Carbon Steel Forgings Factory

Zhangjiagang Maiterio Intelligent Equipment Company

Latest Updates

Carbon Steel Industry knowledge

Industry Knowledge: Carbon Steel Forgings Manufacturing Excellence

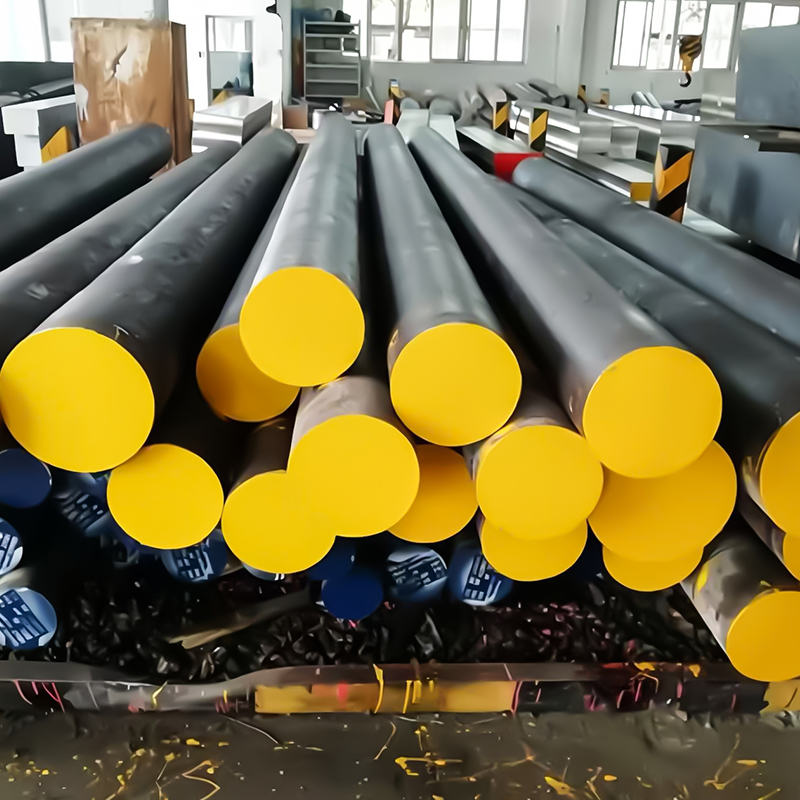

The industrial landscape relies heavily on robust materials, with Carbon Steel Forgings standing as a cornerstone for construction and heavy machinery. This sector demands not only high-quality raw materials but also precision manufacturing processes to ensure structural integrity. Zhangjiagang Maiterio Intelligent Equipment Company, founded in 2019, has rapidly established itself as a leader in this domain. Specializing in seamless rolled rings, forged shafts, forged cylinders, and precision-machining components for high-performance applications, the company operates under strict ISO 9001, ISO 14001, and ISO 45001 standards. Serving global giants such as GE Vernova, Vestas, Caterpillar, Siemens Energy, and Komatsu, Maiterio combines decades of expertise with modern infrastructure to deliver superior forging solutions.

Manufacturing Processes: From Ring Rolling to Open Die Forging

Understanding the production capabilities of a forging facility is essential for selecting the right partner for critical components. Different forging methods offer distinct advantages depending on the geometry and application of the final part.

Production Line Configurations

| Production Line Type | Quantity | Primary Applications | Key Advantage |

| Ring Forging Lines | 3 | Seamless rolled rings, bearing races, flanges | Superior grain structure for cylindrical parts |

| Open Die Forging Lines | 2 | Large shafts, cylinders, custom shapes | Flexibility for large and heavy components |

| Machining Workshops | 2 | Precision finishing and CNC machining | Equipped with over 70 CNC machines |

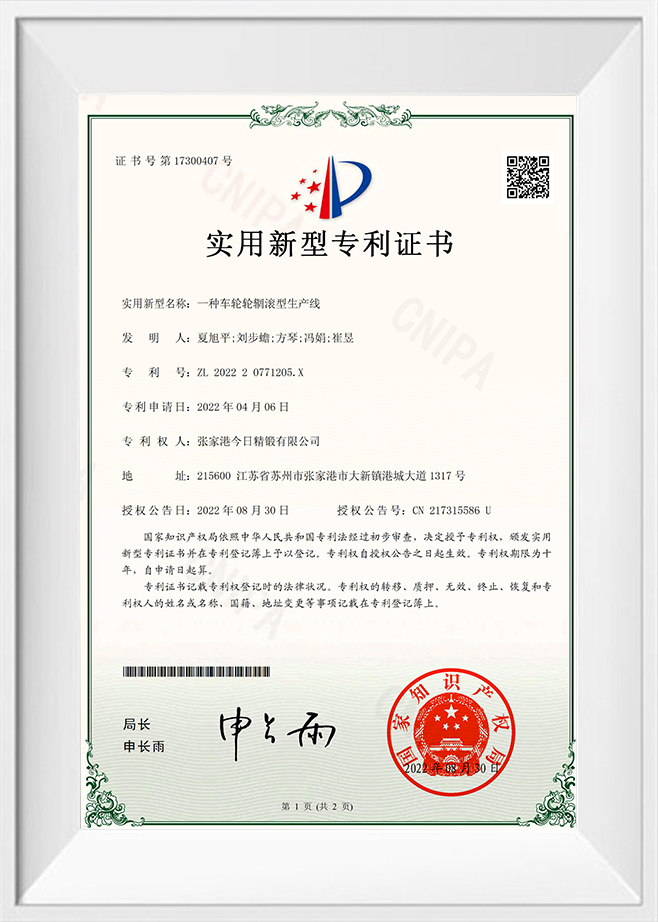

Zhangjiagang Maiterio Intelligent Equipment Company occupies over 50,000 square meters to house these extensive facilities. The core differentiator lies in the design of these lines. Because the founding team consists of industry leaders with over 30 years of experience, they have designed their own forging lines. This user-centric design results in smaller forging allowances and a higher production pace, ensuring that clients receive parts that are closer to net shape and delivered faster.

Material Quality Control and Supply Chain Integration

The quality of Carbon Steel Forgings is intrinsically linked to the quality of the raw steel used. In 2024, Maiterio Group expanded its business scope to include steel trading and forging whole-line solutions. This vertical integration provides a significant competitive edge.

Strategic Material Sourcing

- Top-Tier Partnerships: As the largest customer of Yong Gang (a top 3 alloy steel mill in China), Maiterio secures priority access to high-quality billets.

- Cost Efficiency: Massive internal consumption guarantees the most competitive steel purchase prices in the market.

- Quality Assurance: Quality control is guaranteed by internal consumption standards. Since Maiterio uses this steel for its own high-precision forgings, the material undergoes rigorous testing before processing.

Applications in High-Performance Industries

The reliability of forged components is critical for sectors where failure is not an option. The mechanical properties of carbon steel, such as strength and toughness, make it an ideal choice for demanding environments.

Key Sectors and Components

- Wind Energy: Seamless rolled rings and shafts for GE Vernova and Vestas turbines require exceptional fatigue resistance.

- Heavy Machinery: Caterpillar and Komatsu rely on robust forged parts for excavators and mining equipment.

- Energy Sector: Siemens Energy utilizes high-integrity forgings for power generation applications.

FAQ

What are the main advantages of Carbon Steel Forgings over castings?

Carbon Steel Forgings offer superior mechanical properties compared to castings. The forging process aligns the grain structure of the steel, resulting in enhanced strength, toughness, and ductility. This makes forgings more resistant to impact and fatigue, which is crucial for high-stress applications like those found in the wind energy and heavy machinery sectors served by Zhangjiagang Maiterio Intelligent Equipment Company.

How does ring rolling differ from open die forging for carbon steel components?

Ring rolling is a specialized process used to create seamless rings with a controlled grain flow, ideal for pressure vessels and bearing races. Open die forging, on the other hand, involves deforming steel between flat or simple dies without fully constraining the material; this is best suited for large, custom-shaped components like shafts and cylinders. Maiterio utilizes both methods, operating 3 ring rolling lines and 2 open die lines to cover a broad spectrum of customer needs.

Why is forging allowance important in the manufacturing process?

Forging allowance refers to the excess material left on the forged part for subsequent machining. Smaller forging allowances indicate higher precision in the forging process, reducing the amount of material waste and machining time required. Zhangjiagang Maiterio Intelligent Equipment Company designs its own forging equipment specifically to minimize these allowances, thereby offering cost savings and faster turnaround times to clients without compromising on the structural integrity of the part.

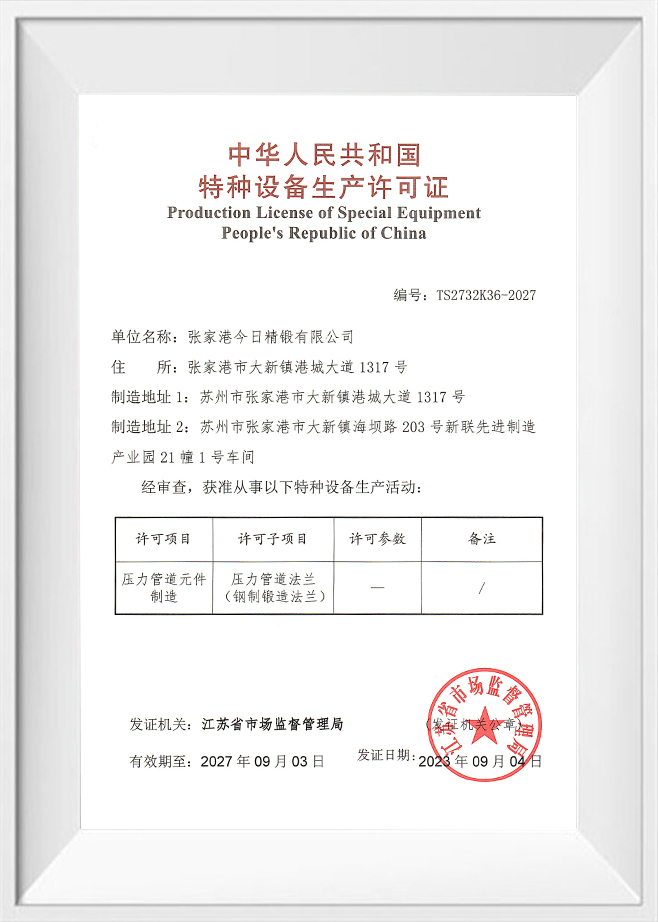

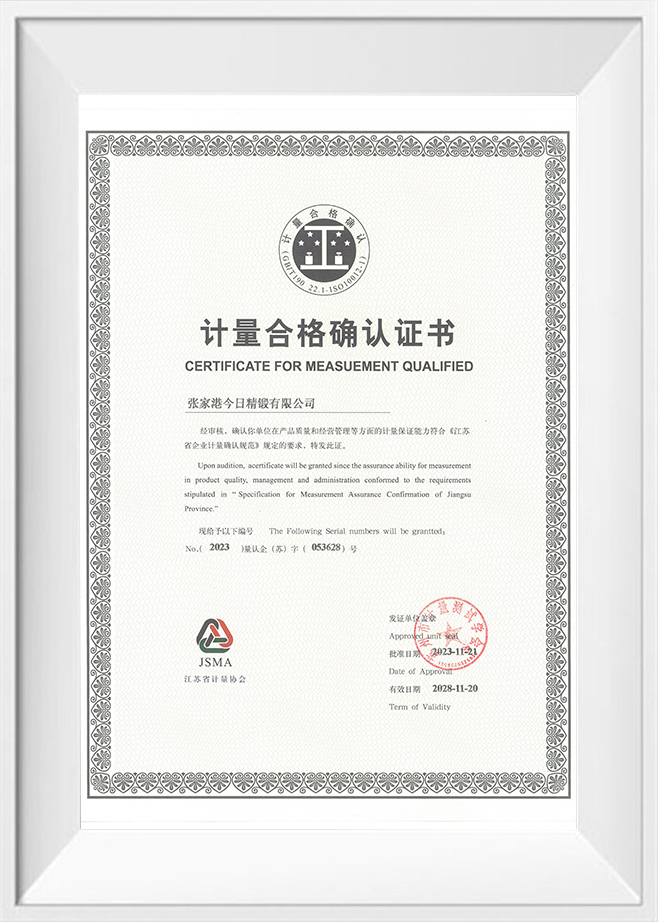

What certifications should a reliable carbon steel forging manufacturer have?

A reliable manufacturer should hold internationally recognized certifications to ensure consistent quality and safety. Zhangjiagang Maiterio Intelligent Equipment Company operates under ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety) standards. These certifications demonstrate a commitment to catering quality control and production processes to the highest global standards, ensuring reliability for end-users like GE Vernova and Siemens Energy.

How does vertical integration benefit buyers of forged components?

Vertical integration, where a manufacturer controls the supply chain from raw material to finished product, offers significant benefits. By incorporating steel trading and forging solutions, Zhangjiagang Maiterio Intelligent Equipment Company can offer more competitive pricing and strictly monitor material quality from the very beginning. This eliminates supply chain volatility and ensures that the carbon steel used meets the exact specifications required for high-performance applications.

English

English Español

Español русский

русский