Alloy Steel Forgings Factory

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Alloy Steel Industry knowledge

The Ultimate Guide to Alloy Steel Forgings: Performance, Process, and Selection

In the world of high-performance industrial components, Alloy Steel Forgings represent a critical category of materials engineered for demanding applications. Defined as carbon steel enhanced with elements like chromium, nickel, and molybdenum, these forgings offer superior mechanical properties—including exceptional hardness, toughness, and wear resistance—that are precisely tailored through controlled heat treatment. This guide delves into the science, manufacturing, and strategic selection of alloy steel forgings, providing essential knowledge for engineers and procurement specialists in sectors like wind power, construction machinery, and oil & gas.

Understanding the Core: What Are Alloy Steel Forgings?

Alloy steel forgings are not merely steel; they are a metallurgical solution. By intentionally adding specific alloying elements to carbon steel, manufacturers can design materials with targeted performance characteristics. The forging process itself further enhances these properties by refining the metal's grain structure, creating parts with unparalleled integrity and reliability for critical applications.

| Key Alloying Element | Primary Contribution to Properties | Common Application Example |

|---|---|---|

| Chromium (Cr) | Increases hardness, wear resistance, and provides some corrosion resistance. | Bearings, gears, and shafts. |

| Molybdenum (Mo) | Enhances strength, especially at high temperatures, and improves hardenability. | High-pressure valves, power generation components. |

| Nickel (Ni) | Improves toughness and impact resistance, particularly at low temperatures. | Components for mining and heavy-duty off-road vehicles. |

| Vanadium (V) | Promotes fine grain structure, increasing strength and fatigue resistance. | High-stress automotive and tooling components. |

The Competitive Edge: Integrated Manufacturing and Supply Chain

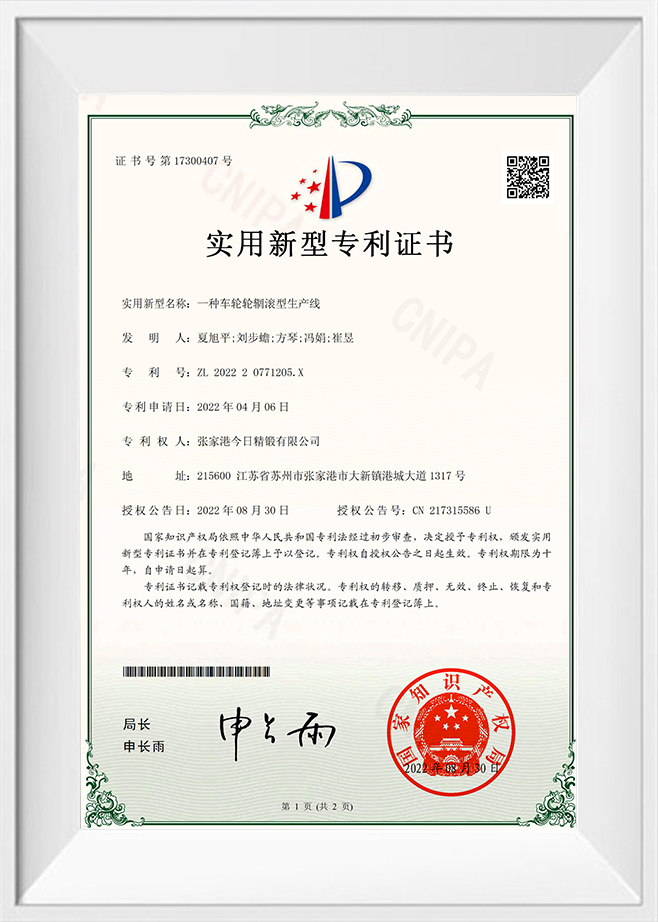

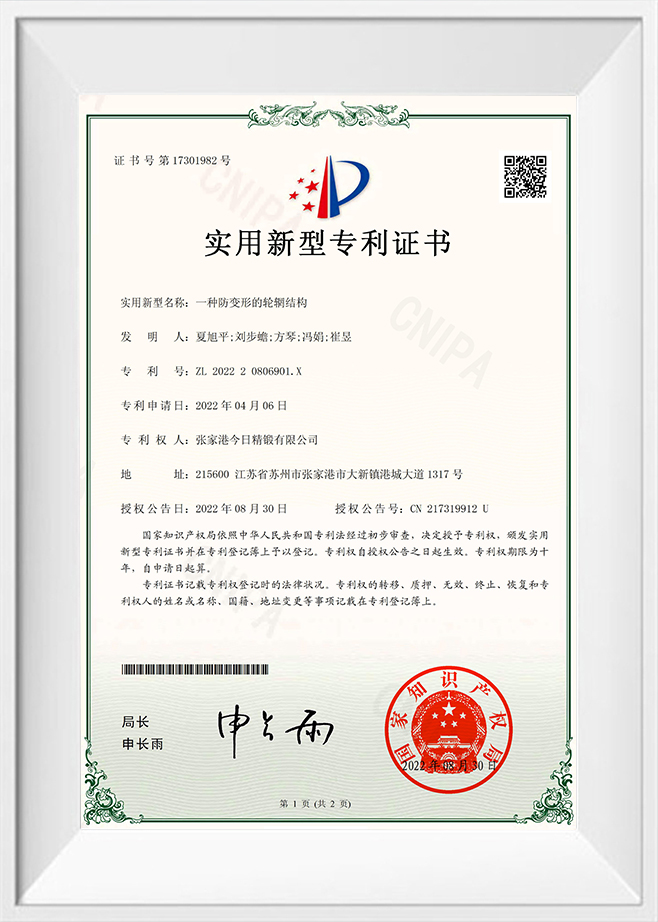

Leading manufacturers differentiate themselves through vertical integration and deep process mastery. For a supplier like Zhangjiagang Maiterio Intelligent Equipment Company, with 50,000 square meters of facility and over 30 years of founding team experience, the advantage is twofold:

- Supply Chain Control: As the largest customer of a top-tier alloy steel mill, such a manufacturer secures not only competitive raw material pricing but also guaranteed quality and consistency from the very beginning of the production chain.

- Process Innovation: Designing their own forging lines based on decades of user experience allows for optimization of critical parameters like forging allowance and production pace, directly translating to cost savings and higher precision for the end-user.

From Forging to Finish: The Alloy Steel Component Journey

The creation of a finished alloy steel part is a multi-stage journey that ensures final performance:

- Material Sourcing & Verification: Procuring alloy steel with verified chemistry from certified mills.

- Forging Process (Open-Die or Ring Rolling): Shaping the steel under immense pressure to align the grain flow and achieve the preliminary shape (e.g., seamless rolled rings, shafts, cylinders).

- Heat Treatment: Critical for achieving the desired mechanical properties (tensile strength, hardness, toughness) through controlled heating and cooling cycles.

- Precision Machining: Utilizing advanced CNC machining centers (70+ in a major facility) to achieve final net dimensions and surface finishes.

- Quality Assurance & Certification: Rigorous testing (NDT, mechanical testing) and documentation under ISO 9001, 14001, and 45001 frameworks for global acceptance.

FAQ

What are the main advantages of alloy steel forgings over standard carbon steel forgings?

The primary advantages are enhanced and tailorable mechanical properties. While carbon steel offers good basic strength, alloy steels add elements like chromium, molybdenum, and nickel to provide:

- Higher tensile and yield strength.

- Better impact resistance and toughness, especially in challenging environments.

- Superior wear resistance and hardness.

- Improved response to heat treatment, allowing properties to be fine-tuned for specific applications.

This makes them essential for high-stress parts in wind turbine gearboxes, construction machinery joints, and critical power transmission systems.

How does the heat treatment process affect the final properties of an alloy steel forging?

Heat treatment is a transformative, non-negotiable step for alloy steels. It involves precisely controlled heating and cooling cycles to manipulate the steel's internal microstructure. Common processes include:

- Quenching and Tempering: Provides an excellent balance of high strength and good toughness, widely used for gears and shafts.

- Normalizing: Refines the grain structure for more uniform properties throughout the forging.

- Annealing: Softens the steel to improve machinability or relieve internal stresses.

The specific treatment is chosen based on the alloy composition and the final performance requirements of the part.

What industries most commonly use alloy steel forgings and why?

Alloy steel forgings are the material of choice for industries where component failure is not an option due to extreme stress, wear, or environmental conditions:

| Industry | Typical Components | Key Property Requirement |

|---|---|---|

| Wind Power | Main shafts, gearbox gears, bearing rings | High fatigue strength, impact toughness |

| Oil & Gas | Valve bodies, wellhead equipment, drill string tools | High strength, corrosion & sour service resistance |

| Construction Machinery | Undercarriage parts, pivot shafts, hydraulic components | Extreme wear resistance, high yield strength |

| Power Generation | Turbine blades, generator shafts | High-temperature strength, creep resistance |

What does "seamless rolled ring forging" mean and what are its benefits?

Seamless rolled ring forging is a specialized process where a pierced doughnut-shaped preform is rolled under pressure to expand its diameter and refine its grain structure into a continuous ring. Key benefits include:

- Superior Strength: The grain flow is contoured to the ring's shape, providing optimal mechanical properties in the circumferential direction.

- Material Efficiency: It minimizes waste compared to machining a ring from a solid block.

- Structural Integrity: Being seamless, it has no welded joints that could be potential points of failure under cyclic loads, making it ideal for bearing races, flanges, and turbine components.

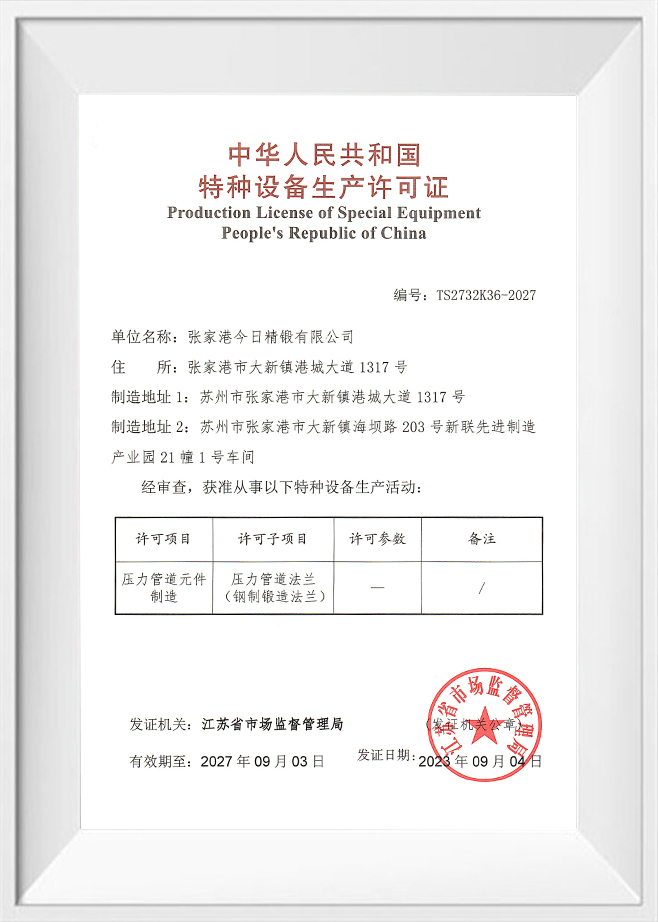

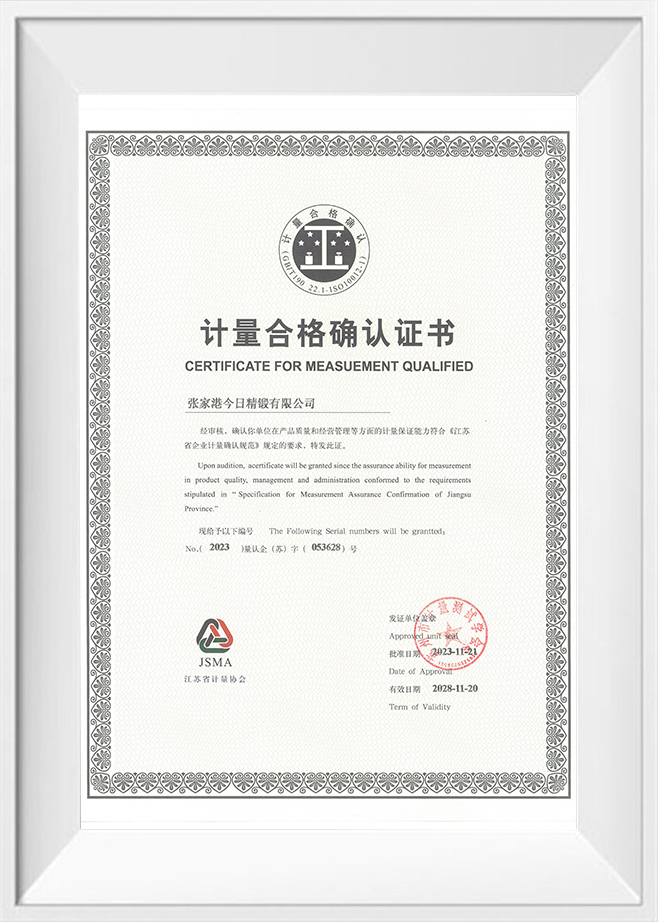

What quality certifications and tests are crucial when sourcing alloy steel forgings?

To ensure reliability and global acceptance, a reputable supplier must adhere to:

- International Standards: ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and often industry-specific codes (e.g., API, ASTM).

- Material Traceability: Complete documentation from the steel mill's melt report through to the final part (Heat Number traceability).

- Comprehensive Testing: This includes chemical analysis, mechanical property testing (tensile, impact), and Non-Destructive Testing (NDT) like Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI) to detect internal and surface flaws.

English

English Español

Español русский

русский