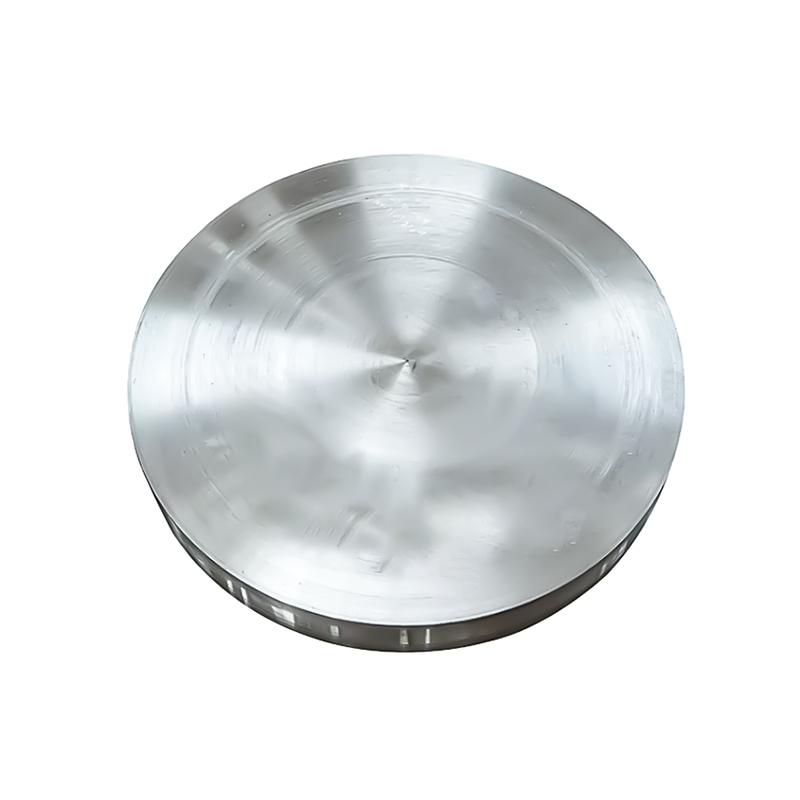

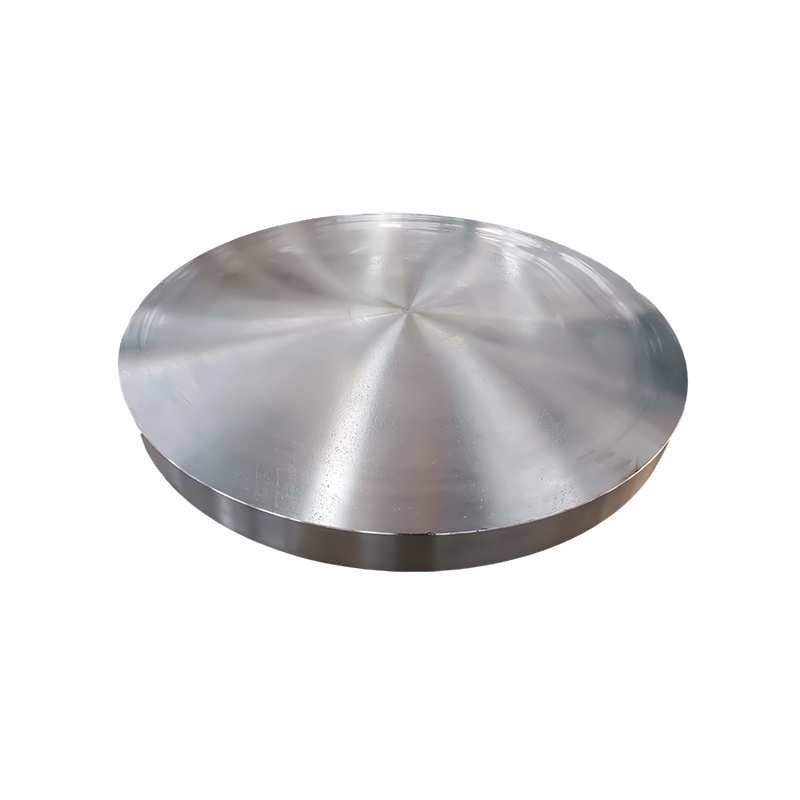

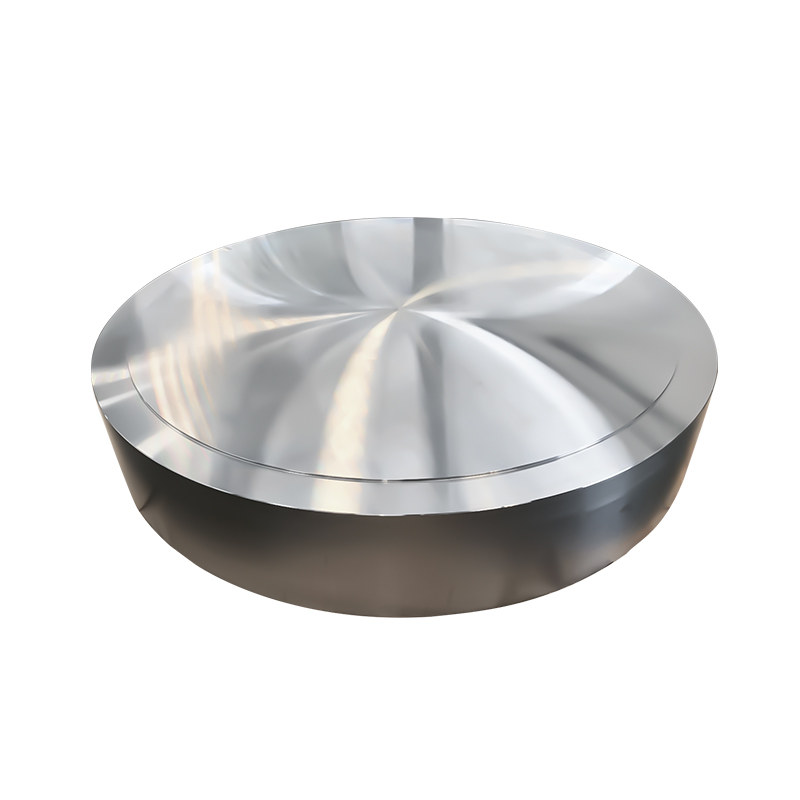

Forged Gears/Discs Suppliers

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Forged Gears/Discs Industry knowledge

Why Forged Discs Offer Superior Load Capacity Over Castings or Plate-Cut Sections in Large Module Industrial Gears

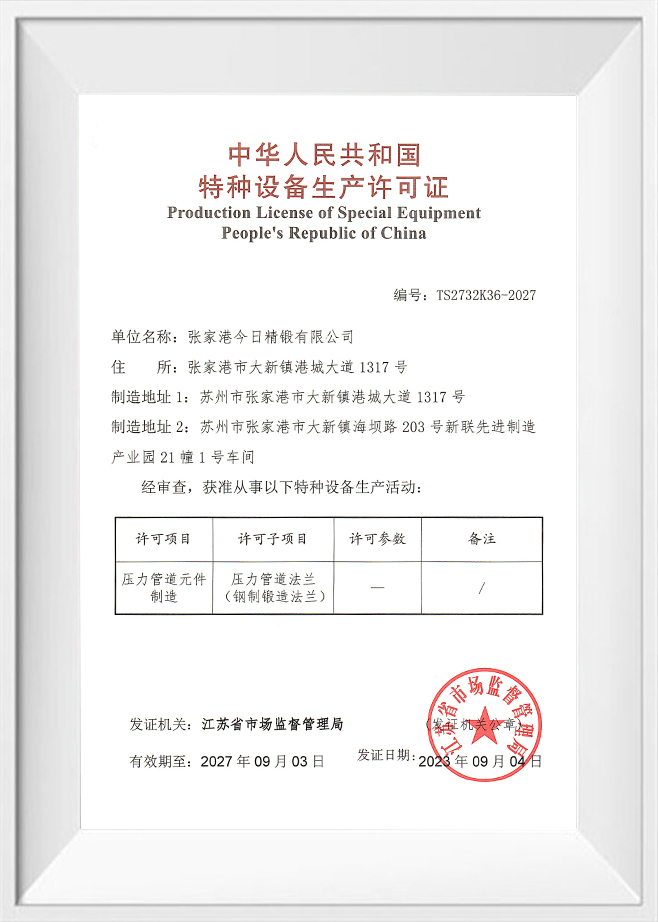

In heavy-duty industrial machinery, wind power, and mining equipment, large module gears are the core transmission components. Selecting Forged Discs as gear blanks, rather than castings or plate-cut sections, is the technical key to ensuring high load-carrying capacity and extremely long fatigue life. Zhangjiagang Maiterio Intelligent Equipment Company leverages its integrated manufacturing advantages to provide world-class forging solutions.

Core Reasons Why Forged Discs are Preferred for High-Performance Gears

1. Breaking Down Cast Structures and Eliminating Defects

- Forging Process: Massive pressure breaks down coarse grains in the steel ingot and welds internal shrinkage and gas pores. Zhangjiagang Maiterio Intelligent Equipment Company, with 30 years of industry heritage, utilizes its 2 open-die and 3 ring forging lines to ensure an extremely dense metal structure.

- Castings/Plates: Castings often contain micro-blowholes, while plates may suffer from laminar segregation. Under heavy torque, these defects become crack initiation points, leading to gear tooth failure.

2. Perfect Fiber Orientation (Grain Flow)

In large module gears, the root of the tooth bears the maximum bending stress. Forged discs utilize the upsetting process to ensure metal grain flow is distributed uniformly in a radial pattern.

- Advantage: Once the gear teeth are machined, the metal grain flow remains parallel to the tooth profile, providing the highest possible impact toughness.

- Comparison: Plate-cut sections have unidirectional grain flow. This means at certain angles of the gear, the grain flow is cut, creating structural weak points.

3. Performance Gains from Full Supply Chain Control

As the largest customer of Yong Gang (a top 3 alloy steel mill in China), Zhangjiagang Maiterio Intelligent Equipment Company ensures raw material purity from the source. Cleaner steel leads to a more uniform hardened layer depth during the heat treatment of Forged Gears/Discs, directly enhancing the load capacity of the gear tooth surface.

In-Depth Performance Comparison

| Key Metric | Forged Discs | Castings | Plate Cutting |

| Structural Density | Extremely High (Pressure-closed defects) | Low (Prone to pores/porosity) | Moderate (Anisotropic properties) |

| Fatigue Life | 100% (Baseline) | 50% - 60% | 70% - 80% |

| Low-Temp Impact Toughness | Excellent (For extreme conditions) | Poor (Prone to brittle fracture) | Average |

| Machining Allowance | Extremely Small (Maiterio optimized) | Large | Extremely Large (High scrap waste) |

| Core Terminal Applications | Vestas, Caterpillar, Komatsu | Low-end machinery | General structural parts |

FAQ

Q1: How does Zhangjiagang Maiterio Intelligent Equipment Company ensure price competitiveness for large gear forgings?

A: In 2024, we expanded into steel trading. As Yong Gang's largest buyer, we secure the most competitive raw material prices and perform internal quality secondary checks. Furthermore, Zhangjiagang Maiterio Intelligent Equipment Company designs its own forging lines, achieving smaller machining allowances than industry peers. This significantly reduces our customers' time and material costs during the precision machining stage.

Q2: Why do global giants like GE Vernova and Siemens Energy choose Maiterio's disc forgings?

A: It comes down to the combination of a rigorous quality system and decades of experience. We hold ISO 9001/14001/45001 certifications and our founding team has over 30 years of industry leadership. Our 50,000 sqm facility is equipped with over 70 CNC machines, providing a one-stop solution from raw forging to high-precision finished Forged Gears/Discs that meet the most stringent performance requirements of global energy leaders.

Q3: What practical value does Maiterio's "Forging Whole-Line Solution" offer to customers?

A: Based on 30 years as "users" of forging lines, Zhangjiagang Maiterio Intelligent Equipment Company developed its third business sector: Whole-line Solutions. We know exactly how to design a production line to maximize efficiency. For our customers, this means every forging we supply is produced via an optimized path, ensuring higher production cadences and superior quality stability, helping them maintain a technical edge in competitive markets.

English

English Español

Español русский

русский