Mining Machinery Forgings Suppliers

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Mining Machinery Industry knowledge

What Are the Key Considerations in Mining Machinery Forgings for Optimal Performance?

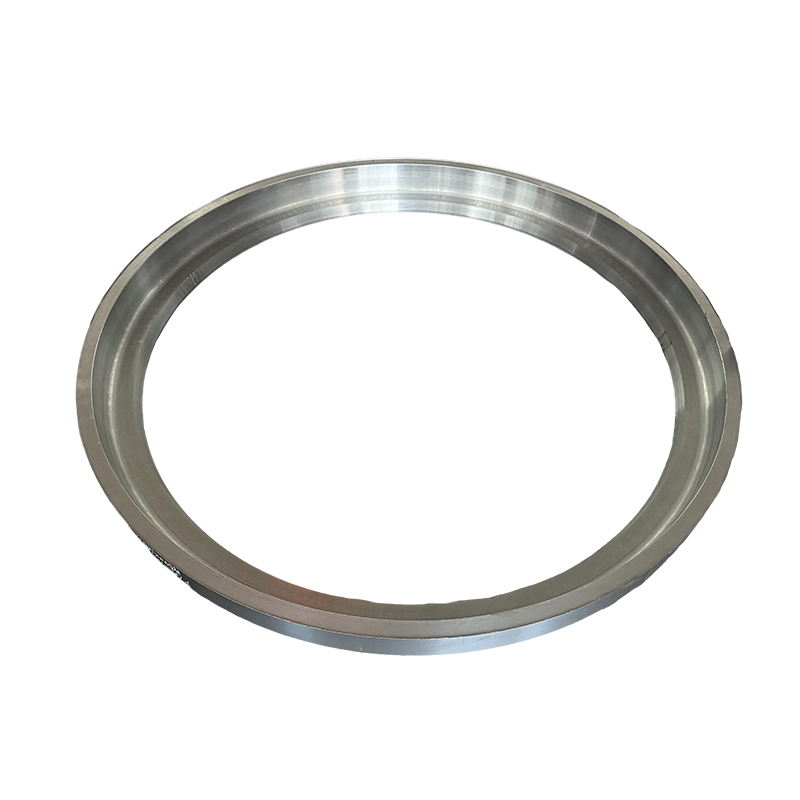

Mining machinery forgings are an essential component in the production and operation of equipment used in the mining industry. These forgings, including shafts, gears, and bearings, play a crucial role in the durability, strength, and efficiency of machinery.

The Importance of Mining Machinery Forgings

Mining machinery operates under extremely harsh conditions, including high pressure, heavy loads, abrasive materials, and extreme temperatures. Forged components are preferred in these applications due to their superior mechanical properties, which include enhanced strength, toughness, and resistance to wear. Unlike cast components, forgings have a fine-grained structure, which provides greater resistance to fatigue and stress, making them ideal for the demanding requirements of mining operations.

Key Types of Mining Machinery Forgings

Mining machinery forgings come in a variety of forms, each tailored to meet the specific needs of different types of equipment. These include:

-

Forged Shafts

Shafts are fundamental components used in various mining machines such as crushers, grinders, and conveyors. They must withstand rotational forces, impact loads, and torque. Forged shafts ensure higher tensile strength and fatigue resistance compared to cast shafts. -

Forged Gears

Gears used in mining machinery require high precision and durability, as they transfer motion and force within machines. Forged gears are made from high-strength steel or alloy materials, ensuring they can endure the stresses involved in the transmission of power in crushers, mills, and other heavy equipment. -

Forged Cylinders

Hydraulic cylinders used in mining machinery need to operate smoothly under extreme conditions. Forged cylinders provide enhanced strength and resistance to wear, making them capable of performing in harsh environments, such as those found in digging and material handling equipment. -

Forged Bearings

Bearings play a critical role in minimizing friction and supporting rotating parts in mining machinery. Forged bearings are typically more reliable than cast bearings, offering better resistance to wear, high-temperature performance, and enhanced load-bearing capabilities.

Key Considerations in Mining Machinery Forgings

When manufacturing mining machinery forgings, there are several critical factors to consider to ensure optimal performance and longevity of the components:

1. Material Selection

The choice of material significantly affects the performance of the forged components. In mining machinery, materials like high-carbon steels, alloy steels, and tool steels are commonly used. These materials are selected based on their ability to resist wear, corrosion, and impact. Alloying elements such as chromium, nickel, and vanadium are often added to enhance properties such as toughness, strength, and resistance to corrosion.

2. Forging Process

The forging process is central to achieving the desired mechanical properties of the component. It involves heating the metal to a specific temperature and then shaping it using compressive forces. There are two primary types of forging processes:

- Open Die Forging: In open die forging, the metal is placed between two flat dies, which compress it to the desired shape. This method is suitable for large, simple components like shafts and cylinders.

- Closed Die Forging: Also known as impression die forging, this process involves the use of dies with cavities that shape the metal into a more complex form. Closed die forging is ideal for components like gears and bearings, where precision and intricate shapes are required.

3. Heat Treatment

After forging, heat treatment processes such as quenching, tempering, and annealing are applied to improve the hardness, strength, and toughness of the components. For example, gears and shafts are often heat-treated to achieve the necessary hardness to resist wear and deformation during operation.

4. Precision Machining

Once the components are forged and heat-treated, they often undergo precision machining to achieve the required dimensions and surface finish. This step ensures that the parts will fit correctly in the machinery and operate efficiently. CNC machining, turning, and milling are commonly used to meet the tight tolerances needed for high-performance mining machinery components.

5. Quality Control and Testing

To ensure the reliability and longevity of mining machinery forgings, rigorous quality control measures are essential. At Zhangjiagang Maiterio Intelligent Equipment Company, all forgings undergo thorough inspection using state-of-the-art testing equipment. This includes:

- Ultrasonic Testing: To detect internal defects or voids in the forgings.

- X-ray Inspection: To assess the structural integrity and identify any cracks or other flaws.

- Hardness Testing: To ensure the material meets the required hardness specifications.

- Dimensional Inspection: To verify that the parts meet precise size and geometry requirements.

This comprehensive testing process ensures that each forged component meets the highest standards of quality and performance.

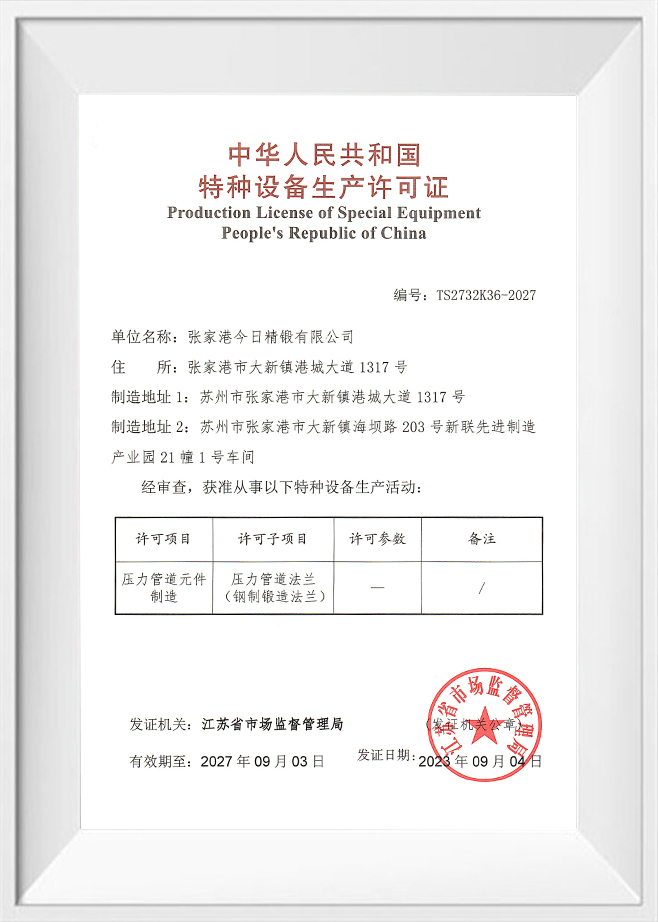

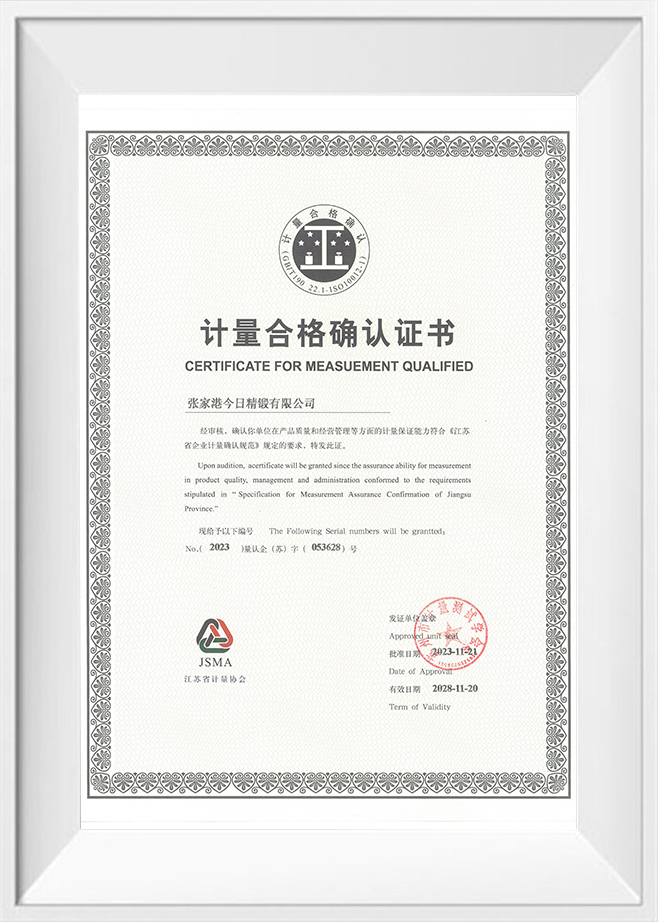

The Role of Advanced Forging Technology in Mining Machinery Performance

Zhangjiagang Maiterio Intelligent Equipment Company specializes in providing high-performance mining machinery forgings, such as seamless rolled rings, forged shafts, forged cylinders, and precision-machined components. Their manufacturing process adheres to ISO 9001, 14001, and 45001 standards, ensuring that the quality of the products is consistent with global benchmarks.

By focusing on integrating design, manufacturing, and service, Zhangjiagang Maiterio builds a streamlined and collaborative system that enhances raw material sourcing, production efficiency, and final delivery. The company’s emphasis on cross-industry collaboration and respect for the craftsmanship at every stage of production contributes to its standing as an industry leader.

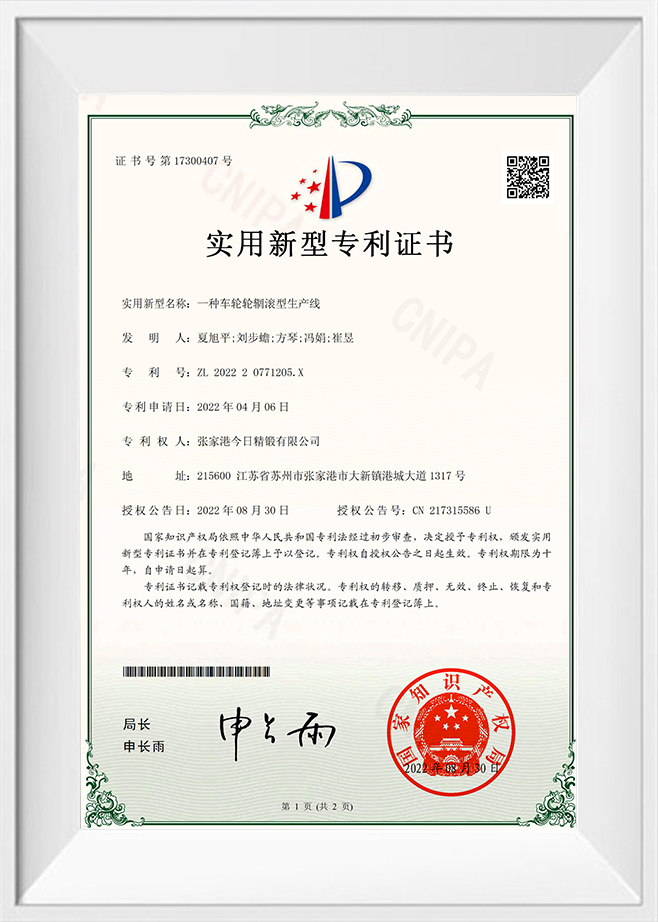

The company’s technical excellence is further evidenced by its engineers, who have been recognized with provincial-level awards for innovation and technological advancement. Their contributions have led to significant breakthroughs in forging die design, process efficiency, and product performance, further cementing Maiterio’s reputation as a pioneer in technology-driven manufacturing.

Conclusion

Mining machinery forgings play an indispensable role in the durability and performance of equipment used in mining operations. By selecting appropriate materials, employing precise forging and heat treatment processes, and adhering to strict quality control procedures, Zhangjiagang Maiterio Intelligent Equipment Company ensures that its mining machinery components meet the stringent requirements of the industry. With advanced technology, high-quality materials, and a commitment to innovation, these forgings continue to support the mining industry’s pursuit of efficiency, productivity, and safety.

English

English Español

Español русский

русский