-

A specialized forging process that produces seamless rolled rings from a hollow circular preform.View Products

A specialized forging process that produces seamless rolled rings from a hollow circular preform.View Products -

A forging process where heated material is shaped between multiple flate or simple contoured dies without confining the material entirely.View Products

A forging process where heated material is shaped between multiple flate or simple contoured dies without confining the material entirely.View Products -

The forging of rare and difficult-to-process materials that possess unique properties.View Products

The forging of rare and difficult-to-process materials that possess unique properties.View Products

Seamless Rolled Ring Forging Supplier

Seamless Rolled Ring Forging Manufacturing Principles and Industrial Value

Seamless rolled ring forging is a metal forming process used to produce high strength ring components with uniform structure and stable performance. Compared with welded rings or cut rings, seamless rolled rings provide better load capacity, fatigue resistance, and dimensional consistency. This makes them suitable for demanding industrial applications where reliability and long service life are required.

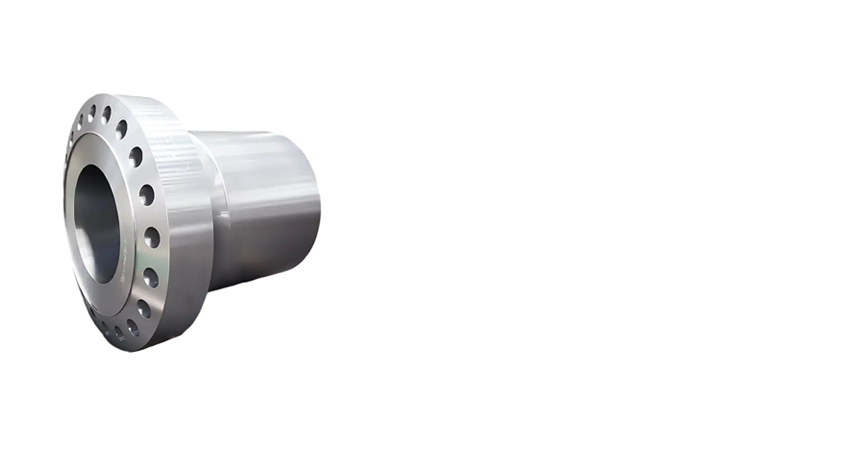

Seamless rolled ring forgings are commonly used for bearing rings, flanges, gear rings, pressure vessel components, and other circular parts that operate under high stress, vibration, or temperature variation.

How Seamless Rolled Ring Forging Works

The process starts from a solid forged billet. After heating, the billet is pierced to form a hollow ring blank. This blank is then placed on a ring rolling mill, where radial and axial forces are applied to gradually expand the diameter while reducing wall thickness. During this process, the metal grain flows continuously along the ring circumference.

This forming method allows precise control of ring dimensions and helps achieve stable mechanical properties throughout the entire ring.

Main Advantages of Seamless Rolled Ring Forging

| Aspect | Seamless Rolled Ring Forging | Welded or Cut Rings |

|---|---|---|

| Grain structure | Continuous grain flow following ring shape | Interrupted grain flow |

| Mechanical strength | High fatigue resistance and load capacity | Lower fatigue performance |

| Structural integrity | No weld seams or joints | Weld seam may weaken structure |

| Dimensional stability | Good roundness and uniform thickness | Higher risk of deformation |

| Service life | Suitable for long term and critical use | Limited in high stress conditions |

Common Materials for Seamless Rolled Ring Forgings

Material selection is essential to ensure performance under specific working conditions. Seamless rolled ring forgings can be produced in a wide range of materials according to design and industry standards.

| Material type | Typical grades | Application characteristics |

|---|---|---|

| Carbon steel | A105 C45 | General structural use with good machinability |

| Alloy steel | 42CrMo 34CrNiMo6 | High strength and fatigue resistance |

| Stainless steel | 304 316 410 | Corrosion resistance for pressure systems |

| Low temperature steel | ASTM A350 LF2 | Stable performance in cold environments |

| Heat resistant alloys | Custom grades | Used in high temperature conditions |

Typical Industrial Applications

Seamless rolled ring forgings are widely used across industries that require strong and reliable circular components.

In wind power systems, they are used for main bearing rings and yaw or pitch system components. In oil and gas projects, they are applied to flanges and pressure retaining rings. Construction machinery relies on forged rings for slewing systems and transmission parts. Heavy equipment and industrial bearing manufacturers also use seamless rolled rings for structural and rotating components.

Manufacturing Capability and Dimensional Control

A capable seamless rolled ring forging supplier should support flexible sizes, materials, and machining requirements. Important production factors include diameter range, wall thickness control, heat treatment, and machining accuracy.

Zhangjiagang Maiterio Intelligent Equipment Company operates multiple ring forging and open die forging lines, supported by machining workshops equipped with over seventy CNC machines. This allows the supply of rough forged rings as well as fully machined components based on customer drawings.

Quality Control in Seamless Rolled Ring Forging

Quality control is applied throughout the production process to ensure consistency and reliability. This includes chemical composition inspection of raw materials, controlled forging temperature, ultrasonic testing for internal defects, dimensional inspection, and mechanical property testing when required.

These measures help meet international standards and support stable performance in long term industrial use.

Frequently Asked Questions

What is the difference between seamless rolled ring forging and open die forging

Seamless rolled ring forging is designed specifically for ring shaped parts with controlled expansion and uniform grain flow. Open die forging is more suitable for shafts blocks or bars rather than precision rings.

Can seamless rolled rings be supplied with machining

Yes forged rings can be delivered in rough forged condition or fully machined according to drawings including turning drilling and surface finishing.

Which industries benefit most from seamless rolled ring forgings

Industries such as wind energy oil and gas and heavy machinery benefit due to the need for high fatigue strength and dimensional stability.

Are custom sizes and materials available

Custom diameters wall thicknesses and material grades are commonly supported for OEM and long term supply projects.

Importance of Seamless Rolled Ring Forging for Long Term Performance

As industrial equipment continues to grow in size and complexity, the demand for reliable and durable components increases. Seamless rolled ring forging provides a balanced solution with strong mechanical properties and precise dimensions.

By combining forging experience with machining and inspection capability, Zhangjiagang Maiterio Intelligent Equipment Company supports customers seeking stable performance in high load and long service applications.

English

English Español

Español русский

русский