-

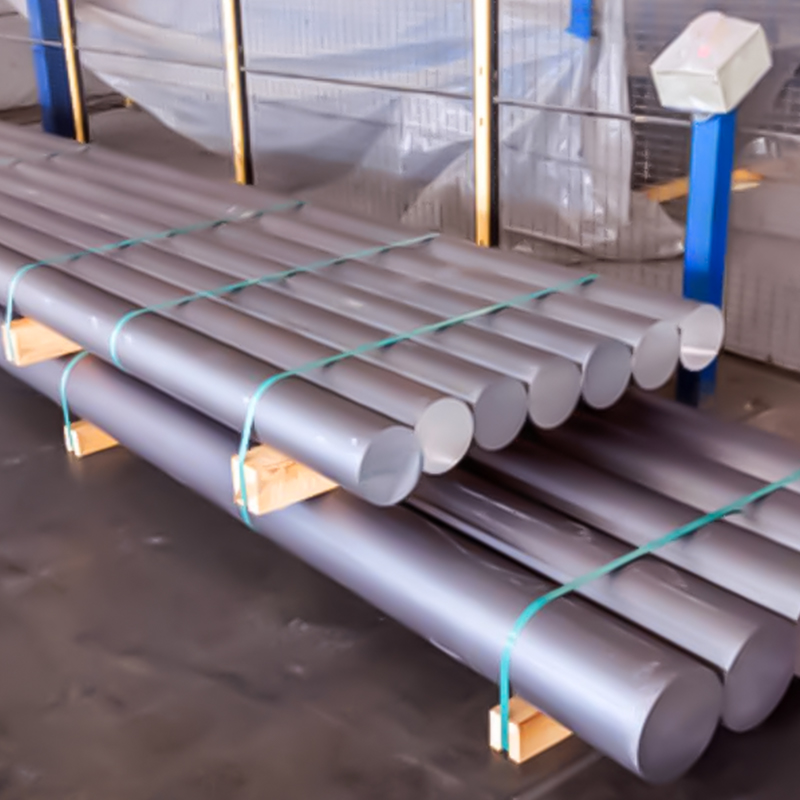

A fundamental steel grade where the primary element is carbon. A good choice for medium mechanical properties and medium budget.View Products

A fundamental steel grade where the primary element is carbon. A good choice for medium mechanical properties and medium budget.View Products -

Carbon steel enhanced with additional alloying elements to improve mechanical properties.View Products

Carbon steel enhanced with additional alloying elements to improve mechanical properties.View Products -

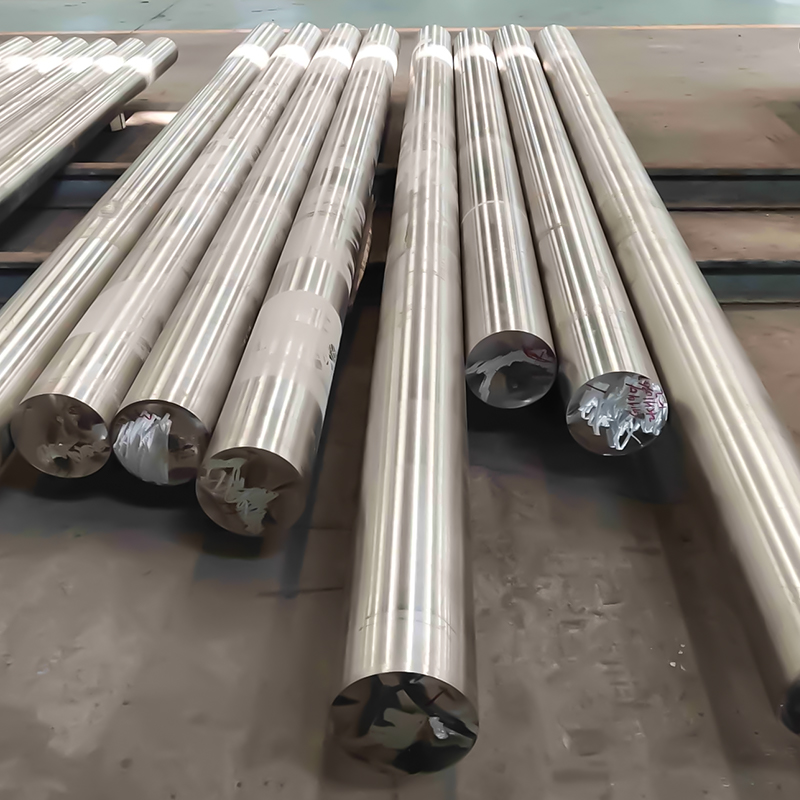

A family of steel alloys defined by a minimum of 10.5% chromium content, which provides inherent corrosion resistance.View Products

A family of steel alloys defined by a minimum of 10.5% chromium content, which provides inherent corrosion resistance.View Products -

A high-performance alloy where Nickel is the primary element, designed to operate in extreme environments.View Products

A high-performance alloy where Nickel is the primary element, designed to operate in extreme environments.View Products

Steel Forgings Supplier

-

A387 Gr.11 CL2/13CrMo4-5/12Cr1MoV alloy steel

A387 Gr.11 CL2/13CrMo4-5/12Cr1MoV alloy steel

-

SAE 52100/100Cr6/GCr15 bearing steel

SAE 52100/100Cr6/GCr15 bearing steel

-

F11/P11/13CrMo4-5/15CrMo alloy steel

F11/P11/13CrMo4-5/15CrMo alloy steel

-

F22/P22/10CrMo9-10/12Cr2Mo alloy steel

F22/P22/10CrMo9-10/12Cr2Mo alloy steel

-

F91/P91/X10CrMoVNb9-1 alloy steel

F91/P91/X10CrMoVNb9-1 alloy steel

-

9260/60SiCr7/60Si2Mn alloy steel

9260/60SiCr7/60Si2Mn alloy steel

-

H13/X40CrMoV5-1/4Cr5MoSiV1 alloy steel

H13/X40CrMoV5-1/4Cr5MoSiV1 alloy steel

-

410/X10Cr13/1Cr13 stainless steel

410/X10Cr13/1Cr13 stainless steel

-

420/X20Cr13/2Cr13 stainless steel

420/X20Cr13/2Cr13 stainless steel

-

420J1/X30Cr13/3Cr13 stainless steel

420J1/X30Cr13/3Cr13 stainless steel

-

420J2/X46Cr13/4Cr13 stainless steel

420J2/X46Cr13/4Cr13 stainless steel

-

F304/X5CrNi18-10 stainless steel

F304/X5CrNi18-10 stainless steel

Industry Knowledge: The Steel Forgings Supply Chain and Advanced Manufacturing

In the industrial manufacturing sector, steel forgings are critical components known for their superior mechanical properties and reliability in demanding applications. For companies like Zhangjiagang Maiterio Intelligent Equipment Company, expertise extends beyond forging itself into integrated supply chain management and production line innovation. Founded in 2019, the company leverages over 30 years of industry leadership to supply seamless rolled rings, forged shafts, and cylinders to global giants in the energy and heavy machinery sectors.

Core Product Categories and Selection

Understanding the distinct material classes is fundamental to selecting the right forging for an application.

| Product Category | Key Characteristics | Typical Application & Advantage |

|---|---|---|

| Carbon Steel Forgings | Carbon as the primary element; offers a balance of mechanical properties and cost. | A cost-effective solution for components requiring medium strength where extreme corrosion resistance is not critical. |

| Alloy Steel Forgings | Carbon steel enhanced with elements like chromium, molybdenum, or nickel. | Used for parts demanding higher strength, toughness, or wear resistance than standard carbon steel can provide. |

| Stainless Steel Forgings | Defined by a minimum of 10.5% chromium, providing inherent corrosion resistance. | Essential for applications in chemical processing, marine environments, or food & beverage where rust resistance is paramount. |

| Nickel-Based Alloy Forgings | Nickel as the primary element, designed for extreme service conditions. | Employed in the most challenging environments, such as high-temperature turbines or highly corrosive chemical reactors. |

Strategic Advantages in the Forging Industry

Leading manufacturers differentiate themselves through vertical integration and deep process knowledge.

Integrated Supply Chain from Mill to Finish

A significant competitive edge comes from controlling the raw material source. As the largest customer of a top-tier alloy steel mill, such manufacturers secure not only competitive pricing but also guaranteed material quality and consistency, which is critical for high-integrity forgings.

Production Line Innovation Driven by Experience

When a forging company designs its own production lines, the benefits are direct:

- Optimized Forging Allowances: Minimized excess material leads to significant savings in both raw material and subsequent machining costs.

- Enhanced Production Pace: Streamlined processes increase throughput and improve delivery lead times.

This user-turned-builder perspective, born from decades of operation, results in uniquely efficient and flexible forging assets.

Certification and Quality for Global Markets

Serving global OEMs requires adherence to the highest standards. Comprehensive certification (ISO 9001, 14001, 45001) and rigorous production process controls are non-negotiable for suppliers to companies like GE Vernova or Siemens Energy, ensuring product traceability and reliability at every step.

FAQ

What is the difference between open die forging and seamless rolled ring forging?

Open die forging involves shaping metal between multiple dies that do not completely enclose the material. It is ideal for large, simple shapes like shafts, cylinders, or custom blocks. Seamless rolled ring forging is a specialized process where a pierced doughnut-shaped preform is rolled and expanded to create a high-strength, continuous grain-structure ring. The choice depends on the final part geometry: rings for bearings, flanges, or gear rings are typically rolled, while large, solid components are open-die forged.

How does alloy steel improve the properties of a forging compared to carbon steel?

While carbon steel's properties rely mainly on carbon content and heat treatment, alloy steels incorporate elements like chromium, nickel, molybdenum, and vanadium. These additions enable:

- Enhanced Hardenability: Deeper and more uniform hardening during heat treatment.

- Improved Strength and Toughness: Higher tensile and yield strength at various temperatures.

- Better Wear and Fatigue Resistance: Increased service life for components under cyclic loads or abrasion.

This makes alloy steel forgings suitable for highly stressed parts in machinery, vehicles, and energy equipment.

Why are nickel-based alloys preferred for extreme environment applications?

Nickel-based alloys offer an exceptional combination of properties that stainless steels often cannot match:

- High-Temperature Strength: They retain significant mechanical strength and resist creep (deformation under constant load) at temperatures above 1000°C.

- Superior Corrosion Resistance: They perform in highly oxidizing atmospheres and aggressive chemical environments that would degrade other metals.

- Excellent Fatigue Resistance: Vital for components in aerospace engines and power generation turbines subjected to extreme thermal cycling.

What factors determine the cost of a custom steel forging?

The cost is influenced by a complex interplay of factors:

- Material: Alloy and nickel-based steels are more expensive than carbon steels.

- Part Weight and Forging Allowance: Heavier parts and less efficient designs requiring more material to be machined away increase cost.

- Production Volume: High-volume runs amortize setup and die costs, lowering the unit price.

- Geometric Complexity and Tolerances: Complex shapes and tighter "as-forged" tolerances require more sophisticated processes and tooling.

- Testing and Certification Requirements: Stringent non-destructive testing (NDT) or material traceability add to the quality assurance cost.

What are the key quality certifications to look for in a steel forging supplier?

Reputable suppliers hold certifications that audit their systems, not just their products. The most critical include:

- ISO 9001: Certifies a robust Quality Management System ensuring consistent product quality and continuous improvement.

- Industry-Specific Approvals: Certifications from major energy (e.g., Nadcap for aerospace, ASME for pressure vessels) or automotive OEMs, which often involve rigorous on-site audits.

- Environmental & Safety Standards (ISO 14001/45001): Indicate a professionally managed operation committed to sustainability and workforce safety, which correlates with operational stability and reliability.

A supplier's long-term partnerships with major global companies are a strong testament to their certified quality systems in practice.

English

English Español

Español русский

русский