In the metal materials field, C45 and 42CRMO4 and are two commonly - used steel grades. Thoroughly understanding their performance differences is crucial for proper material selection and product design optimization.

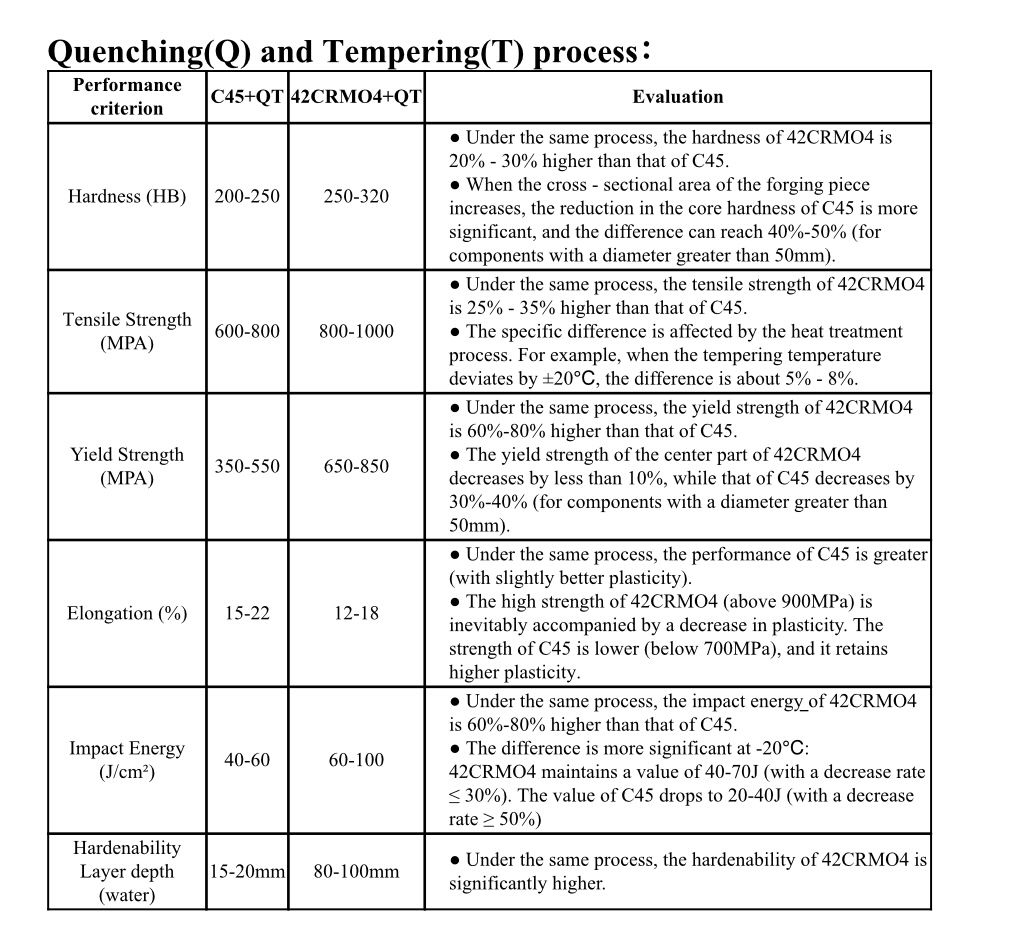

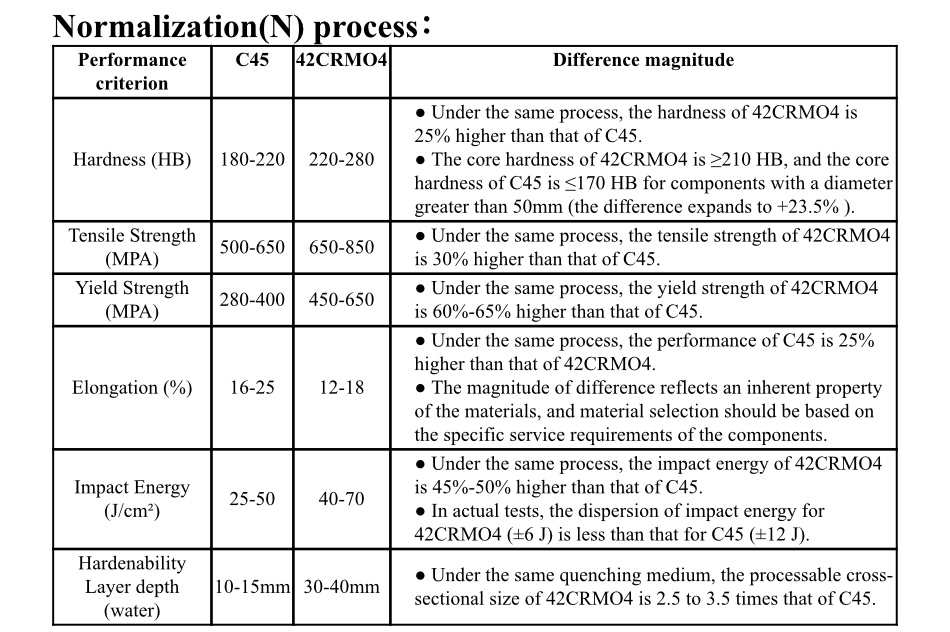

Mechanical Property Comparison

Note: All the above data are subject to fluctuations influenced by component size, heating/cooling environments, and processes (such as air cooling, forced air cooling, etc.).

In mechanical engineering, material selection is a critical decision that balances performance, cost, and operational requirements. The following will detail the application contexts, advantageous scenarios, and inherent characteristics of C45 and 42CRMO4 to guide clients in making more appropriate choices.

C45: Cost-saving decisions for low and medium performance requirements

Scenario Selection Criteria

· Low/Medium Load: Static or stable low-speed operation (rotational speed < 500 rpm).

· Mild Environment: Operating temperature < 80°C, with no or slight corrosion.

· Non-Critical Components: Auxiliary bearings or support structures without safety-critical requirements.

Advantages

· Low cost: Economical for large-scale manufacturing and replacement parts.

· Excellent machinability: Easy to cut, shape, and form, reducing production time.

· Good weldability: Simplifies assembly with other components.

· Simple heat treatment: Basic processes like surface quenching or tempering suffice for most applications.

· Sufficient small-size performance: Meets mechanical requirements for small components.

Limitations

· Extremely poor hardenability: Core hardness degrades drastically in large cross-sections.

· Limited strength: Inadequate for high-load or dynamic stress scenarios.

· Insufficient toughness: Prone to brittle failure under impact or sudden load changes.

· Short fatigue life: Unsuitable for components with frequent stress cycles.

· Dramatic large-section performance drop: Mechanical properties decline significantly as size increases.

C45 shines in cost-sensitive applications where moderate performance and economic efficiency take precedence. The following real-world cases illustrate how it balances cost and functionality effectively:

Typical Application Scenarios

· Agricultural machinery pulley bearings

· Small conveying roller bearings

· Household appliance shaft support bearings

· Non-core bearings in low-cost automation equipment

· Coupling flanges and M12-M30 high-strength bolts (8.8 grade)

| Case 1 | Agricultural Tractor Drive Shaft (Φ40mm, 500 Hours/Year Operation)

| | Reason for Selection: In stable-load scenarios with strict cost control, quenched and tempered C45 delivers optimal strength and wear resistance without the need for over-engineered materials. Its reliability in low-speed, non-critical components makes it the ideal choice for agricultural machinery, where life-cycle costs are a key consideration.

| Case 2 | Warehouse Conveying Roller (Φ60mm, 30 rpm)

| | Reason for Selection: For low-stress, low-speed applications requiring basic wear resistance. Surface quenching alone meets the roller’s operational demands, eliminating the need for high-performance alloys and achieving a 70% reduction in material costs—an excellent example of cost-effective material selection in industrial automation.

42CRMO4: High-Performance Necessity for Demanding Scenarios

Scenario Selection Criteria

· High/Impact Load: Components in mining machinery, wind turbines, or marine equipment under heavy dynamic loads.

· Large Cross-Section: Bearings with inner diameter > 50mm or parts requiring consistent core performance.

· Harsh Environment: High temperature (<300℃), corrosive media, or high-frequency alternating stress.

· Long-Life Requirements: Design life > 50,000 hours or >10⁷ stress cycles.

Advantages

· Ultra-high strength: Withstands extreme static and dynamic loads without deformation.

· Excellent hardenability: Maintains uniform core hardness in large sections, critical for components like heavy-duty bearings.

· Superior toughness: Resists cracking under impact and cyclic stress, essential for mining and aerospace applications.

· Outstanding fatigue performance: Meets rigorous long-life standards, reducing maintenance and failure risks.

· Uniform large-section performance: Eliminates core-outer property disparities in thick components.

Limitations

· High cost: Premium alloy composition and specialized processing increase material and manufacturing expenses.

· Difficult machining: Requires advanced tools and techniques due to its high strength.

· Complex welding process: Strict heat control is necessary to avoid structural defects.

· High thermal sensitivity: Susceptible to micro-structural changes during overheating, affecting mechanical properties.

· Risk of excessive performance: May be uneconomical for non-critical applications where its capabilities are unnecessary.

42CRMO4 is indispensable in heavy-load applications where extreme strength, durability, and reliability are required. The following cases demonstrate how its unique properties address critical engineering challenges that lower-grade steels like C45 cannot resolve:

Typical Application Scenarios

· Wind turbine main shaft bearings

· Heavy-duty truck hub bearings

· Metallurgical mill roll bearings

· Aircraft engine auxiliary drive bearings

· Shield machine cutter head connecting shafts

| Case 1 | 2MW Wind Turbine Main Shaft (Φ600mm, 20-Year Design Life)

| | Reason for Selection: In large-diameter components requiring decades of reliable service, 42CRMO4 ensures the core has a 0.2% offset yield strength (σ₀.₂) of at least 650 MPA—a requirement C45 cannot meet due to its drastic strength degradation in thick sections. Failure risks are catastrophic here, and material performance must withstand constant dynamic loads over extended lifetimes.

| Case 2 | Petroleum Drill Pipe Joint (Subject to 2000kN Tensile-Compressive Cyclic Load)

| | Reason for Selection: In high-cycle stress environments like oil and gas drilling, 42CRMO4’s fatigue limit (2.3 times that of C45) is critical for preventing cracking failures. The drill pipe joint must endure millions of tensile-compressive cycles without fatigue cracking—a demand that 42CRMO4’s outstanding fatigue resistance and toughness can satisfy. This makes it the mandatory choice for components where safety, reliability, and long-term performance are non-negotiable.

Conclusion

The selection between C45 and 42CRMO4 ultimately hinges on the alignment of material properties with application-specific requirements:

· C45 is optimally suited for components characterized by small dimensions, low-load conditions, and short operational lifespans, where its cost-efficiency provides a decisive advantage.

· 42CRMO4 becomes indispensable in scenarios demanding heavy loads, large cross-sectional geometries, and extended service lifetimes. While its initial investment is higher, its superior mechanical performance—including enhanced strength, hardenability, and fatigue resistance—typically results in lower total lifecycle costs by minimizing maintenance interventions, replacement cycles, and failure-related risks.

Material selection must transcend simplistic cost comparisons; instead, environmental service conditions, design lifecycle expectations, and anticipated maintenance requirements must be systematically evaluated. Referencing the application scenarios and technical cases outlined above enables engineers to avoid both performance over-engineering (leading to unnecessary expenditure) and inadequate mechanical properties (compromising structural integrity or operational reliability). By rigorously matching material capabilities to functional demands, stakeholders can achieve an optimal balance between economic efficiency and technical performance, ensuring that industrial designs adhere to both budgetary constraints and safety-critical specifications over their intended service lives.