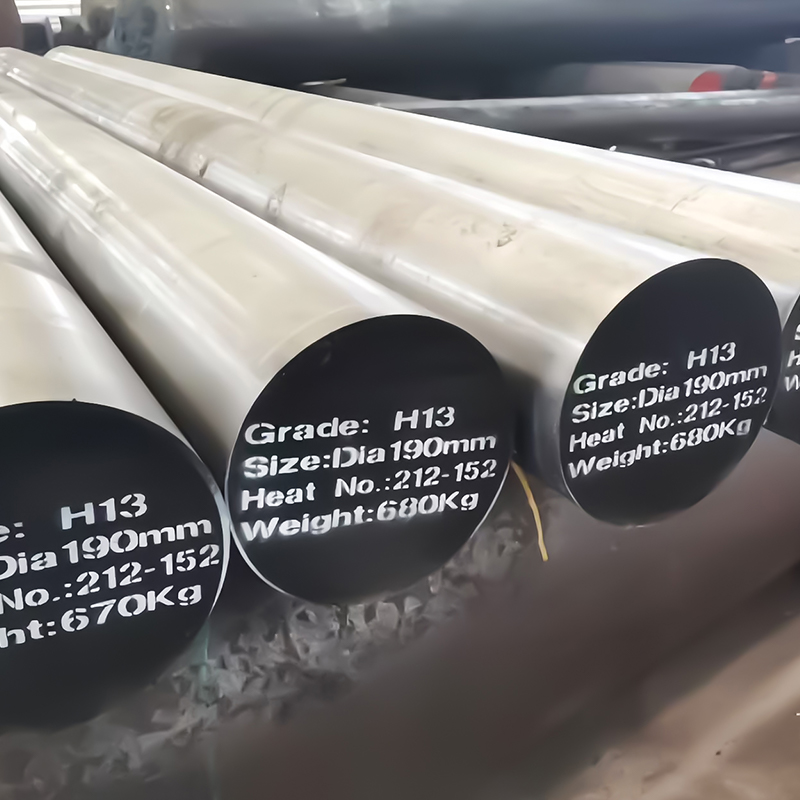

H13/X40CrMoV5-1/4Cr5MoSiV1 alloy steel

H13/X40CrMoV5-1/4Cr5MoSiV1 is a high-performance hot-work tool steel, renowned for its exceptional toughness, high-temperature strength, and resistance to thermal fatigue. It is widely used in die-casting, forging, and plastic molding industries for tooling and other high-stress, high-temperature applications.

- Benefits

- Heat Treatment

- Applications

- Availability

- Parameter

English

English Español

Español русский

русский