Engineering Machinery Forgings Suppliers

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Engineering Machinery Industry knowledge

How Does the Forging Process Enhance the Strength of Engineering Machinery Components?

Engineering machinery forgings are critical components used in various heavy-duty machinery, ranging from construction equipment to energy generation systems. They play a pivotal role in enhancing the durability, reliability, and performance of complex machinery.

Understanding Engineering Machinery Forgings

Engineering machinery forgings refer to components made by shaping metal under high pressure through various forging processes. This method significantly improves the material’s strength and fatigue resistance compared to casting or machining from solid blocks. Forged parts have more refined grain structures and a higher overall integrity, making them indispensable in heavy-duty machinery.

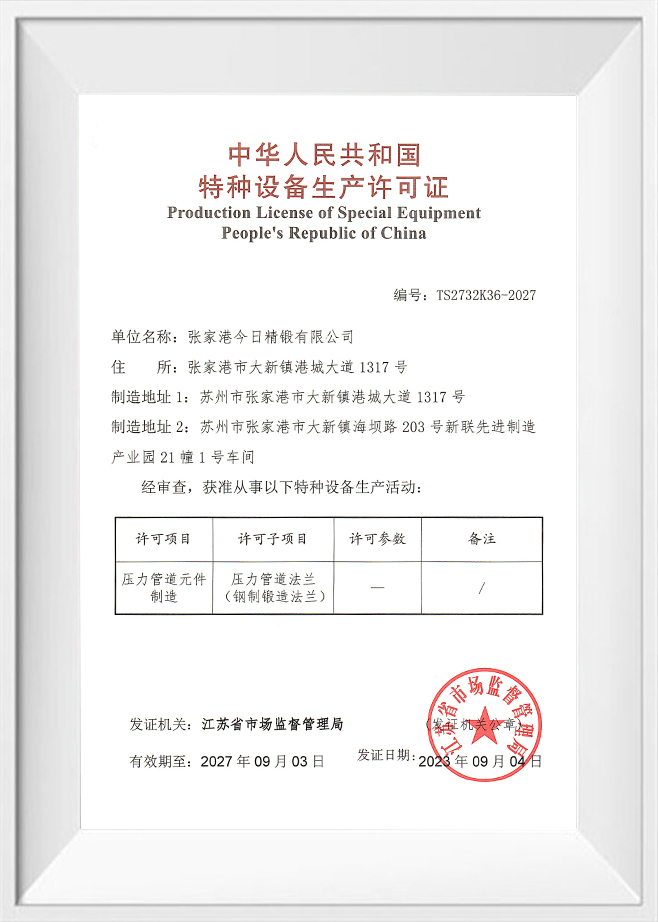

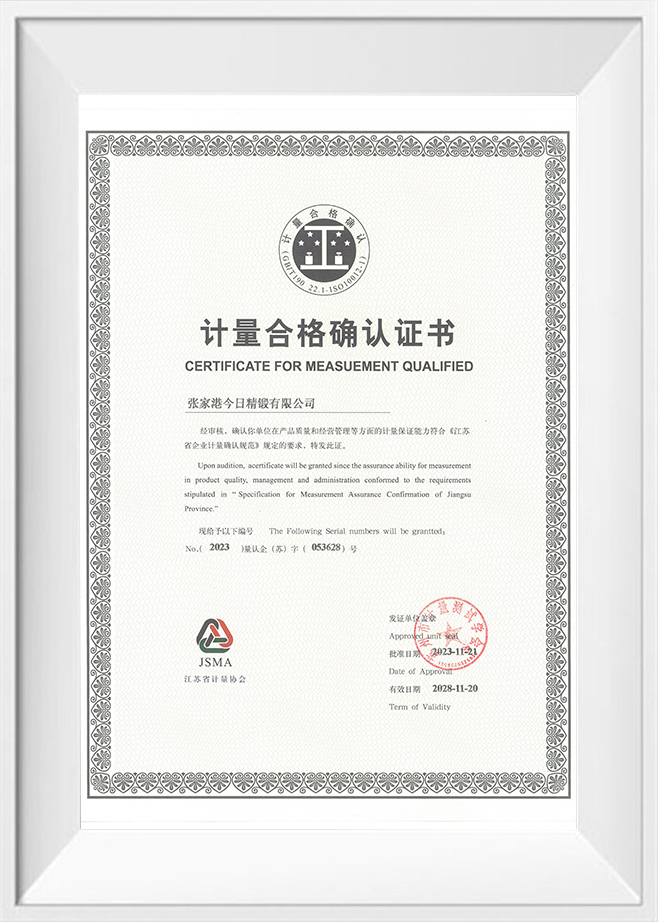

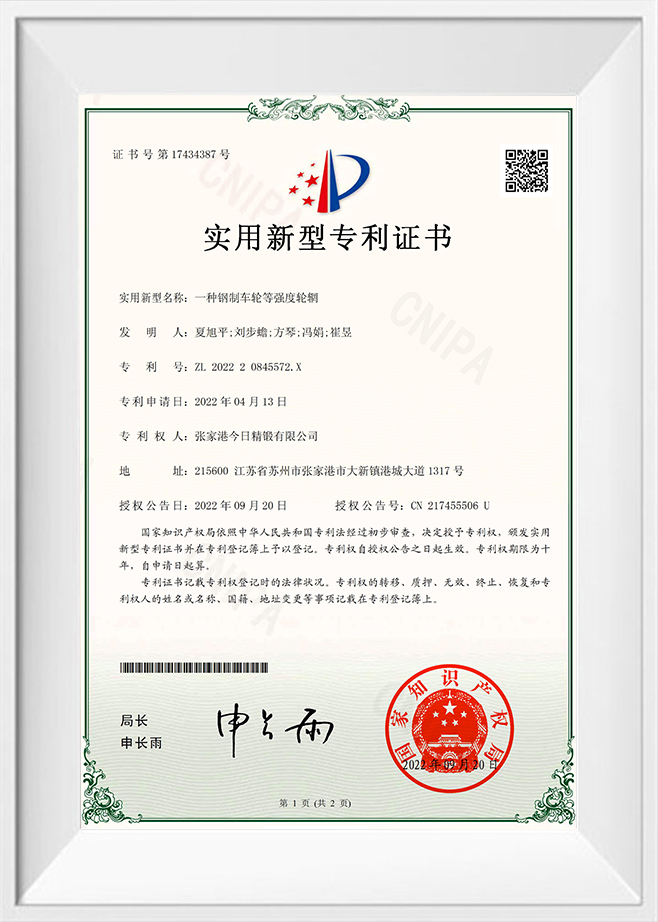

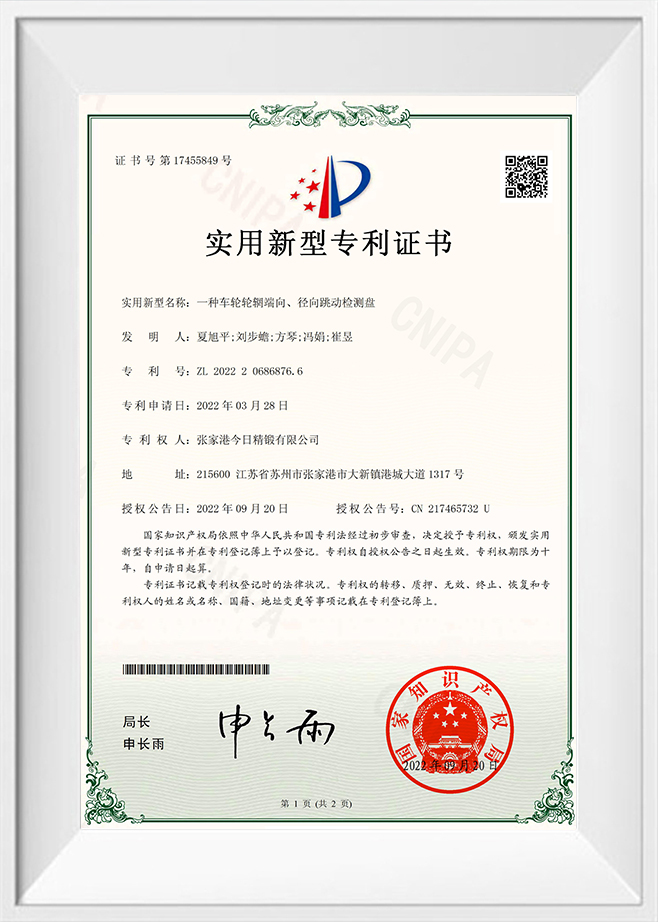

At Zhangjiagang Maiterio Intelligent Equipment Company, the company produces a wide range of high-performance forgings, including seamless rolled rings, forged shafts, and cylinders. These products are meticulously crafted to meet the highest quality standards, backed by certifications such as ISO 9001, 14001, and 45001.

The Forging Process: A Step-by-Step Overview

The forging process can be broken down into several key stages, which ensure the final part meets stringent mechanical properties and performance requirements.

1. Material Selection

The first step in the forging process involves selecting the right material. For engineering machinery forgings, alloy steels, carbon steels, and stainless steels are commonly used due to their excellent mechanical properties.

2. Preforming

During preforming, a hollow circular preform is prepared to create seamless rings. This step is crucial for achieving parts with uniform thickness and a smooth surface, which directly affects the quality and strength of the final product.

3. Heating and Shaping

The preform is heated to a specific temperature, softening the material for easier shaping. Using powerful hydraulic presses or forging hammers, the preform is then shaped into the desired geometry. This process creates parts with a radial grain flow, which is vital for improving the material’s strength in the circumferential direction. Parts forged with radial grain flow offer enhanced performance and higher fatigue resistance.

4. Cooling and Finishing

After the material is shaped, it is allowed to cool. The cooling rate can be controlled to ensure the final product meets the desired hardness and toughness. The component is then finished through processes like machining, grinding, and heat treatment to meet the required dimensional accuracy.

Characteristics of Engineering Machinery Forgings

The unique characteristics of engineering machinery forgings make them suitable for a wide range of heavy-duty applications. These characteristics include:

- Superior Strength: Forged parts have a high strength-to-weight ratio, making them suitable for high-load-bearing applications.

- Enhanced Durability: The forging process refines the material’s grain structure, improving fatigue resistance, which is essential for parts that undergo continuous stress.

- Improved Material Yield: Forgings typically offer better material yield compared to castings, reducing waste and ensuring better utilization of raw materials.

- Dimensional Accuracy: Forged parts exhibit higher dimensional accuracy, reducing the need for extensive post-processing.

Applications of Engineering Machinery Forgings

Engineering machinery forgings are essential in a variety of applications where strength, precision, and reliability are critical. Some of the primary applications include:

- Bearing Races: The rolling element bearings used in heavy machinery require high-strength forged rings to ensure smooth operation and extend service life.

- Gear Rings: Forged gear rings are used in power transmission systems, offering durability and load-bearing capacity.

- Turbine Support Structures: In power generation systems, forged components are used to support turbines and other critical machinery parts, where reliability is paramount.

- Flanges for Wind Towers: Forged flanges are used in wind towers, withstanding the stresses and environmental conditions typical in wind power generation.

- Rotary System Components: Forged shafts and cylinders are key in rotary systems, offering the necessary strength and rotational stability.

Key Players in the Industry

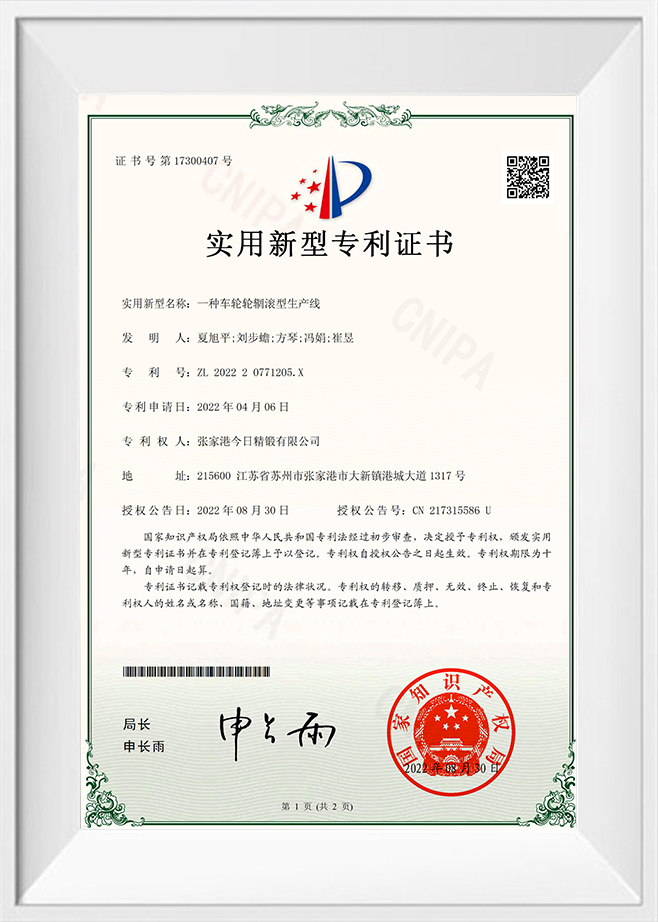

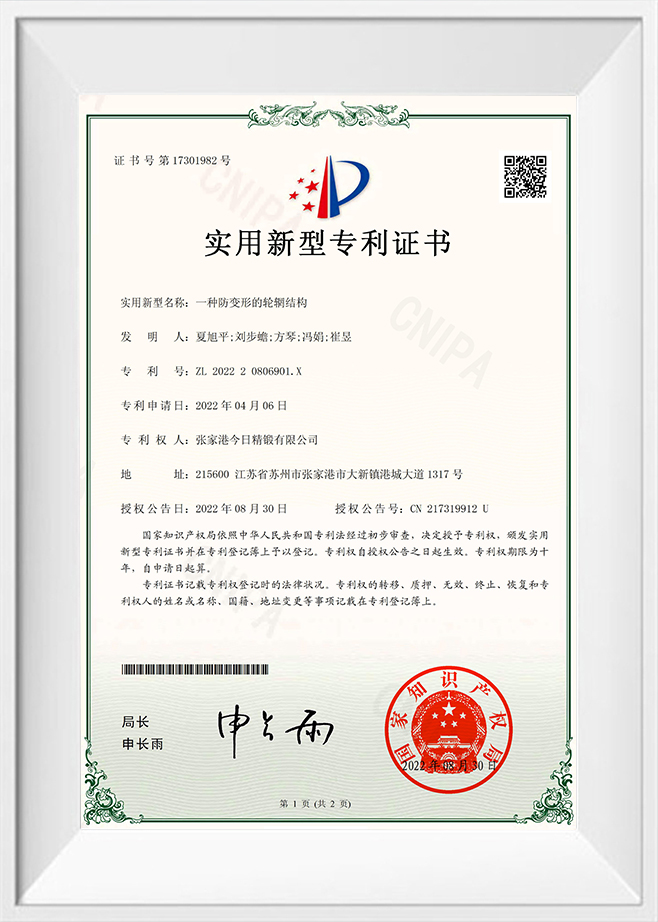

Zhangjiagang Maiterio Intelligent Equipment Company is a significant player in the field of engineering machinery forgings, specializing in seamless rolled rings, forged shafts, forged cylinders, and precision-machined components. The company boasts cutting-edge technology and a well-integrated production line, ensuring high production efficiency and the delivery of top-quality products.

With ISO 9001, ISO 14001, and ISO 45001 certifications, Maiterio adheres to the highest standards in quality control, production processes, and environmental management. This commitment to quality allows them to provide products that meet the most demanding specifications across industries such as power generation, construction, and mining.

The company’s strategic partnerships also give them access to competitive steel pricing, thanks to their relationship with Yong Gang, a leading alloy steel mill in China. This ensures Maiterio can offer their customers both high-quality products and competitive pricing.

Why Choose Forged Components Over Cast or Machined Parts?

The benefits of forging over casting or machining are clear. For instance, forged parts exhibit superior strength and resistance to fatigue, making them ideal for demanding applications. Forging processes also allow for tighter tolerances and more uniform material properties, ensuring the longevity and reliability of the component.

While casting can produce complex shapes at a lower cost, it often sacrifices strength and durability, particularly in high-stress environments. Machining from solid stock can provide precise shapes but at a higher cost and with more material waste.

Conclusion

In summary, engineering machinery forgings play a vital role in modern manufacturing, providing high-performance components that are both strong and durable. These forged parts are crucial in industries such as construction, energy, and transportation, where high loads and continuous stress are common.

English

English Español

Español русский

русский