Stainless Steel Bar Forgings Factory

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Stainless Steel Industry knowledge

Stainless Steel Bar Forgings Manufacturing Principles Material Selection and Industrial Applications

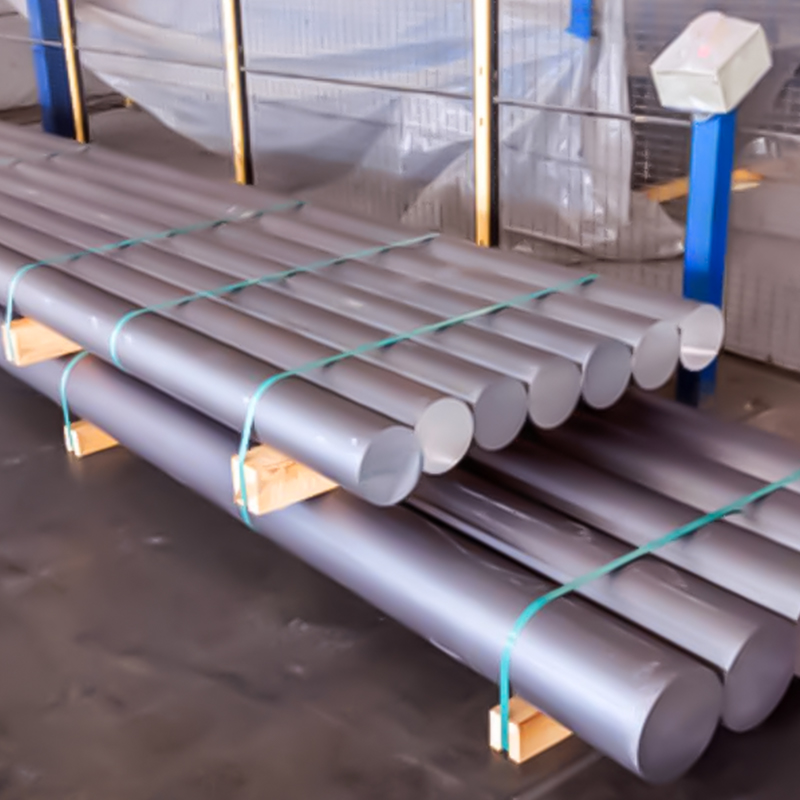

Stainless steel bar forgings are widely used in industries where mechanical strength structural integrity and corrosion resistance are required at the same time Compared with rolled or cast bars forged stainless steel bars provide a refined grain structure and improved load bearing performance This makes them suitable for critical components operating under high stress or harsh working environments

What Are Stainless Steel Bar Forgings

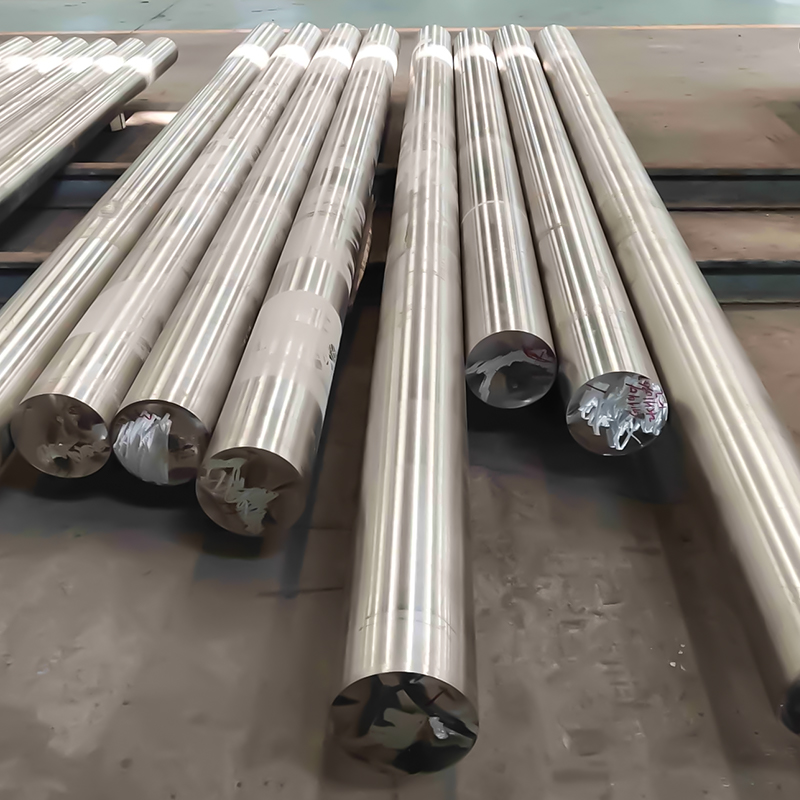

Stainless steel bar forgings are produced by applying compressive force to heated stainless steel billets through ring forging or open die forging processes During forging the internal metal flow follows the bar shape which helps eliminate internal defects and improves directional strength

Compared with conventional stainless steel bars forged bars usually offer higher fatigue resistance improved impact toughness more uniform microstructure and more stable performance under dynamic loads These advantages are especially important for long term industrial use

Common Stainless Steel Grades Used in Bar Forgings

Different working conditions require different stainless steel materials The table below shows commonly forged stainless steel grades and their typical applications

| Stainless Steel Grade | Main Properties | Typical Applications |

|---|---|---|

| 304 and 304L | Good corrosion resistance easy machining | General machinery shafts structural components |

| 316 and 316L | Improved resistance to corrosion and chemicals | Oil and gas equipment marine components |

| 410 and 420 | High strength moderate corrosion resistance | Mechanical parts tool components |

| 17 4PH | High strength after heat treatment | Wind power components high load shafts |

| Duplex Stainless Steel | High strength and corrosion resistance | Energy offshore pressure components |

Forging Processes for Stainless Steel Bars

Open Die Forging

Open die forging is suitable for large diameter or custom size stainless steel bars It allows flexible production and precise control of metal flow direction which is important for heavy duty industrial parts

Ring Forging

Ring forging is used for specific bar or hollow profiles This process creates a dense internal structure and consistent mechanical properties It is commonly used for large industrial components that require long service life

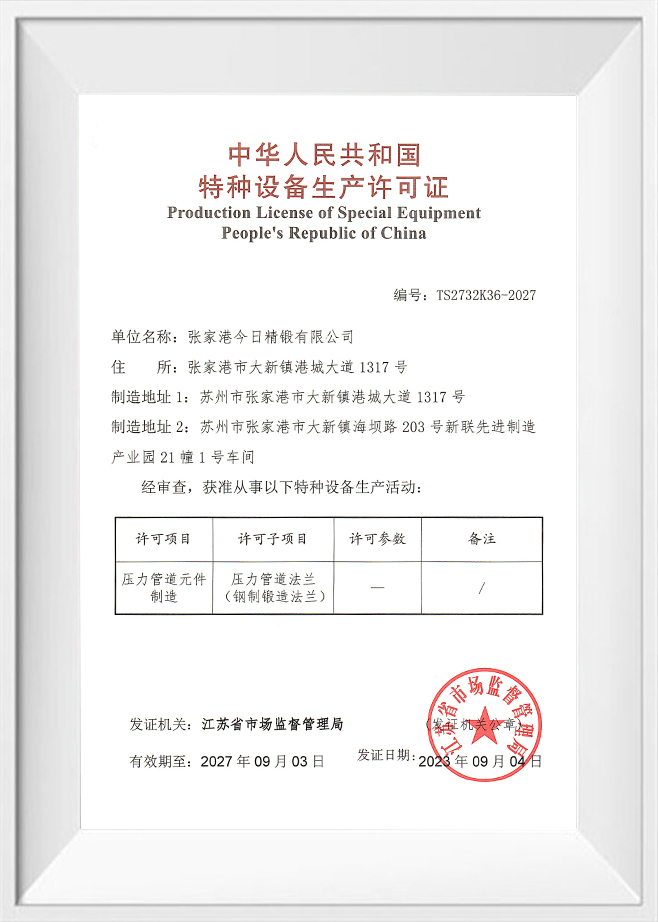

Manufacturers with multiple forging lines and integrated CNC machining workshops are able to control dimensional accuracy and delivery stability more effectively

Performance Advantages of Forged Stainless Steel Bars

Forging aligns the grain flow along the length of the bar which improves mechanical performance under bending torsion and repeated loads Forged stainless steel bars generally show longer fatigue life lower risk of internal defects and more predictable behavior after heat treatment

These advantages are critical for applications in wind power construction machinery and oil and gas industries

Typical Industrial Applications

Stainless steel bar forgings are commonly used in wind power systems construction machinery oil and gas equipment and heavy industrial machinery Components include shafts pins bearing seats valve stems and structural bars where reliability is required

Quality Control and Machining Considerations

After forging stainless steel bars usually undergo heat treatment ultrasonic testing and CNC machining to meet final specifications Stable material structure helps ensure consistent machining accuracy especially for OEM and customized projects

Manufacturers such as Zhangjiagang Maiterio Intelligent Equipment Company combine forging capacity with in house machining which helps reduce outsourcing risks and improve overall quality control

Frequently Asked Questions

What size range is available for stainless steel bar forgings

Forged stainless steel bars can be produced in various diameters and lengths depending on equipment capacity and project requirements Custom sizes are commonly supported

Are forged stainless steel bars suitable for high temperature environments

Yes Certain grades such as 316 17 4PH and duplex stainless steel maintain stable mechanical properties under elevated temperatures

Can forged bars be supplied in rough forged or machined condition

Both supply conditions are available Rough forged bars allow flexible machining while fully machined bars help reduce downstream processing time

Does forging affect corrosion resistance

Forging improves internal density and does not negatively affect corrosion resistance when proper material selection and heat treatment are applied

Conclusion

Stainless steel bar forgings provide a reliable solution for demanding industrial applications Through appropriate material selection controlled forging processes and precision machining forged stainless steel bars support long term performance across energy heavy machinery and infrastructure industries

For OEM buyers and project based sourcing working with manufacturers that integrate forging and machining capabilities helps ensure consistency traceability and stable supply throughout the product lifecycle

English

English Español

Español русский

русский