Nickel-Based Alloy Round Bar Forgings Factory

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Nickel-based Alloy Steel Industry knowledge

Industry Insights on Nickel Based Alloy Round Bar Forgings

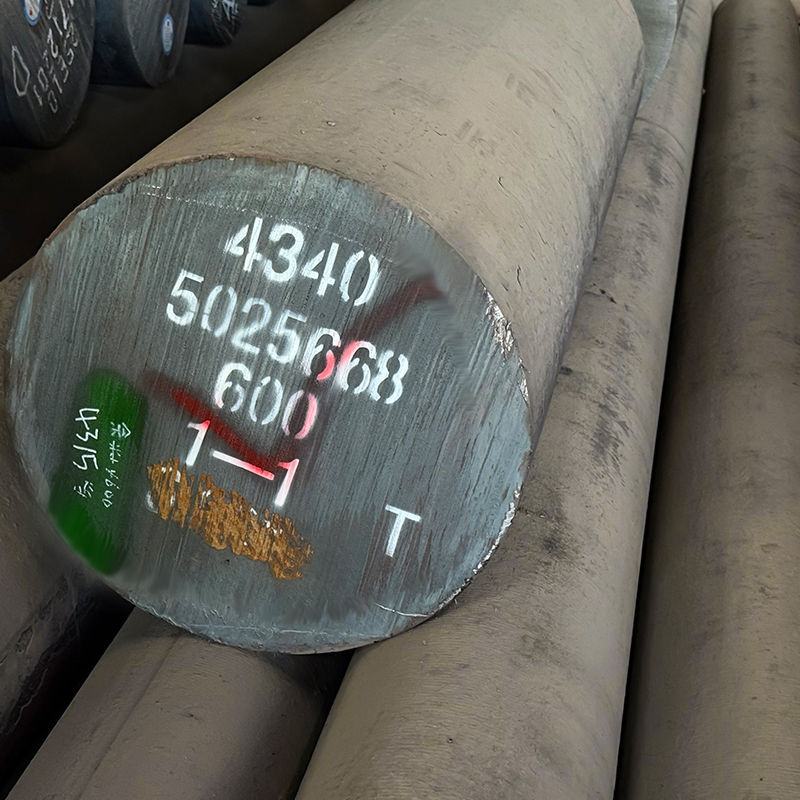

Nickel Based Alloy Round Bar Forgings are widely used in demanding industrial environments where high temperature strength corrosion resistance and structural reliability are required. Compared with conventional alloy steel or stainless steel materials nickel based alloys offer better performance stability under extreme service conditions.

Key Material Characteristics of Nickel Based Alloy Round Bar Forgings

Nickel based alloys use nickel as the primary matrix element and are alloyed with chromium molybdenum iron cobalt or niobium to achieve specific mechanical and chemical properties. These characteristics make forged round bars suitable for critical load bearing applications.

| Property | Description |

| High temperature strength | Maintains mechanical strength at elevated operating temperatures |

| Creep resistance | Suitable for long term service under continuous load |

| Corrosion resistance | Performs reliably in oil gas chemical and marine environments |

| Structural stability | Uniform grain structure after forging improves service life |

Why Forged Round Bars Are Preferred for High End Applications

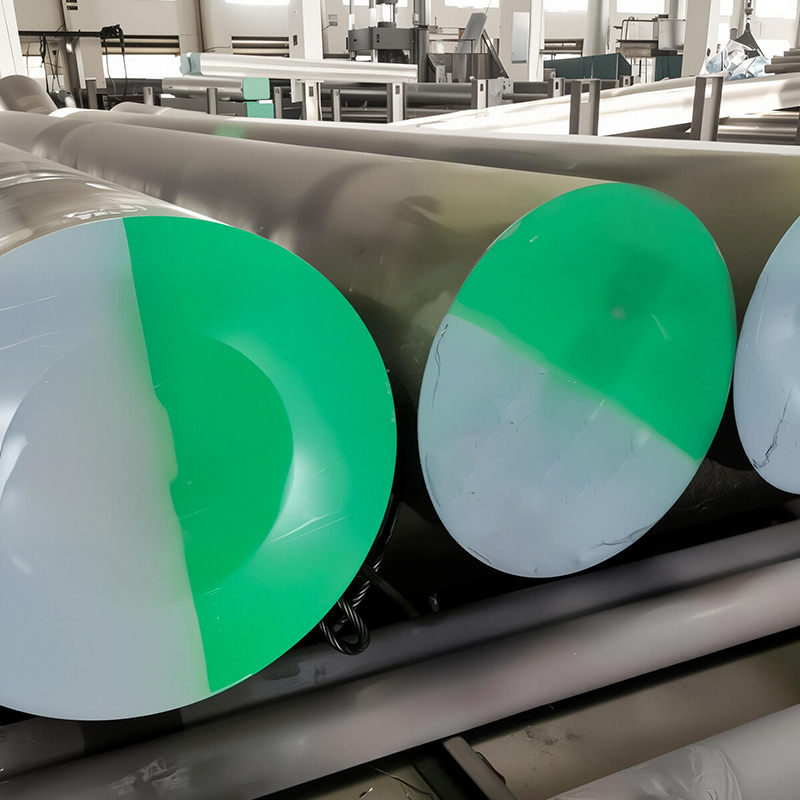

In many engineering projects forged round bars are selected instead of cast or rolled products. The forging process improves internal structure and reduces defects which is critical for safety related components.

Main advantages of forging

Forging refines grain structure increases density and improves fatigue resistance. It also ensures better consistency for subsequent machining processes.

Typical Application Industries

| Industry | Common applications |

| Oil and gas | Valve components shafts connectors pressure parts |

| Wind power | Main shafts structural connectors bearing components |

| Construction machinery | High load shafts transmission parts |

| Energy equipment | High temperature support and structural components |

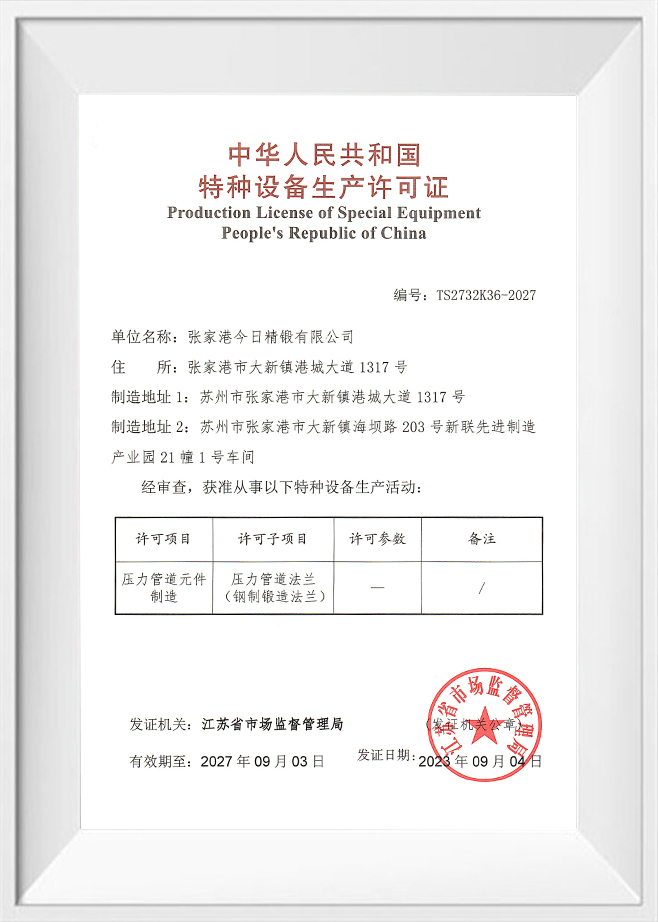

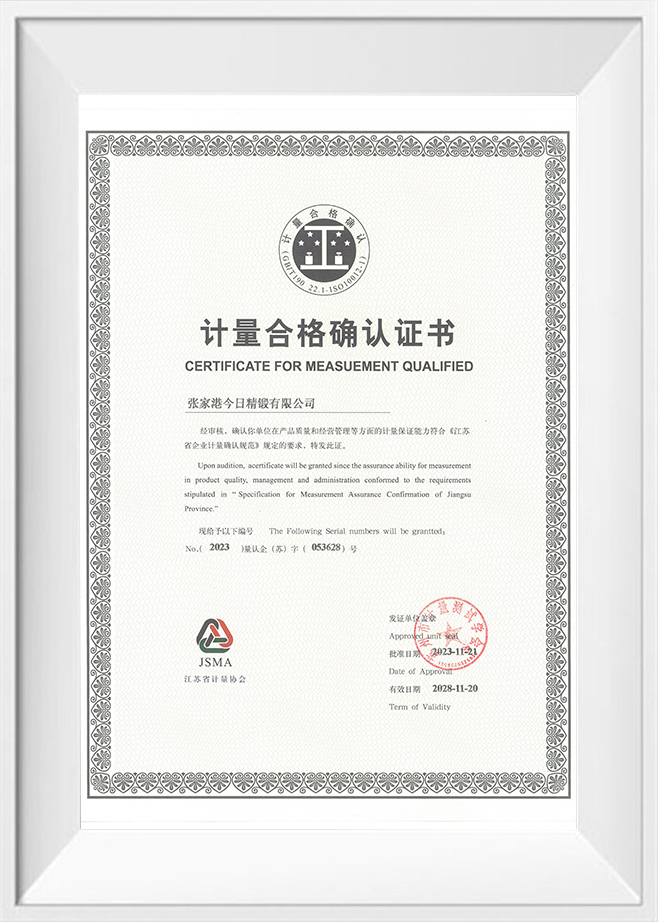

Zhangjiagang Maiterio Intelligent Equipment Company supplies nickel based alloy round bar forgings for a wide range of industrial applications supported by multiple forging lines and machining capacity.

Key Manufacturing Control Points for Nickel Based Alloy Round Bar Forgings

Producing nickel based alloy forgings requires strict process control to ensure consistent quality and mechanical performance.

Important manufacturing considerations

Forging temperature control is essential to avoid cracking or grain coarsening. Proper deformation ratios improve internal structure. Heat treatment must match alloy grade requirements. Dimensional control during forging helps improve machining efficiency.

Frequently Asked Questions

Can nickel based alloy round bar forgings be customized

Most industrial applications require customized diameters lengths and tolerances. Forged round bars are commonly produced according to customer specifications.

What is the difference between forged condition and heat treated delivery

Forged condition is suitable for customers performing their own heat treatment. Heat treated delivery helps reduce lead time for finished components.

Are nickel based alloys suitable for corrosive environments

With proper alloy composition and heat treatment nickel based alloys perform well in corrosive and high temperature conditions.

Does forging capability affect final product performance

Forging equipment scale process control and experience directly influence internal quality and long term reliability.

Industry Trend and Market Demand

As industrial equipment continues to operate under more demanding conditions the need for consistent and reliable nickel based alloy round bar forgings continues to grow. Manufacturers with stable forging capacity machining capability and long term industry experience are better positioned to support these requirements.

English

English Español

Español русский

русский