Production Overview

Blanking Equipment

We strictly follow customers’ requirements to purchase raw materials from qualified suppliers. We can also provide suggestions on which steel mill is more reliable and experienced in specific grade of raw material.

We have plenty raw material in stock to ensure quick production and on-time delivery.

Adhering to strict quality control policies, we carry out 100% chemical component test on raw material as per the technical agreement.

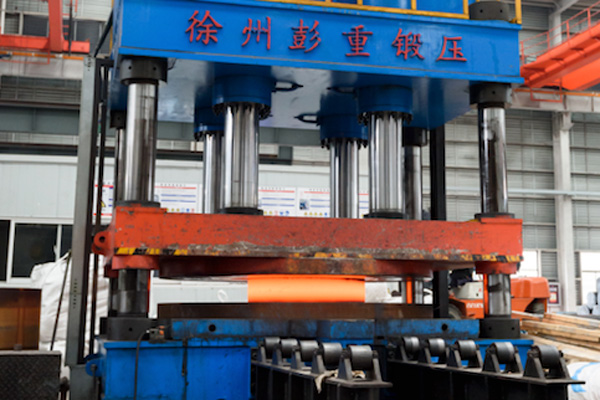

Forging Equipment

We have different sizes of ring rolling machines, electro-hydraulic hammer, air hammer and press to better satisfy our customers’ requirements. Suitable machines will bring lower cutting weight and higher dimensional accuracy.

We strictly control the forging process to meet the forging ratio as per the technical agreement.

Heat Treatment Equipment

We have advanced heat treatment equipment in the industry, strictly monitoring and controlling and heating temperature, holding time and cooling rate to meet our customers’ requirements.

We monitor the purity and temperature of the quenching medium, so as to eradicate all harmful factors.

Machining Equipment

Full set of machining capabilities to satisfy our customers’ requirements: CNC vertical and horizontal lathes, CNC boring machines, Dual column lathe, radial drill.

We keep regular and routine maintenance of our machines to ensure high precision and normal operations.

Inspection Equipment

We have the full set of inspection capabilities in house: German SPAX Spectrometer/Impact Test Gap Projector/Tensile Strength Testing/Metalloscope/Impact Toughness Testing/ UT testing/Magnetic Particle testing.

For our strategic partners’ product offerings, we will have our professional inspection team to conduct a third-party quality inspection before packing and shipping to our customers.