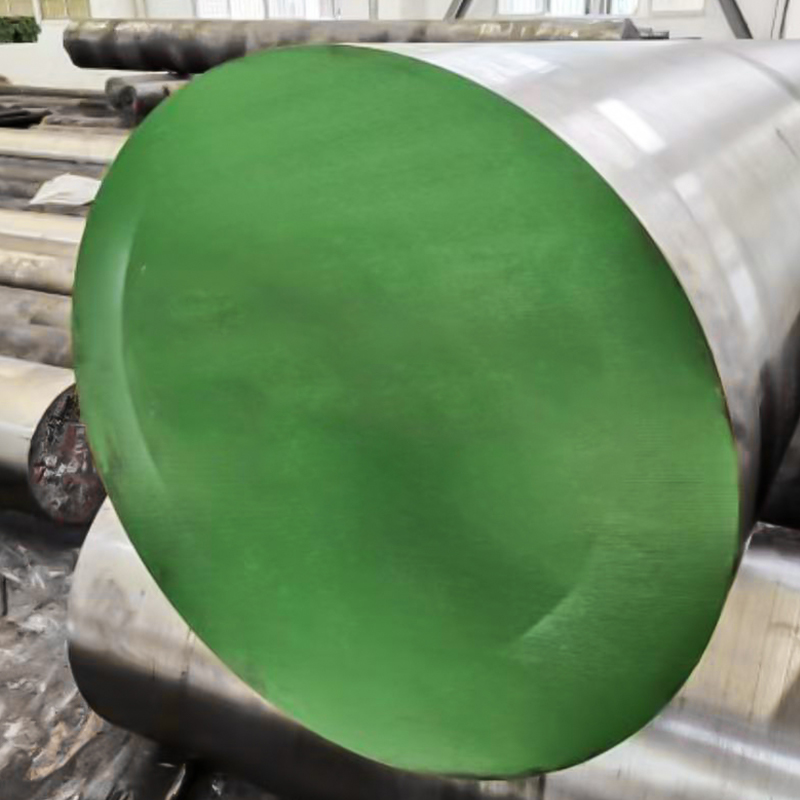

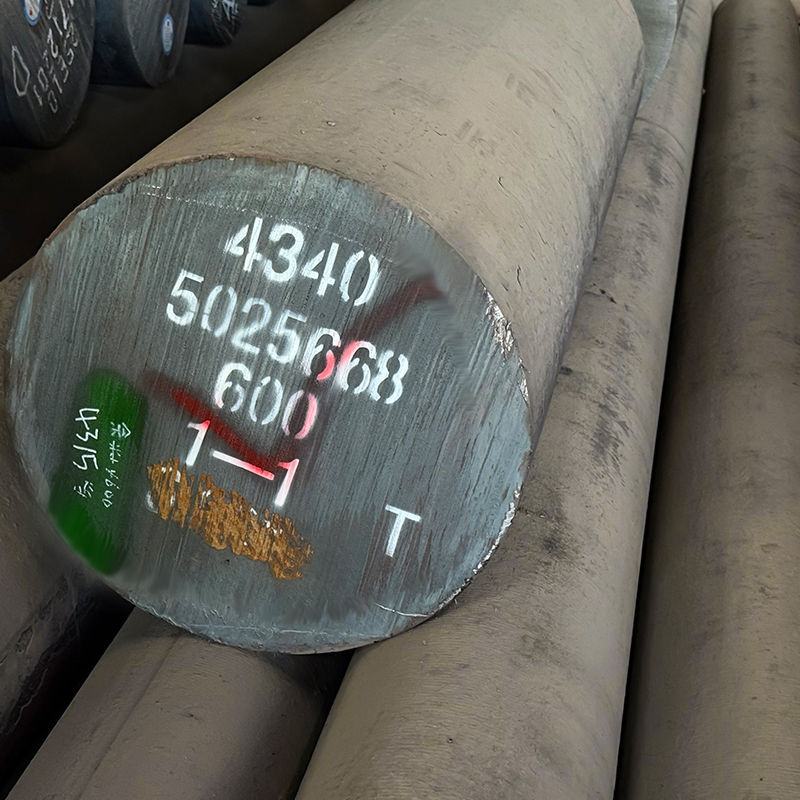

4340/EN24/817M40/40CrNi2Mo alloy steel

4340 (EN24 / 817M40 / 40CrNi2Mo) is a high-strength, low-alloy steel containing nickel, chromium, and molybdenum. It is known for its excellent toughness, fatigue resistance, and high tensile strength in both normalized and heat-treated conditions. This steel is widely used in aerospace, automotive, and heavy machinery applications where critical performance under high stress is required.

- Benefits

- Heat Treatment

- Applications

- Availability

- Parameter

English

English Español

Español русский

русский